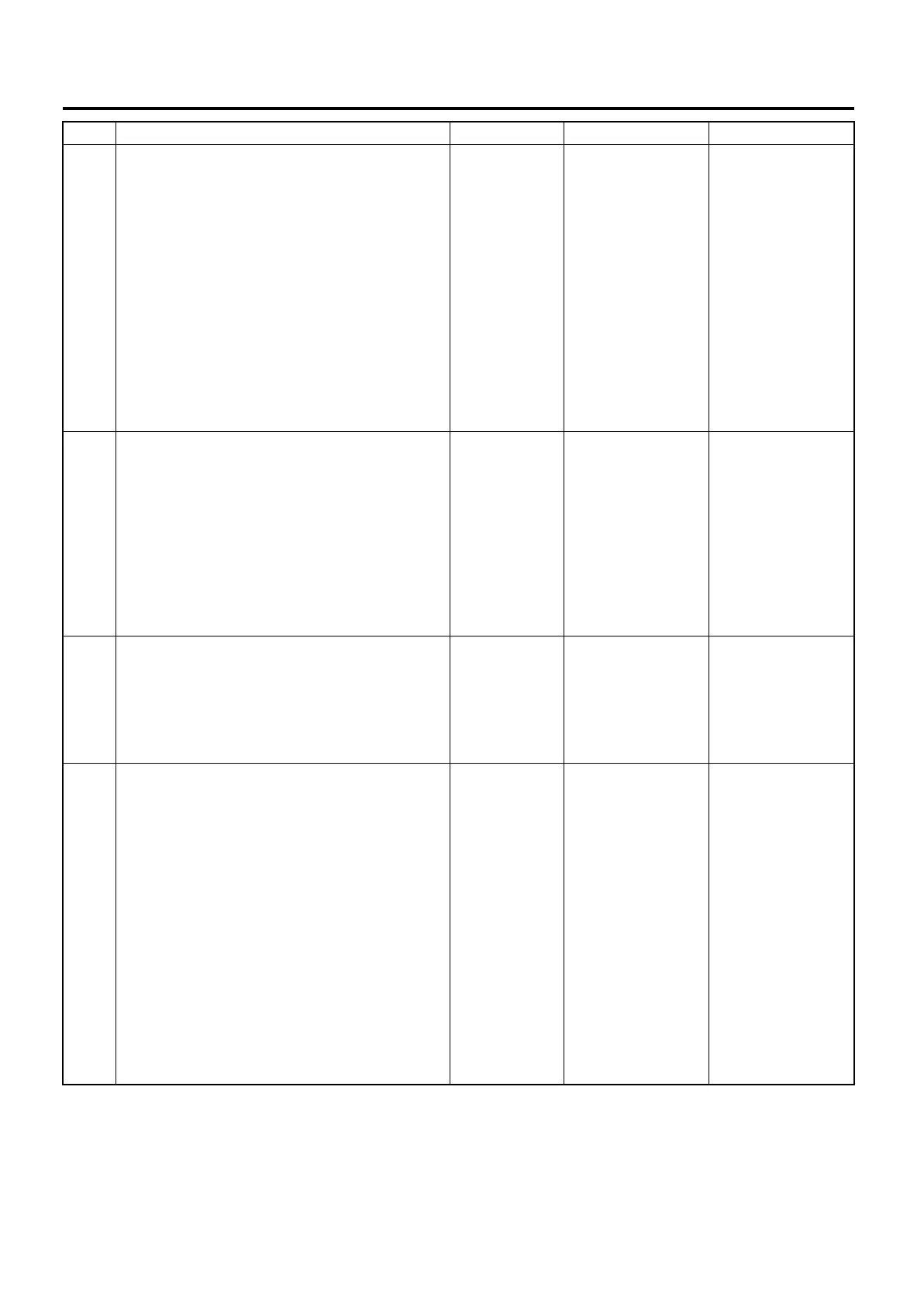

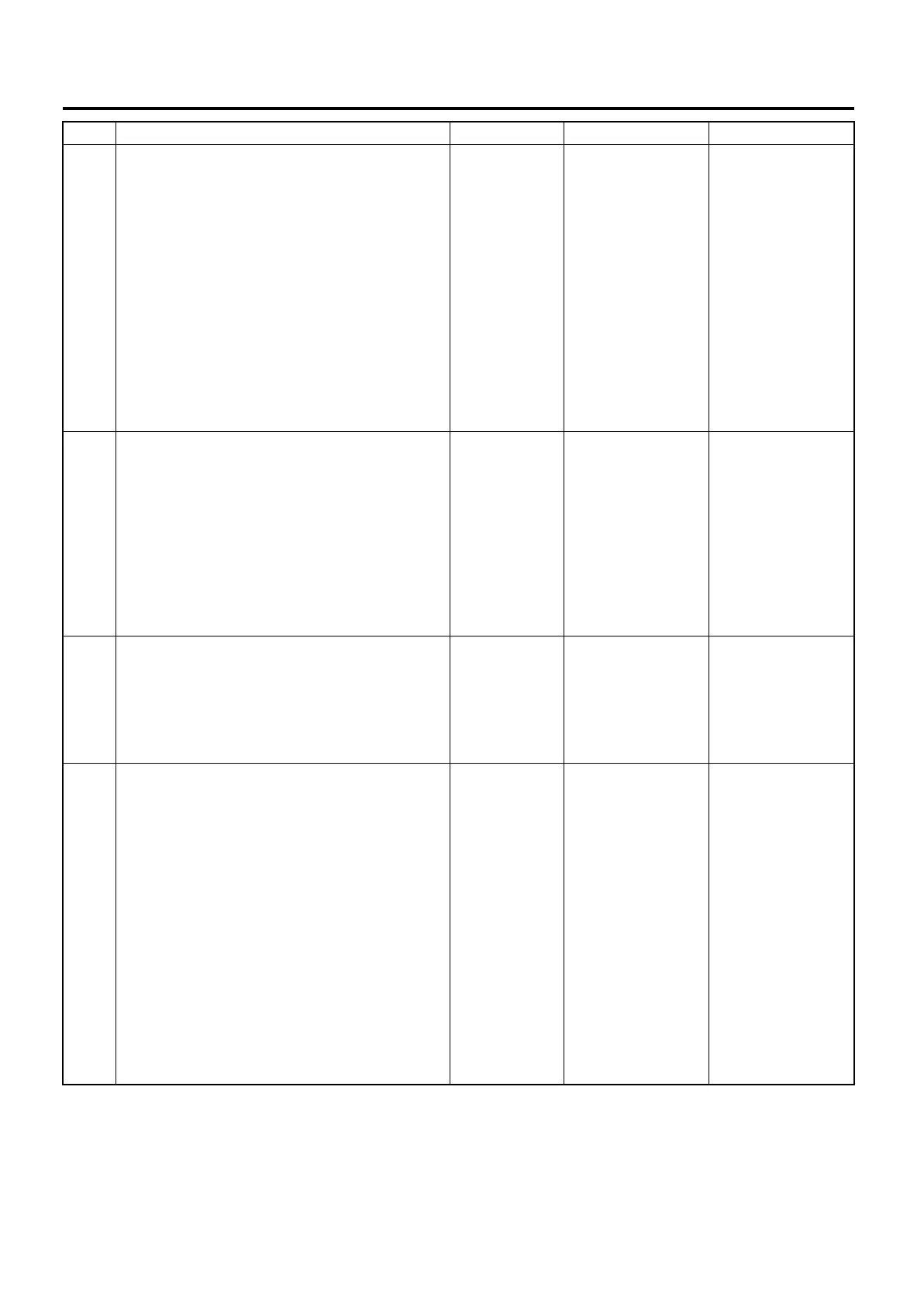

1A-82 Engine Control System (4HK1)

8

1. Fully clamp off a fuel hose as close to the fuel

tank as possible (this will draw vacuum on the

fuel system). You can also disconnect a fuel

line and plug it.

2. Start the engine and turn the idle up control

knob to the highest position. (Full clockwise

direction. The idle speed is increased up to

1600 RPM.)

3. Monitor the fuel pressure/ vacuum gauge.

Notice: Release the clamp or open the plug

when the gauge is likely to be more than 8

inHg during the test.

Can a vacuum of at least the specified amount

be pulled on the fuel system?

8 inHg

Go to Step 11 Go to Step 10

9

1. Inspect the fuel lines between the fuel supply

pump and fuel tank for being crushed or

kinked.

2. Inspect for a plugged fuel tank vent hose.

3. Inspect inside the fuel tank (if possible) for any

foreign material that may be getting drawn into

the fuel line pickup causing a blocked

condition.

4. Repair or replace as necessary.

Did you find and correct the condition?

—

Go to Step 17 Go to Step 13

10

1. Inspect the fuel system line connections

between the fuel tank and the fuel supply

pump for tightness and all fuel hoses for cuts,

cracks and for the use of proper clamps.

2. Repair or replace as necessary.

Did you find and correct the condition?

—

Go to Step 17 Go to Step 11

11

1. Turn OFF the ignition.

2. Disconnect the FRP regulator harness

connector.

3. Inspect for an intermittent, for poor

connections and corrosion at the harness

connector of the FRP regulator (pins 1 and 2

of E-17).

4. Disconnect the ECM harness connector.

5. Inspect for an intermittent, for poor

connections and corrosion at the harness

connector of the ECM (pins 89, 97, 105 and

113 of E-12).

6. Test for high resistance on each circuit.

7. Repair the connection(s) or circuit(s) as

necessary.

Did you find and correct the condition?

—

Go to Step 17 Go to Step 16

Step Action Value(s) Yes No

LG4HKED-WE-0871.book 82 ページ 2007年11月29日 木曜日 午後6時29分

Loading...

Loading...