UM094TW / UM594TW UDM094-04

42

TROUBLESHOOTING CONTINUED

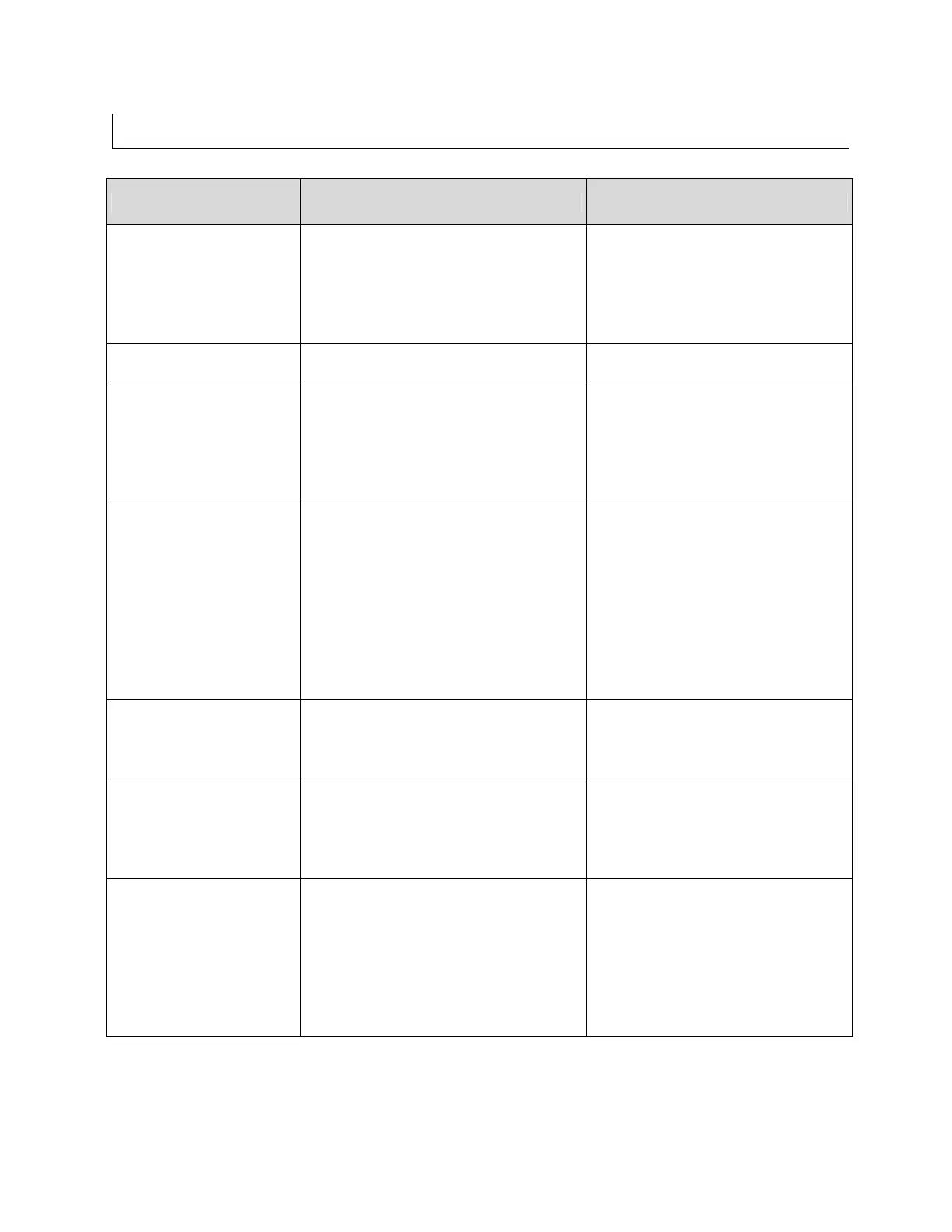

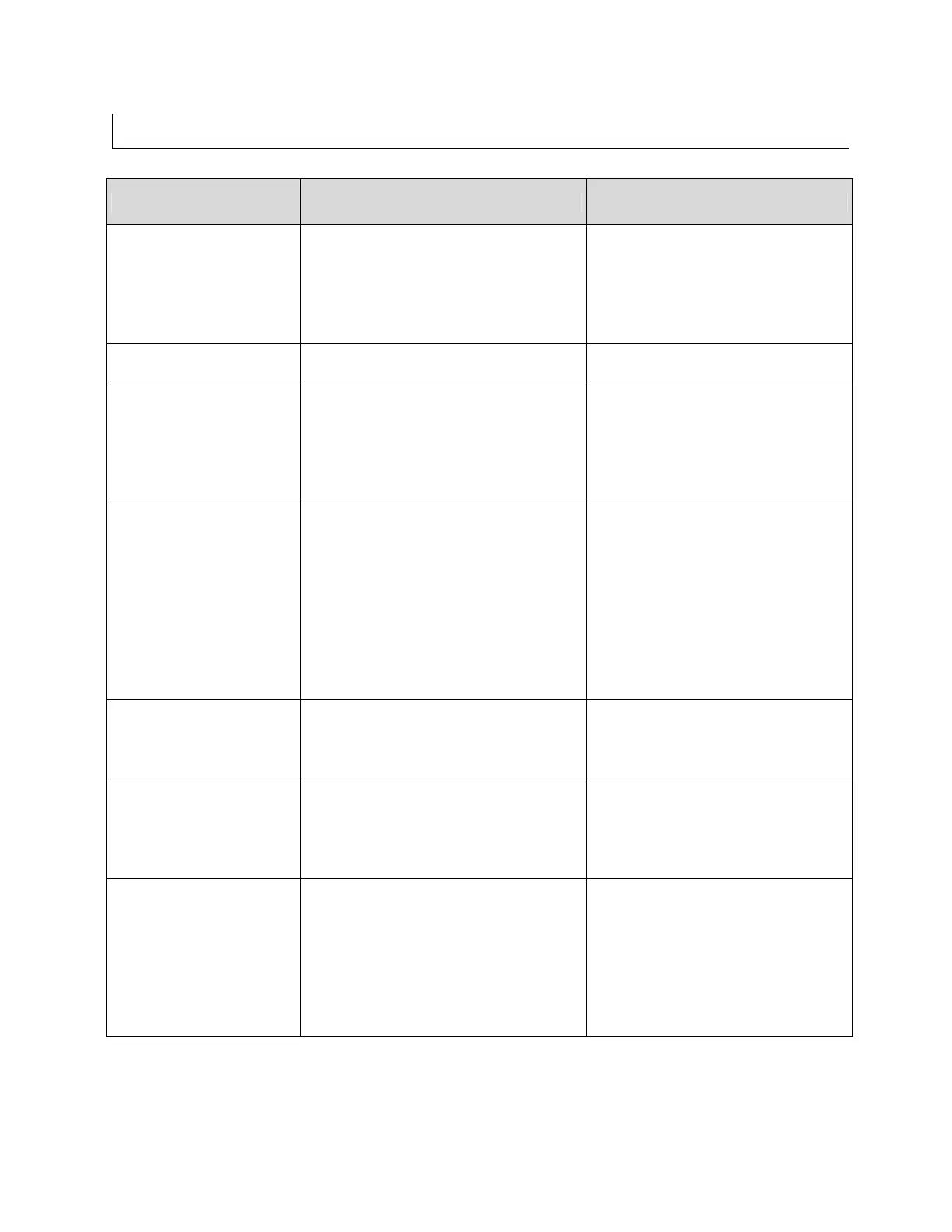

Trouble Possible Causes Solutions

Case Processes But

Leading End Panel Is

Crushed

Product Does Not Support The End

Panel Of The Case

Main Spring Tension On Tape Head

Too Strong

Insert Proper Dunnage Material

To Provide Support

Reduce Main Spring Tension.

See Tape Head Manual Provided

With Tape Head

Drive Belts Start, Then

Stop

Motor Starter Trips Call Maintenance

Void Fill Cases Do Not

Process Properly

Upper Tape Head Wipe Down

Rollers Collapse Inside Case.

-Install Lighter Gauge Tape Head

Main Spring

-Reduce Unwind Tension On

Tape Roll

a. Mandrel Tension

b. Clutch Roller Tension

Overfilled Cases Do

Not Process Properly

Product Height Exceeds Case

Height

Excessive Void Fill Dunnage.

Top Tape Head Box Is Not Adjusted

Properly

-Reduce Product In Case To

Match Case height

-Increase Case Height To Match

Product Height.

Reduce Void Fill Dunnage to

Match Case Height

Readjust Top Tape Head Box To

Proper Case Height

Unstable Cases Do not

Process Properly

Case Height Exceeds 1 ½ Times

The Case Length

-Re-Configure Case Dimensions

So That Case Is Not Unstable

-Process Case On Top and

Bottom Belt Drive Machine

Tape Not Centered on

Carton

Tape Roll Mandrel Not Centered on

Case.

Tape Roll Not Fully Pushed On

Tape Mandrel.

Center Tape Roll Mandrel, See

Tape Head Manual.

Push Tape Roll Completely Onto

Tape Mandrel.

Tape Leg Is Too Short /

Too Long

Tape Leg Adjustment Not Correct.

Tape Head Is Not Threaded

Correctly

Tape Roll Unwind Tension Is Too

Strong Or too Weak.

Adjust Tape Leg, See Tape Head

Manual.

Thread Tape Head Correctly,

See Section 7 page 33.

Adjust Unwind Tension, See

Tape Head Manual.

Loading...

Loading...