Goodrive300 Series VFD Communication protocol

214

high bit is in the front and the low bit is in the behind.

"Data number" means the reading data number with the unit of word. If the "start address’ is 0004H

and the "data number" is 0002H, the data of 0004H and 0005H will be read.

CRC occupies 2 bytes with the fact that the high bit is in the front and the low bit is in the behind.

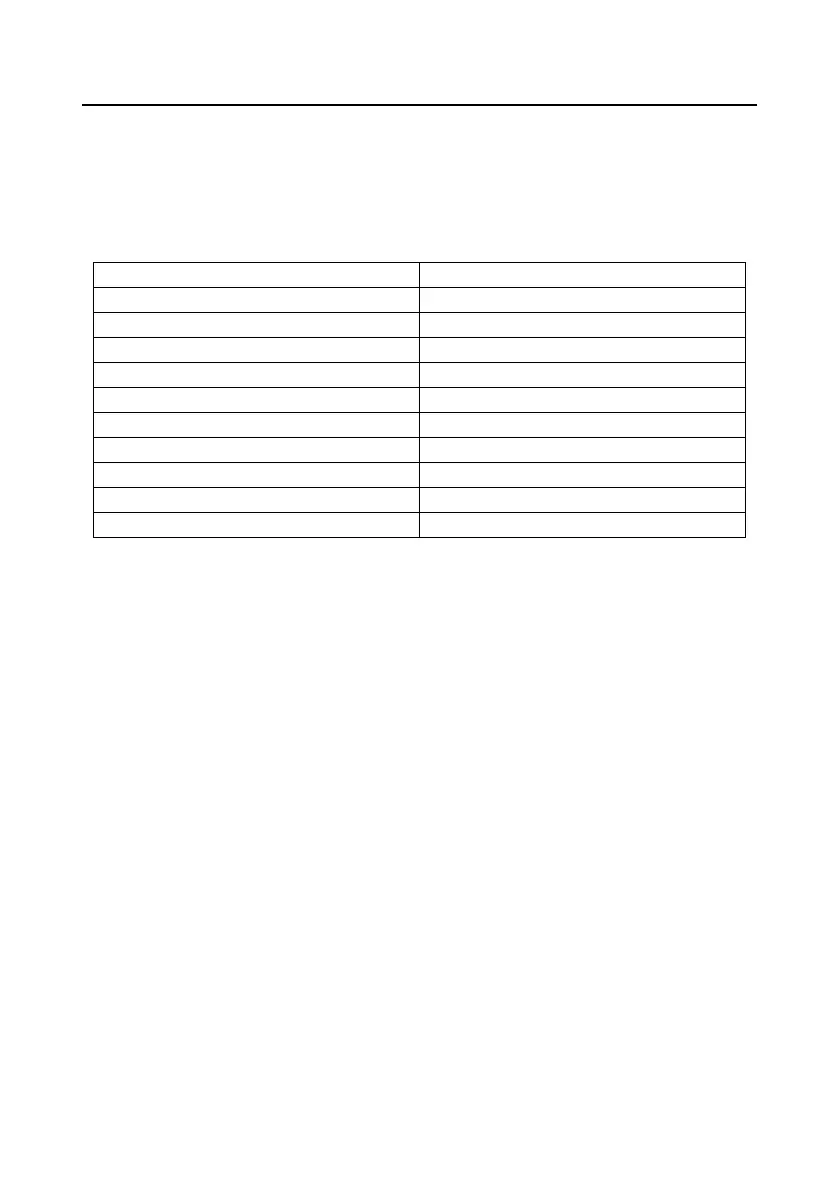

RTU slave response message (from the VFD to the master)

T1-T2-T3-T4 (transmission time of 3.5 bytes)

Data high bit of address 0004H

Data low bit of address 0004H

Data high bit of address 0005H

Data low bit of address 0005H

T1-T2-T3-T4 (transmission time of 3.5 bytes)

The meaning of the response is that:

ADDR = 01H means the command message is sent to the VFD with the address of 01H and ADDR

occupies one byte

CMD=03H means the message is receiced from the VFD to the master for the response of reading

command and CMD occupies one byte

"Byte number" means all byte number from the byte (excluding the byte) to CRC byte (excluding the

byte). 04 means there are 4 byte of data from the "byte number" to "CRC CHK low bit", which are

"digital address 0004H high bit", "digital address 0004H low bit", "digital address 0005H high bit" and

"digital address 0005H low bit".

There are 2 bytes stored in one data with the fact that the high bit is in the front and the low bit is in the

behind of the message, the data of data address 0004H is 1388H,and the data of data address

0005H is 0000H.

CRC occupies 2 bytes with the fact that the high bit is in the front and the low bit is in the behind.

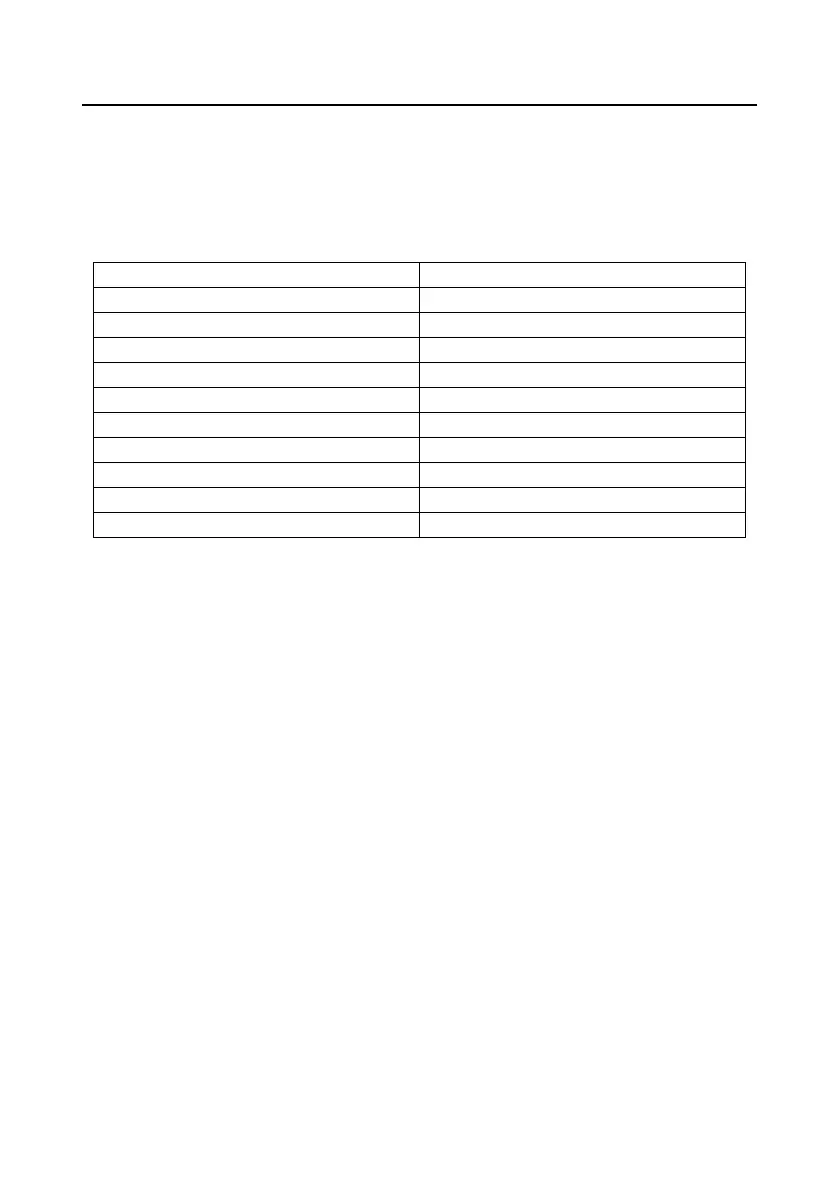

10.4.2 Command code: 06H

06H (correspond to binary 0000 0110), write one word (Word)

The command means that the master write data to the VFD and one command can write one data

other than multiple dates. The effect is to change the working mode of the VFD.

For example, write 5000 (1388H) to 0004H from the VFD with the address of 02H, the frame structure

is as below:

Loading...

Loading...