Goodrive10 Series Mini VFD Fault tracking

-76-

6 Fault tracking

6.1 Fault prevention

This chapter describes how to perform preventive maintenance on the VFD.

6.1.1 Maintenance intervals

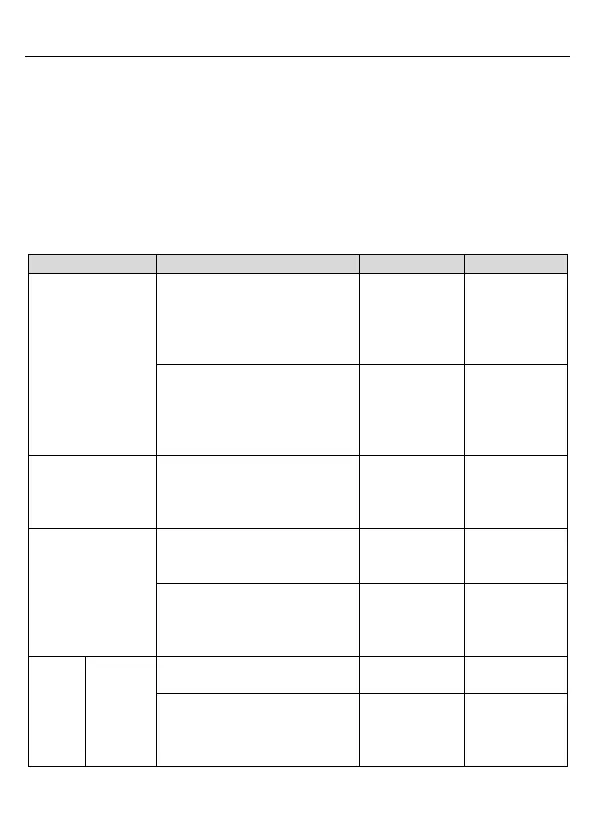

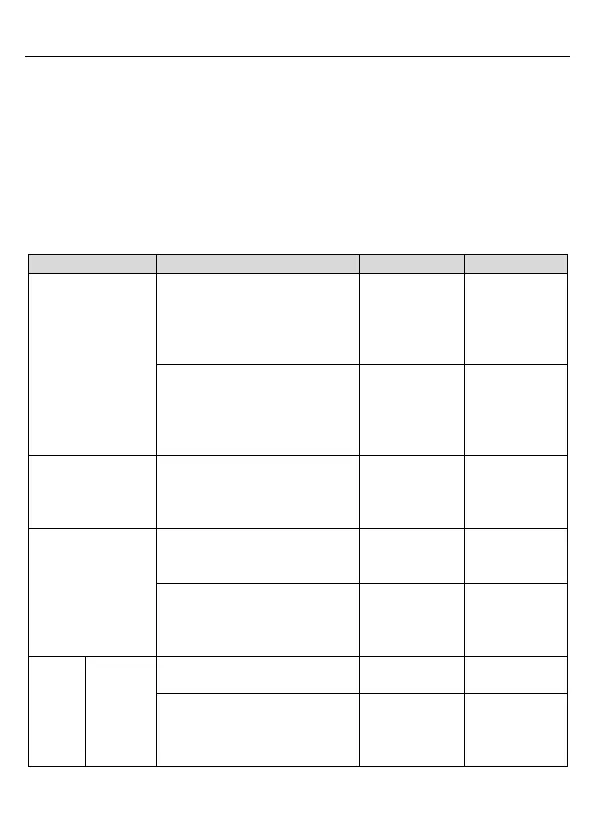

Little maintenance is required when the VFD is installed in the environment that meets

requirements. The following table describes the routine maintenance periods recommended

by INVT.

Check the temperature, and

humidity, and whether there is

vibration, dust, gas, oil spray, and

water droplets in the environment.

Visual

inspection, and

use instruments

for

measurement.

The

requirements

stated in this

manual are met.

Check whether there are foreign

matters, such as tools, or

dangerous substances placed

nearby.

There are no

tools or

dangerous

substances

placed nearby.

Check the voltage of the main

circuit and control circuit.

Use multimeters

or other

instruments for

measurement.

The

requirements

stated in this

manual are met.

Check the display of information.

The characters

are displayed

properly.

Check whether characters are not

completely displayed.

The

requirements

stated in this

manual are met.

Check whether the bolts loose or

come off.

Check whether the machine is

deformed, cracked, or damaged,

or their color changes due to

overheating and aging.

Loading...

Loading...