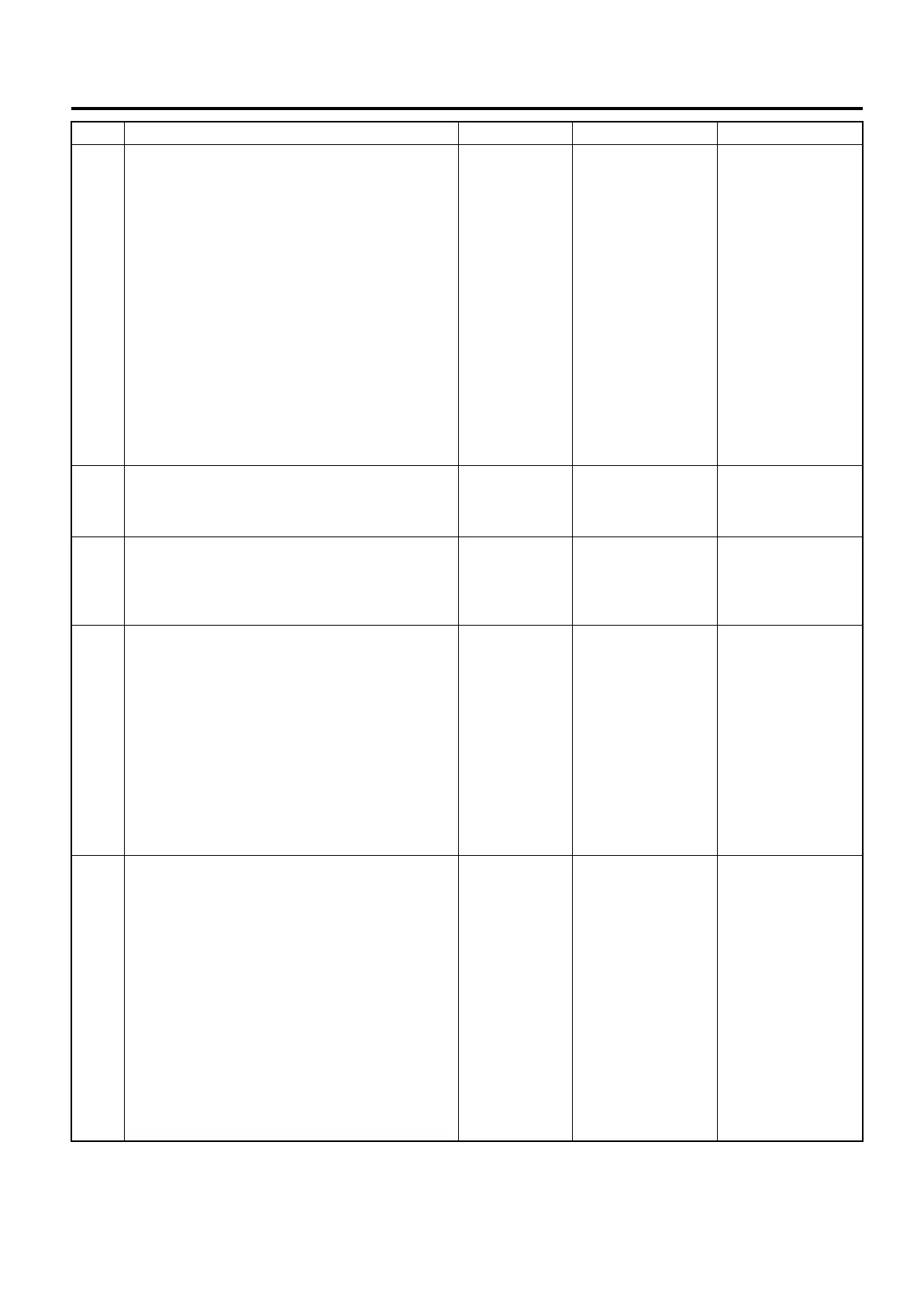

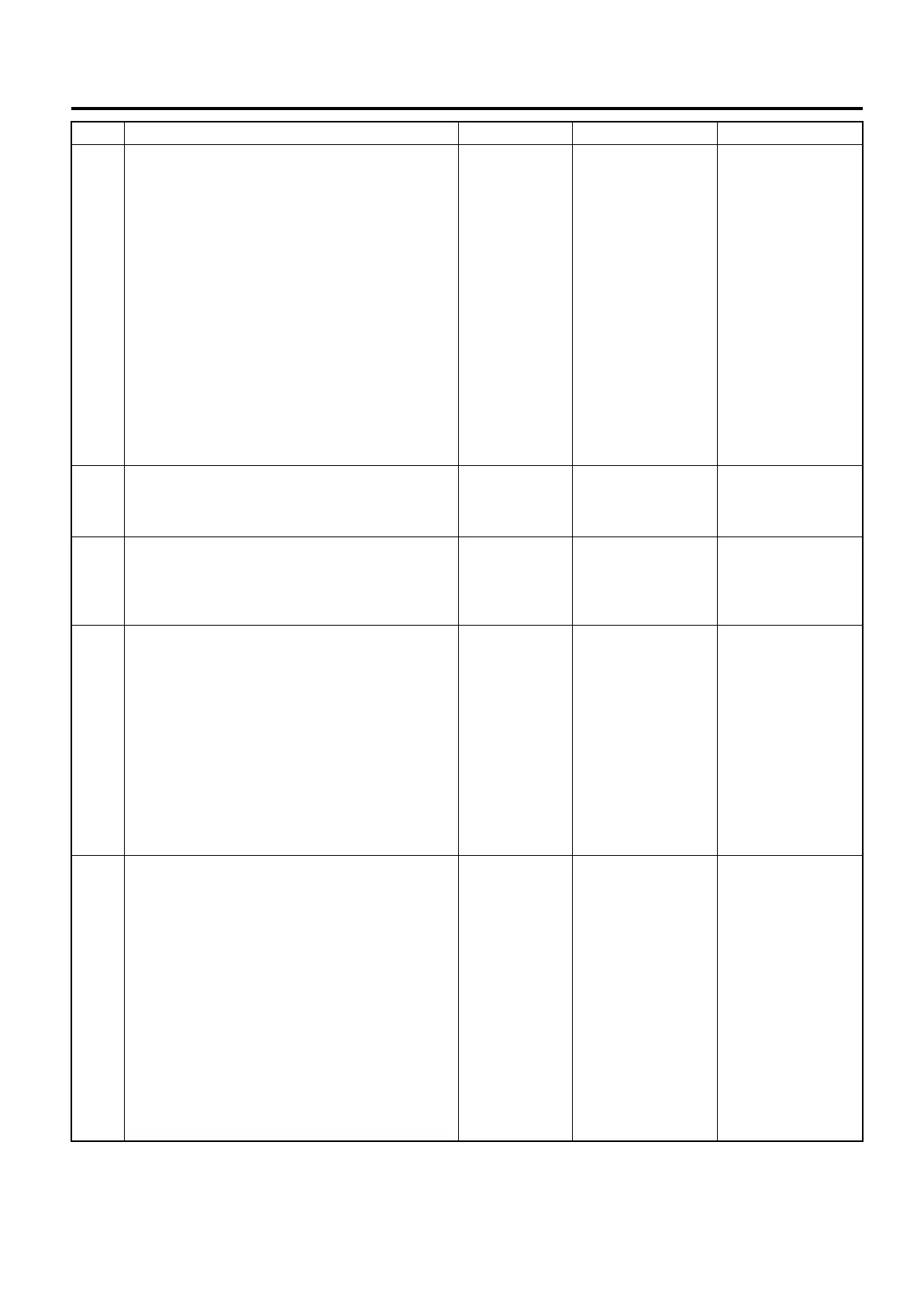

Engine Control System (4HK1) 1A-63

6

1. Turn OFF the ignition.

2. Disconnect the FRP sensor harness

connector.

3. Inspect for an intermittent, for poor

connections and corrosion at the harness

connector of the FRP sensor (pins 1, 2 and 3

of E-19).

4. Disconnect the ECM harness connector.

5. Inspect for an intermittent, for poor

connections and corrosion at the harness

connector of the ECM (pins 82, 87, 90 and

101 of E-12).

6. Test for high resistance on each circuit.

7. Repair the connection(s) or circuit(s) as

necessary.

Did you find and correct the condition?

—

Go to Step 11 Go to Step 7

7

Replace the FRP sensor. Refer to Fuel Pressure

Sensor in Section 1D Engine Fuel.

Did you complete the replacement?

—

Go to Step 11

—

8

Repair the short to ground between the ECM (pins

89 and 97 of E-12) and the FRP regulator (pin 2 of

E-17).

Did you compete the repair?

—

Go to Step 11

—

9

1. Check for normal readings at key up for the

following sensor inputs: Use the Scan Tool

Data List or a known good vehicle to

determine nominal values.

• Engine Coolant Temperature Sensor

• Barometric Pressure (BARO) Sensor

• Boost Pressure Sensor

• Intake Throttle Position Sensor

2. Repair the circuit(s) or replace the sensor as

necessary.

Did you find and correct the condition?

—

Go to Step 11 Go to Step 10

10

1. Other possible causes for the no-start

condition:

• Engine mechanical timing

• Flywheel installed incorrectly causing the

crankshaft position (CKP) sensor to be

incorrectly timed to the engine.

Disconnect sensor and attempt to start

engine to verify.

• Heavily restricted intake or exhaust

plugged solid.

• Poor engine compression.

• Water or gasoline contamination in fuel.

2. Repair as necessary.

Did you find and correct the condition?

—

Go to Step 11

—

Step Action Value(s) Yes No

LG4HKED-WE-0871.book 63 ページ 2007年11月29日 木曜日 午後6時29分

Loading...

Loading...