Optidrive ODE-3 1Ph Output User Guide Revision 1.00

6. Parameters

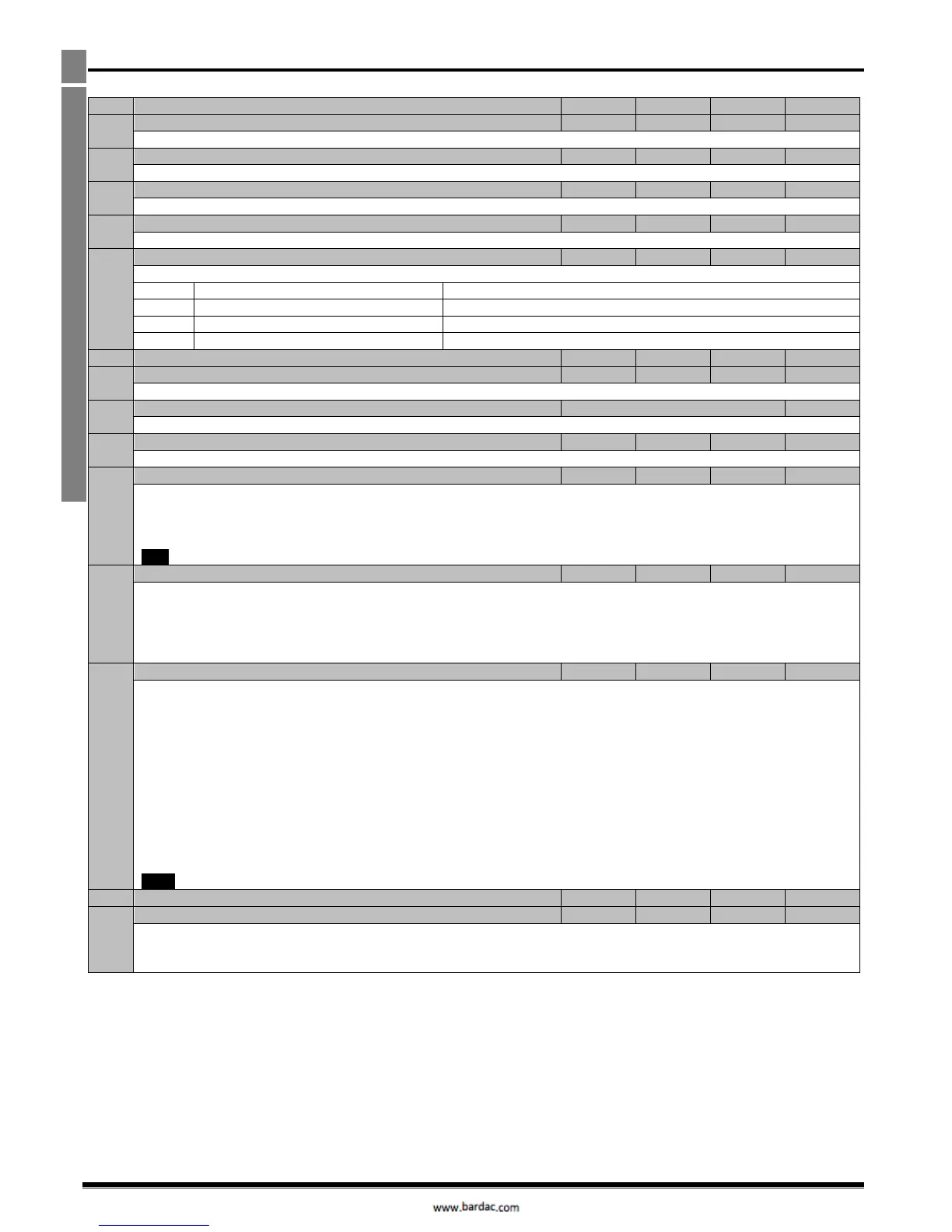

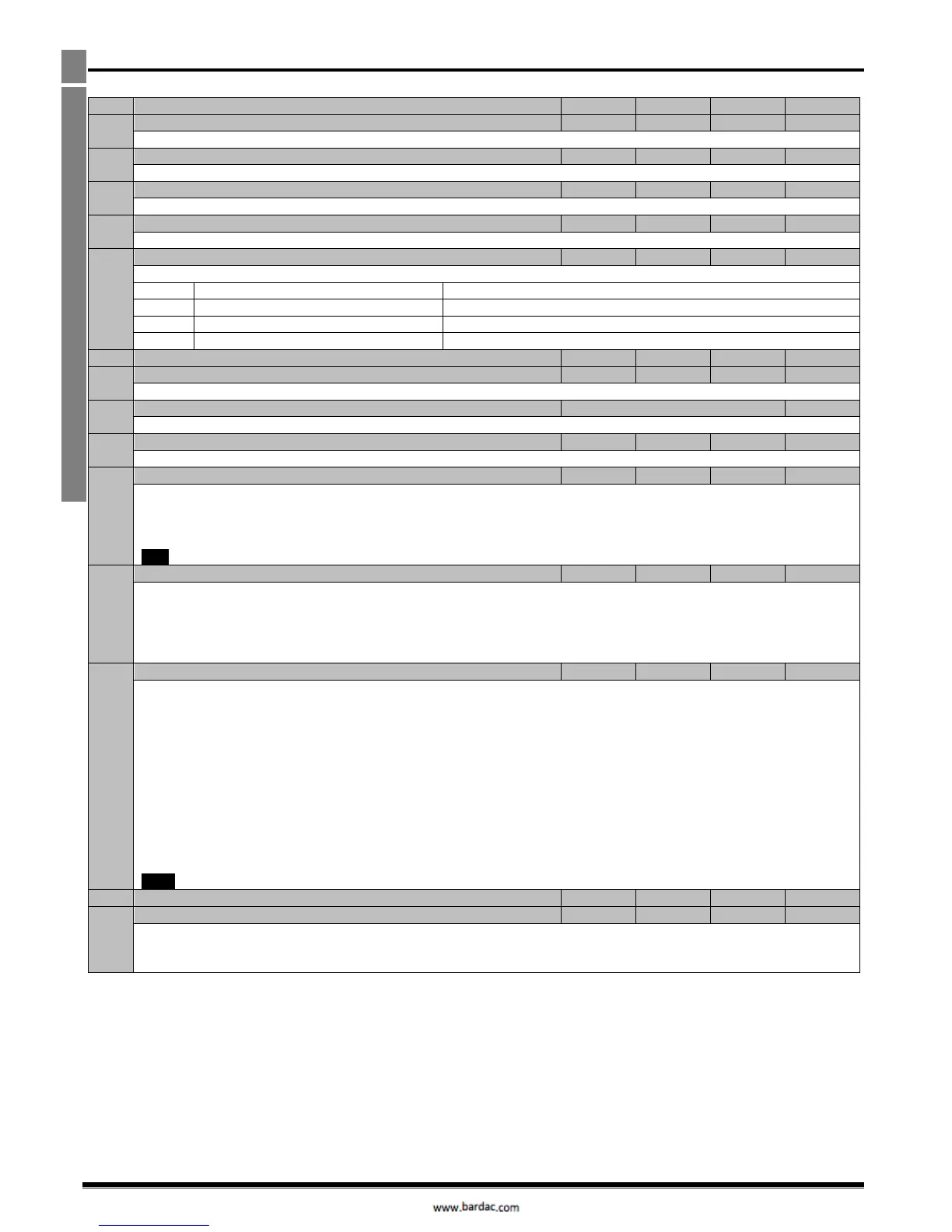

6.1. Standard Parameters

Maximum Frequency / Speed Limit

Maximum output frequency or motor speed limit – Hz or RPM. If P-10 >0, the value entered / displayed is in RPM

Minimum Frequency / Speed Limit

Minimum speed limit – Hz or RPM. If P-10 >0, the value entered / displayed is in RPM

Acceleration ramp time from zero Hz / RPM to base frequency (P-09) in seconds.

Deceleration ramp time from base frequency (P-09) to standstill in seconds. When set to 0.00, the value of P-24 is used.

Stopping Mode / Mains Loss Response

Selects the stopping mode of the drive, and the behaviour in response to a loss of mains power supply during operation.

Ride Through (Recover energy from load to maintain operation)

Fast Ramp to Stop (P-24), Coast if P-24 = 0

This parameter should be set to the rated (nameplate) voltage of the motor (Volts).

This parameter should be set to the rated (nameplate) current of the motor

This parameter should be set to the rated (nameplate) frequency of the motor

This parameter can optionally be set to the rated (nameplate) RPM of the motor. When set to the default value of zero, all speed

related parameters are displayed in Hz and the slip compensation (where motor speed is maintained at a constant value regardless

of applied load) for the motor is disabled. Entering the value from the motor nameplate allows the Optidrive to display motor speed

in RPM. All speed related parameters, such as Minimum and Maximum Speed, Preset Speeds etc. will also be displayed in RPM.

Note If P-09 value is changed, P-10 value is reset to 0

This parameter sets the initial voltage applied to the motor following a start command. The inverter applied the voltage set in this

parameter at the frequency set in P-32 initially, and then ramps to the motor rated voltage set in P-09 over the time period set in P-

33. Excessive voltage boost levels may result in increased motor current and temperature, and can result in the drive tripping during

starting.

An explanation of the motor starting, and procedure for optimising the boost voltage is described in section 6.4.

0: Terminal Control. The drive responds directly to signals applied to the control terminals.

1: Uni-directional Keypad Control. The drive can be controlled in the forward direction only using the internal keypad, or an

external remote Keypad.

2: Uni-directional Keypad Control. The drive can be controlled in the forward direction only using the internal keypad, or an

external remote Keypad.

3: Modbus Network Control. Control via Modbus RTU (RS485) using the internal Accel / Decel ramps

4 : Modbus Network Control. Control via Modbus RTU (RS485) interface with Accel / Decel ramps updated via Modbus

5 : PI Control. User PI control with external feedback signal

6 : PI Analog Summation Control. PI control with external feedback signal and summation with analog input 1

7 : CAN open Control. Control via CAN (RS485) using the internal Accel / Decel ramps

8 : CAN open Control. Control via CAN (RS485) interface with Accel / Decel ramps updated via CAN

9 : Slave Mode. Control via a connected Invertek drive in Master Mode. Slave drive address must be > 1.

NOTE When P-12 = 1, 2, 3, 4, 7, 8 or 9, an enable signal must still be provided at the control terminals, digital input 1

Extended Menu Access code

Enables access to Extended and Advanced Parameter Groups. This parameter must be set to the value programmed in P-37 (default:

101) to view and adjust Extended Parameters and value of P-37 + 100 to view and adjust Advanced Parameters. The code may be

changed by the user in P-37 if desired.

Loading...

Loading...