Optidrive ODE-2 User Guide Revision 3.30

4.6. Motor Thermal overload Protection.

4.6.1. Internal Thermal Overload Protection.

The drive has an in-built motor thermal overload function; this is in the form of an “I.t-trP” trip after delivering >100% of the value set in P-08

for a sustained period of time (e.g. 150% for 60 seconds).

4.6.2. Motor Thermistor Connection

Where a motor thermistor is to be used, it should be connected as follows :-

Additional Information

Compatible Thermistor : PTC Type, 2.5kΩ trip level

Use a setting of P-15 that has Input 3 function as External Trip, e.g. P-15 = 3. Refer to section 7 for

further details.

4.7. Control Terminal Wiring

All analog signal cables should be suitably shielded. Twisted pair cables are recommended.

Power and Control Signal cables should be routed separately where possible, and must not be routed parallel to each other.

Signal levels of different voltages e.g. 24 Volt DC and 110 Volt AC, should not be routed in the same cable.

Maximum control terminal tightening torque is 0.5Nm.

Control Cable entry conductor size: 0.05 – 2.5mm

2

/ 30 – 12 AWG.

4.8. Connection Diagram

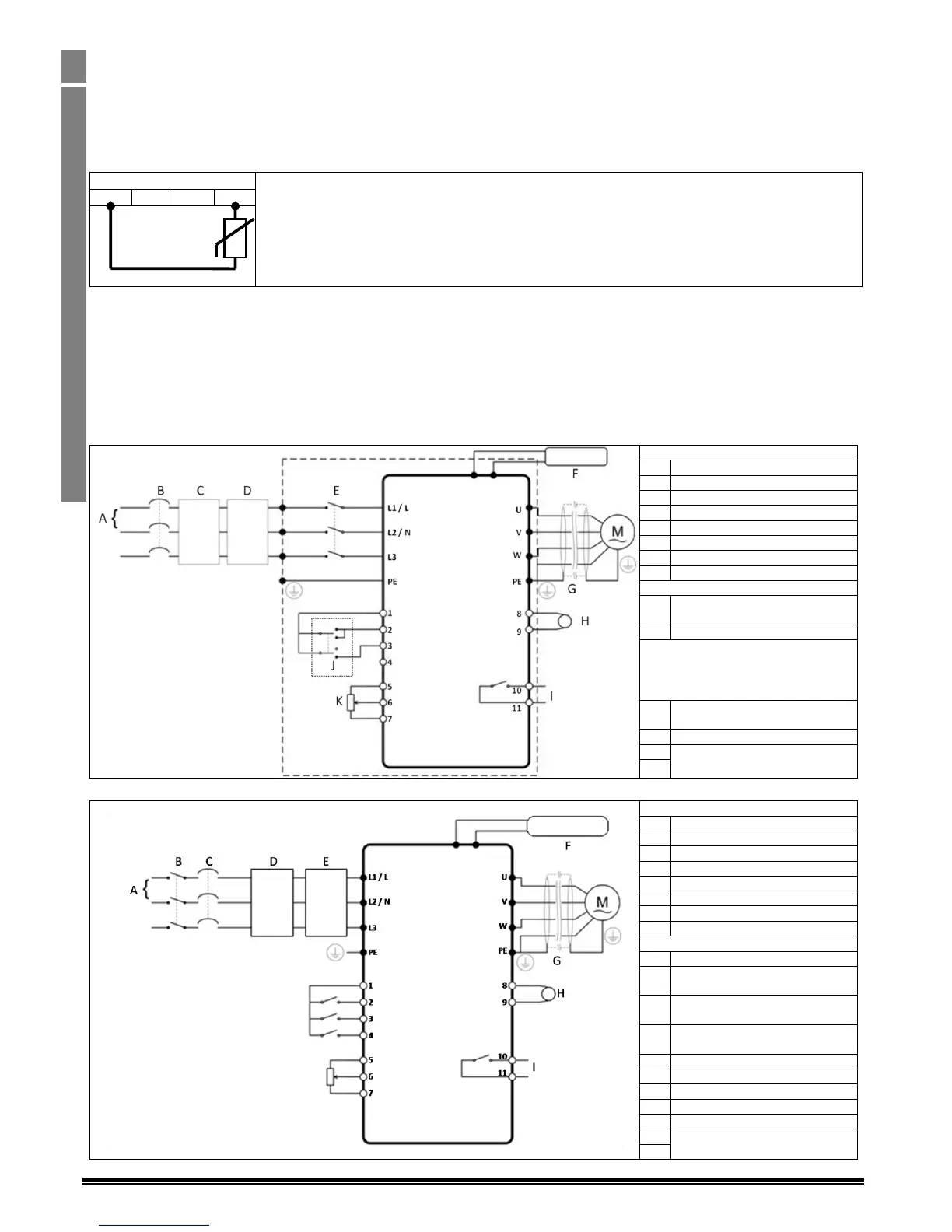

4.8.1. IP66 (Nema 4X) Switched Units

Internal Isolator / Disconnect

Internal Forward / Off / Reverse

Switch

Internal Speed Control Pot

Analog Output

0 – 10 Volts

Relay Output

‘Drive Healthy’ = Closed

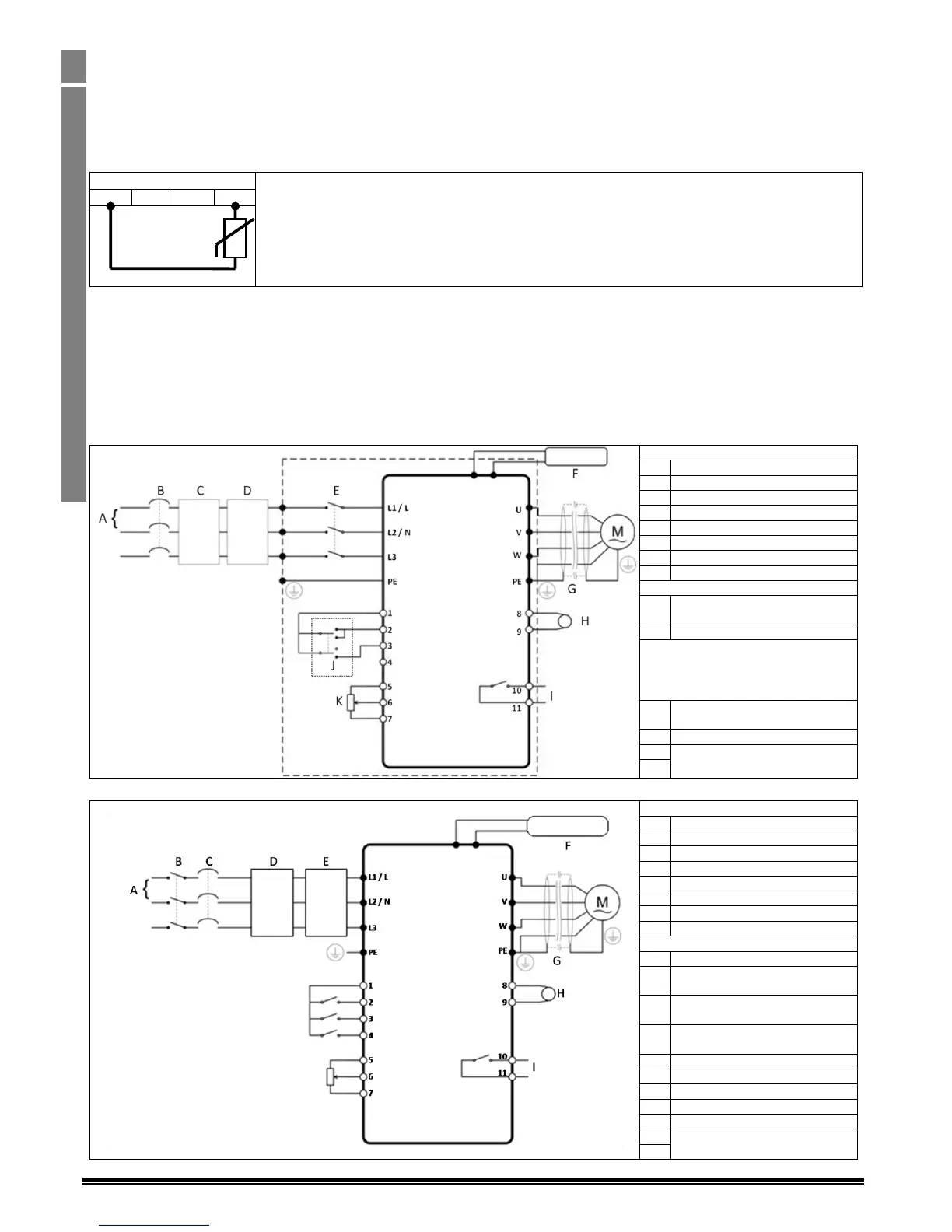

4.8.2. IP20 & IP66 (Nema 4X) Non- Switched Units

+ 24 Volt (100mA) User Output

Digital Input 1

Drive Run / Stop

Digital Input 2

Forward / Reverse

Digital Input 3

Analog / Preset Speed

Analog Output 0 – 10 Volts

Relay Output

‘Drive Healthy’ = Closed

Loading...

Loading...