C.P. SENTINEL AUTOMATIC TYPE CATHODIC PROTECTION RECTIFIER MANUAL

INTEGRATED RECTIFIER TECHNOLOGIES, INC.

Doc #: APC0010

Rev. 3.0, November, 2004

Page 21 of 22

Faulty Connections: Often broken or high resistance connections will lead to no

rectifier output or intermittent output. Disconnect power, check and re-tighten all

connections. Be especially aware of any oxidized, burnt or discoloured

connections. Repair or replace as required.

DC voltage at output lugs, but no current

: The principle reason for this failure is

a broken CP system cables beyond the rectifier. Investigate and repair broken

cables.

DC voltage at output lugs, current flowing to load, but no current reading on

ammeter: This could be the result of a defective ammeter, faulty leads, or

failure of a metering switch. Repair or replace defective components.

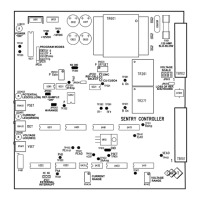

Failure of Reference Electrode

: The SENTRY Controller is equipped with “Loss

of Reference Electrode” shut-down circuitry to prevent coating damage due to

excessive polarization upon failure Reference Electrode. Replace defective

Reference Electrode and re-energize rectifier. Refer to Page 7.

B. LIMITED RECTIFIER OUTPUT CURRENT: This fault may be caused by any one or more

of the following conditions:

Improper Mode settings

on the SENTRY controller resulting in insufficient

current to the CP system. Re-check settings and limits for current, voltage and

potential (If applicable).

Load resistivity too high

for rating of the rectifier. This will usually be indicated

by a “Voltage Limit” condition; where the Red LED is illuminated. Check anodes

and ground bed resistance. Modify if necessary, or replace rectifier with a

higher rated unit.

Low supply voltage

: Check incoming AC voltage to rectifier while rectifier is

under load. Consult electrical maintenance personnel for adjustment if line

voltage is low.

Excessive AC interference

on Reference Electrode to Structure inputs may

reduce the rectifier DC output (on Potential controlled rectifiers). Although

equipped with circuitry to minimize AC interference on the potential measuring

circuit, excessive amounts of interference can cause the SENTRY Controller to

reduce output current or voltage in response to this outside interference.

Review installation practices outlined on Page 7.

Failure of SCR-Diode module

: could result in “half-wave” output, which will yield

only half of the rated output. Replace defective module with replacement.

Failure of the SENTRY Controller board

. Remove defective board & replace

with known working control board.

C. POTENTIAL SET POINT NOT MAINTAINED: This fault may be due to one or more of the

following conditions:

Rectifier output being limited

by either the Voltage Limit or the Current Limit.

Adjust these limits to the maximum rating of the rectifier.

Rectifier output being limited

by the Manual Tap adjustment (On rectifiers

equipped with this option) Sufficient voltage must be supplied from the

transformer taps to maintain the set point potential.

Failure of the Reference Electrode

results in limited or no output. See Page 7.

Excessive AC input on Reference Cell

– Structure leads. See Item “B”, above.

Defective “Press-to-Set” selector switch

. Oxidized contacts could result in the

“Set Potential” not being switched correctly into the SENTRY Controller.

Loading...

Loading...