34

Flow Sensor (Sold Separately)

Flow monitoring is one of the best water resource management tools available in the irrigation industry today. With

denable over and critical ow values, broken lateral or mainline piping, stuck valves and damaged sprinklers can be

quickly detected and bypassed automatically.

The ow sensing capability of the MC-E allows it to learn actual ow rates for every station. These ow rates are stored

in the memory for comparison use. Whenever a station is activated, MC-E will monitor and compare the values to detect

if overow or critical ow values have been violated. The overow percentages are user dened to ne tune the system.

The MC-E is designed to function with a normally open master valve and a ow sensor. The Data Industrial PVC tee

ow sensor model 228PV, 250BR or equivalent are the recommended sensors for use. When MC-E detects a ow value

that violates the station ow parameters, the ow alert LED indicator will illuminate. The MC-E will make an audible

beep every 30 seconds to notify you of the ow error. The controller will also display the problem station on the LCD.

The ow alert indicators will continue until the detected ow is returned within the set parameters and the button is

pressed.

Flow sensing requires that Station 1 is used for a normally-open master valve rather than a

regular station. See Optional Setup.

Flow Sensor Installation

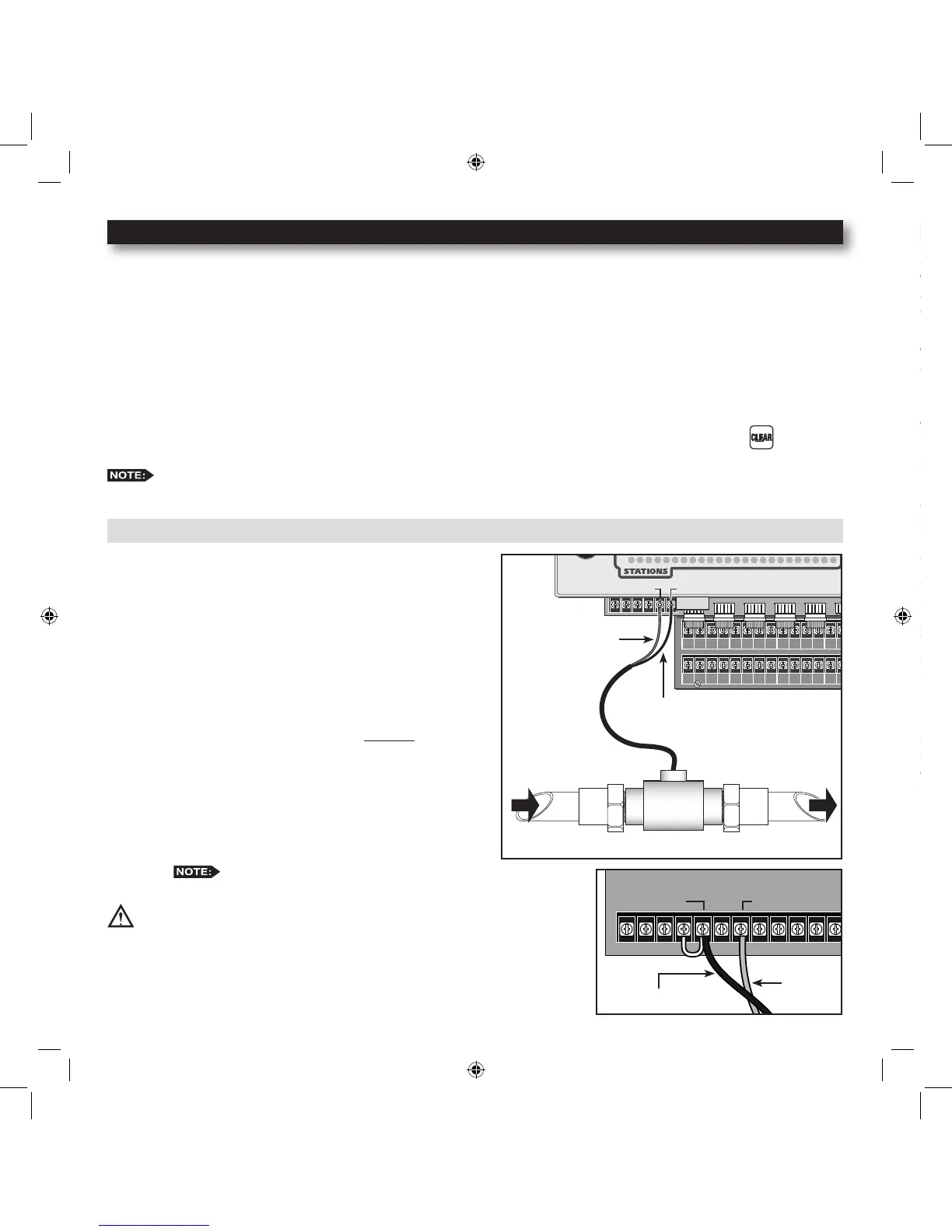

Step 1 – Install the ow meter into the main pipe that only

supplies irrigation to the area being monitored.

Typically, it is installed just before or after the

master valve. Install the ow sensor according to

the provided instructions. Pay particular attention to

the ow direction and to the length of straight pipe

required before and after the ow sensor. Take note

of the sensor size and the pulse rating for the MC-E

ow sensor setup.

Step 2 – Route a two-wire irrigation cable from the ow

sensor to the MC-E controller. The cable can be

2000 ft. in length when using a shielded two-

conductor, 20 AWG or larger stranded copper

wire. Leave extra wire length to allow for future

servicing. Take note which wire is installed to the

red sensor wire as well as the black sensor wire.

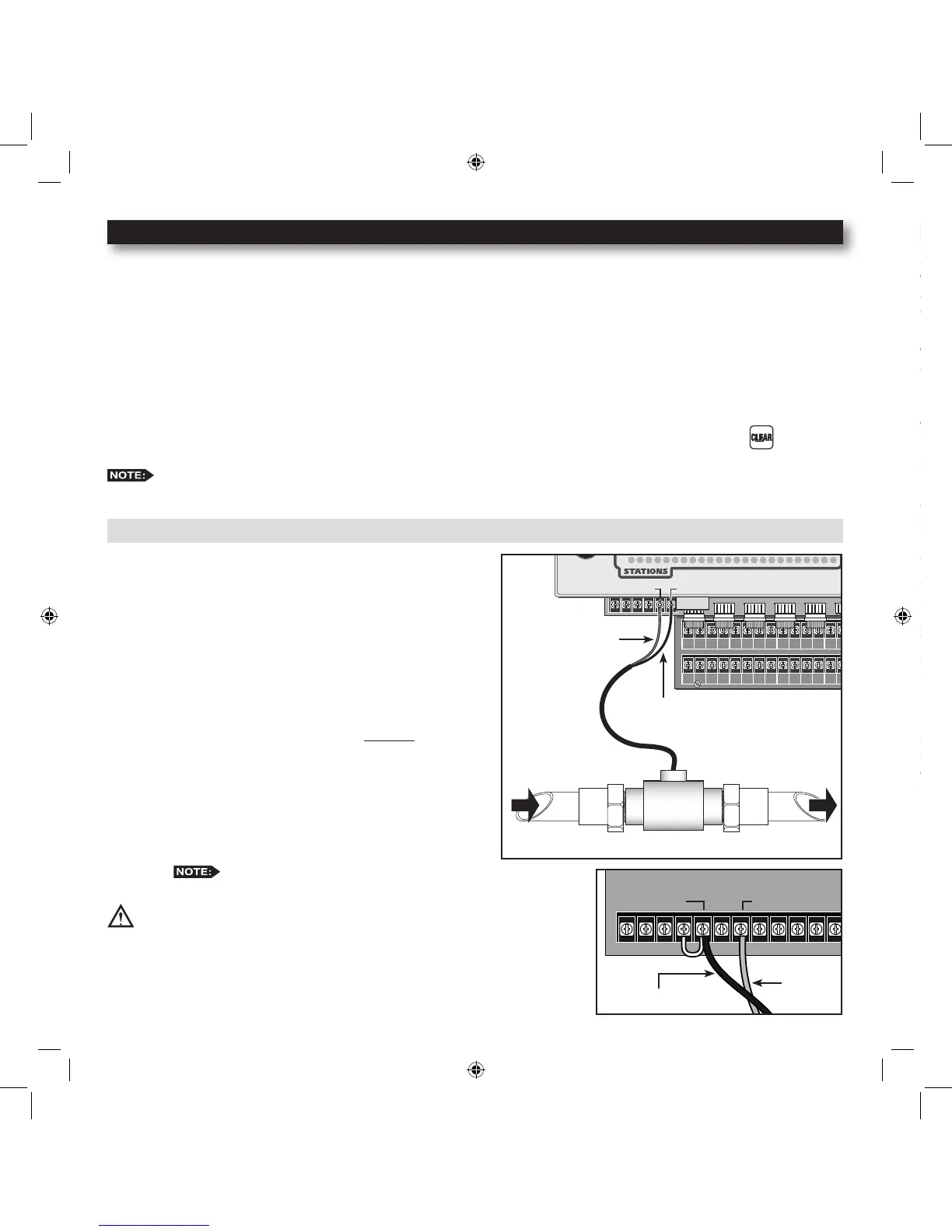

Step 3 – At the controller terminals, connect the “Red” wire

to FLOW+ terminal. Connect the “Black” wire to

the FLOW- or SENSOR- terminal. See illustrations.

The controller will beep every 30 seconds

when an ow error is detected.

IMPORTANT! Sensor wires must be installed in the correct polarity for

proper operation. If you plan to use the controller’s ow sensing function,

set ow parameter and learn the ow value for all the stations being used.

MC-E will not execute the ow diagnostic if an active station is without

ow settings even if other active stations have ow settings congured.

Flow Sensor Setup

Flow Sensor Overview

The ow sensing system in the MC-E is designed to reduce the risk of ood damage and water waste. As previously

described, the controller requires a properly sized ow sensor in the system. Also, (connected to Station #1 which must be

converted to Flow Alarm) a normally-open master valve is required.

In the SETUP procedure all stations must be set to “MV=ON”.

The controller has an adjustable ow delay, with a default length of 1 minute, to allow the ow to “settle” after a valve

opens. After each valve’s delay period, (settable from 1 to 9 minutes) the controller will monitor the sensor reading.

Because of delay times and the length of the automatic ow diagnostic procedure, station times under 3 minutes

are not recommended when using ow sensing.

The controller can “learn” the correct ow for each irrigation zone in the system. Also, the maximum acceptable ow

limit for the main line can also be set. With the above in place, the MC-E can detect an overow condition for a particular

valve in operation (compared to its learned ow) and shut it off. If the controller can cure the ow problem by turning off

the offending station, it will identify the station with the ow error in its display, illuminate the FLOW ALARM light on

its face panel and beep once every 30 seconds to alert the user. Before moving on to the next station in the program, the

controller will check ow in the main line with all valves off. If no ow, the controller moves on. If ow is detected with

no stations on (catastrophic ow), in addition to the alerts above, the controller will energize and close the normally-open

master valve to shut off the irrigation main line.

While the controller is in

AUTO/RUN

, but idle, any detected ow with no valves on will also energize station 1

for shut down. Even if you turn the controller to Rain Off , the MC-E will continue to energize station 1 to keep the

normally-open master valve closed. To clear the ow alert and allow the master valve to open, turn the dial to

FLOW SENSING and press .

Use either STATION TEST or MANUAL to sequence through the stations or to operate a suspect station as you

visually locate the cause of the over ow or unscheduled ow condition. To allow for searching and testing, ow sensing

is not active in STATION TEST or MANUAL modes.

CAUTION:

Flow sensing is active in the controller’s automatic mode for detecting overow conditions in

the remote control valves and mainline catastrophic ow. Other water outlets in the irrigation mainline will cause

unscheduled ow and activate mainline shutdown. To operate quick coupler valves, etc. downstream of the ow sensor,

either disable ow sensing or manually turn on an unused station that has no learned ow. During operation of a station

with no learned ow, ow sensing is disabled.

When the controller is in RAIN OFF

, ow sensing is disabled.

Enable/Disable MC-E Flow Sensing

Step 1 – Place the Function dial to the FLOW SENSING position.

Step 2 – If Flow Sensing is not Enabled, the controller will prompt

“Enable Flow? Press DAYOFF”. Press the button to activate

ow sensing. The K Value/Size Code screen will be displayed when

ow sensing is successfully enabled:

Step 3 – Deactivate ow sensing by pressing the button.

When ow sensing is enabled and activated, station 1 will activate and all other scheduled watering are disabled.

Loading...

Loading...