osition Control

Position control is used when attachin

implements and other operations requirin

the imple-

ment to be kept at a constant hei

round.

It is also used with tool bars havin

lexible row units

and implements equipped with

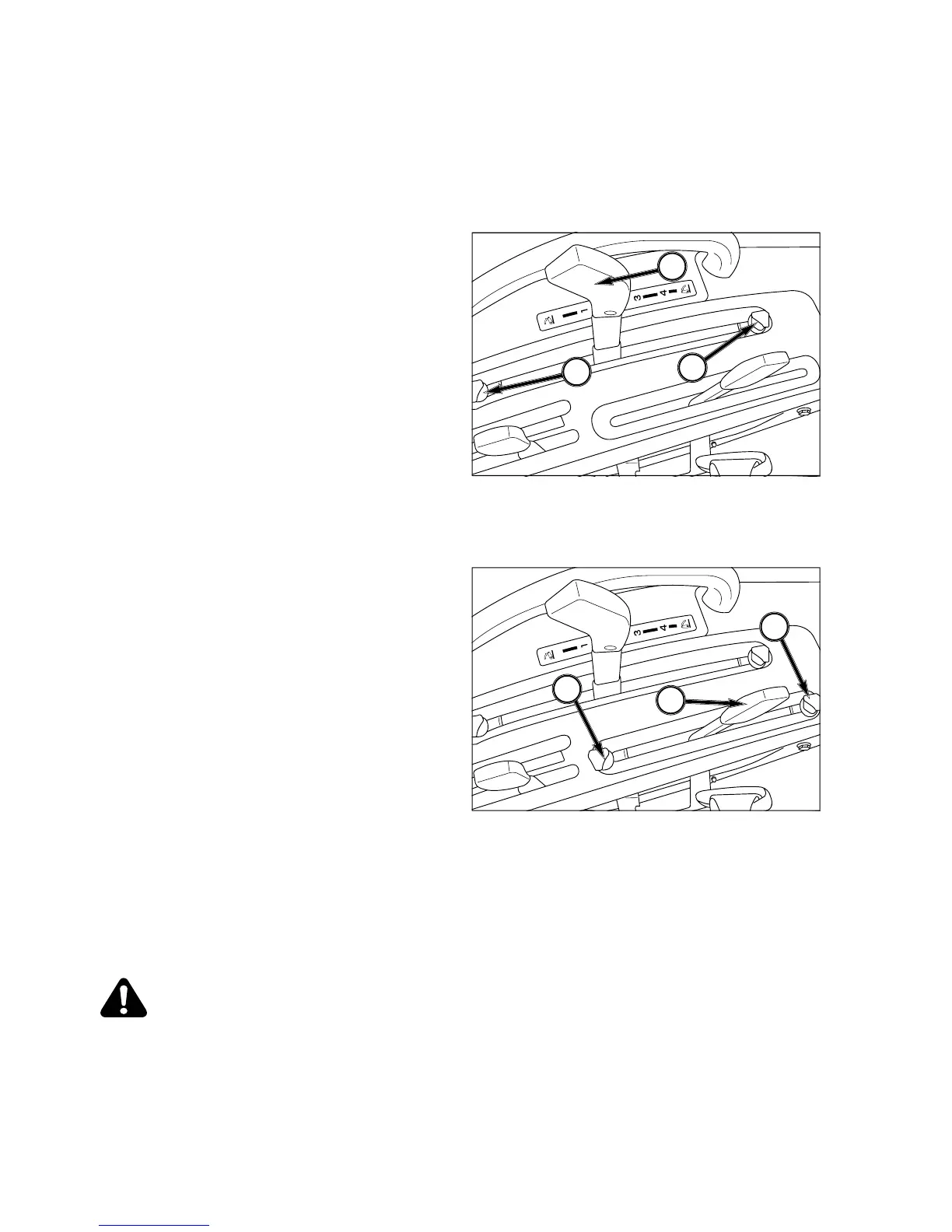

The position control lever maintains hitch

osition at a constant hei

ht in relation to the tractor. As

the position control lever, 1, is moved backward, hitch

and implement are raised. Movin

the lever forward

will lower hitch to selected position. Each lever settin

ic hitch and implement position.

The front lever stop, 2, can be set to contact the posi-

tion control lever in the implement work position. This

nables the implement to be returned to the identical

ter the hitch has been raised

, etc.

The rear lever stop, 3, can be set to limit raisin

ht, if required.

NOTE: When starting engine, ensure implement i

owered to the ground and lever is

orward.

This reduces load on starter due to hitch tr

o raise when engine is cranked.

FIG. 4-41

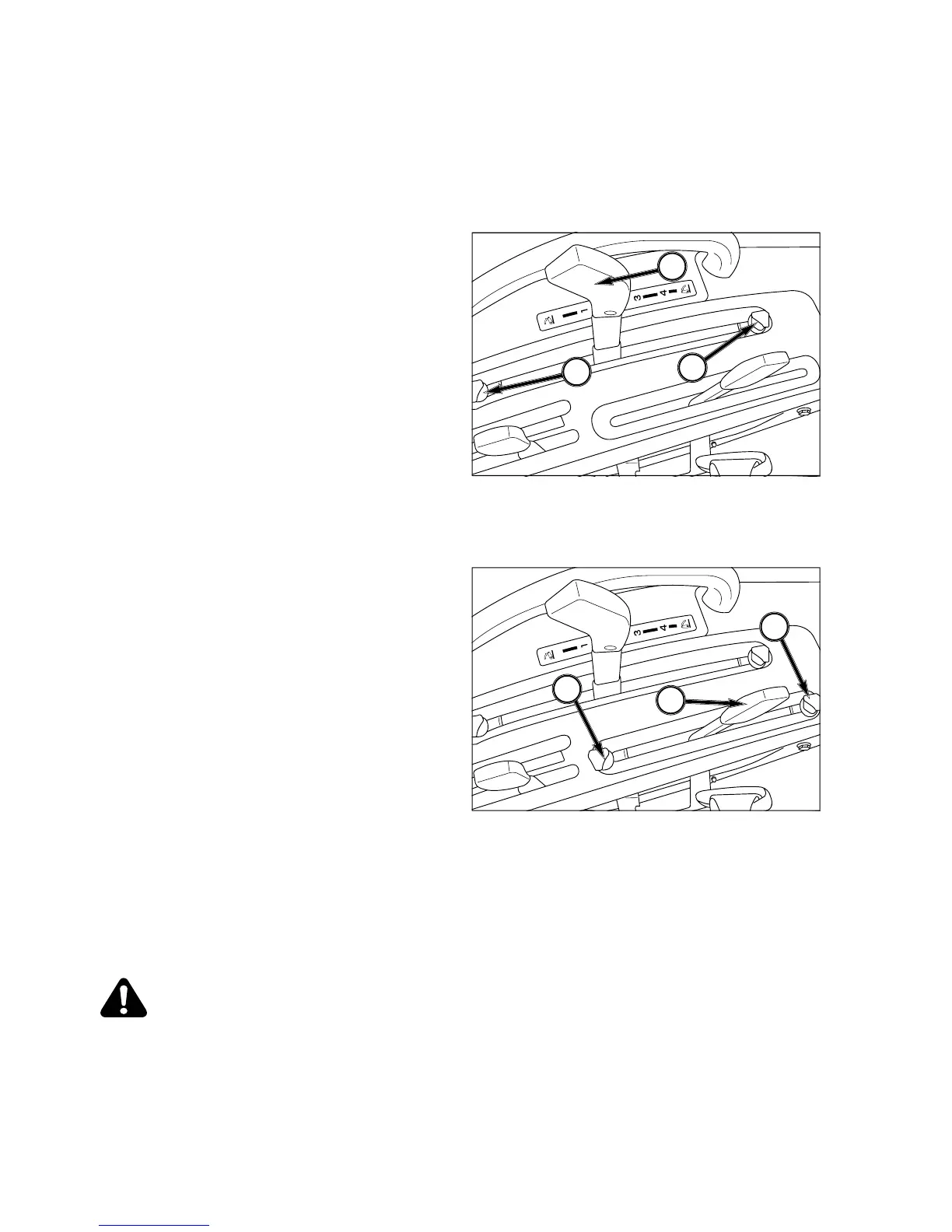

n the tractor and imple-

ment in the field and move the position control lever,

1, forward

the position control lever and set the ad

tops, 2, and 3, as desired.

When turnin

, move position control lever backward

to raise the implement and permit

turn. Return the implement to the work

the position control lever to the

ainst the stop.

To finish work and transport, pull position control lever

to the “draft” or pull of

implements. This provides consistent load

on Tractor and provides wei

ht transfer to Tractor rear

wheels to reduce wheel slippa

e.

Lever stops, 2, and 3, can be ad

osition control lever, 1,

when attachin

NOTE: When starting engine, ensure implement i

owered to the ground and both levers are

ing to raise when engine is cranked.

FIG. 4-40

FIG. 4-4

Loading...

Loading...