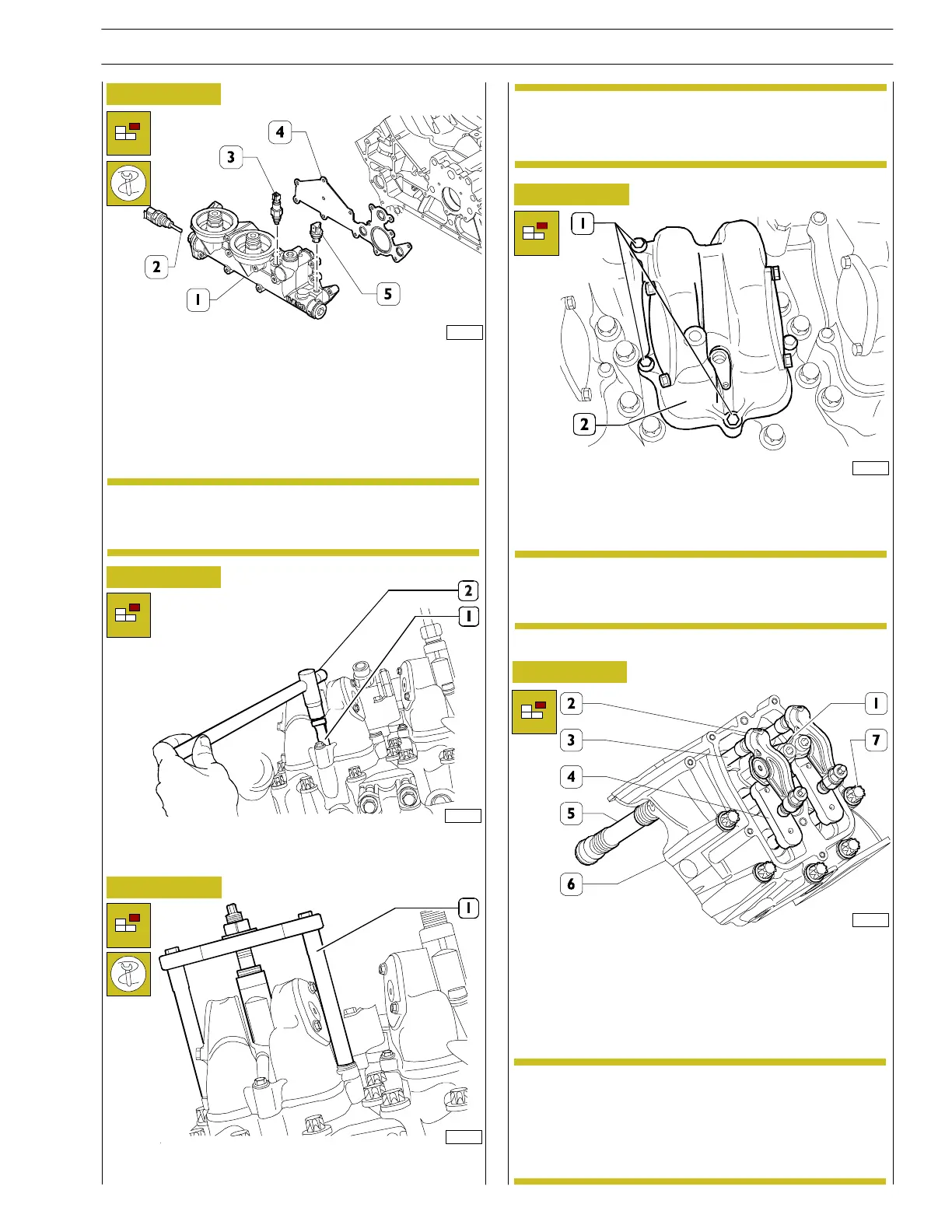

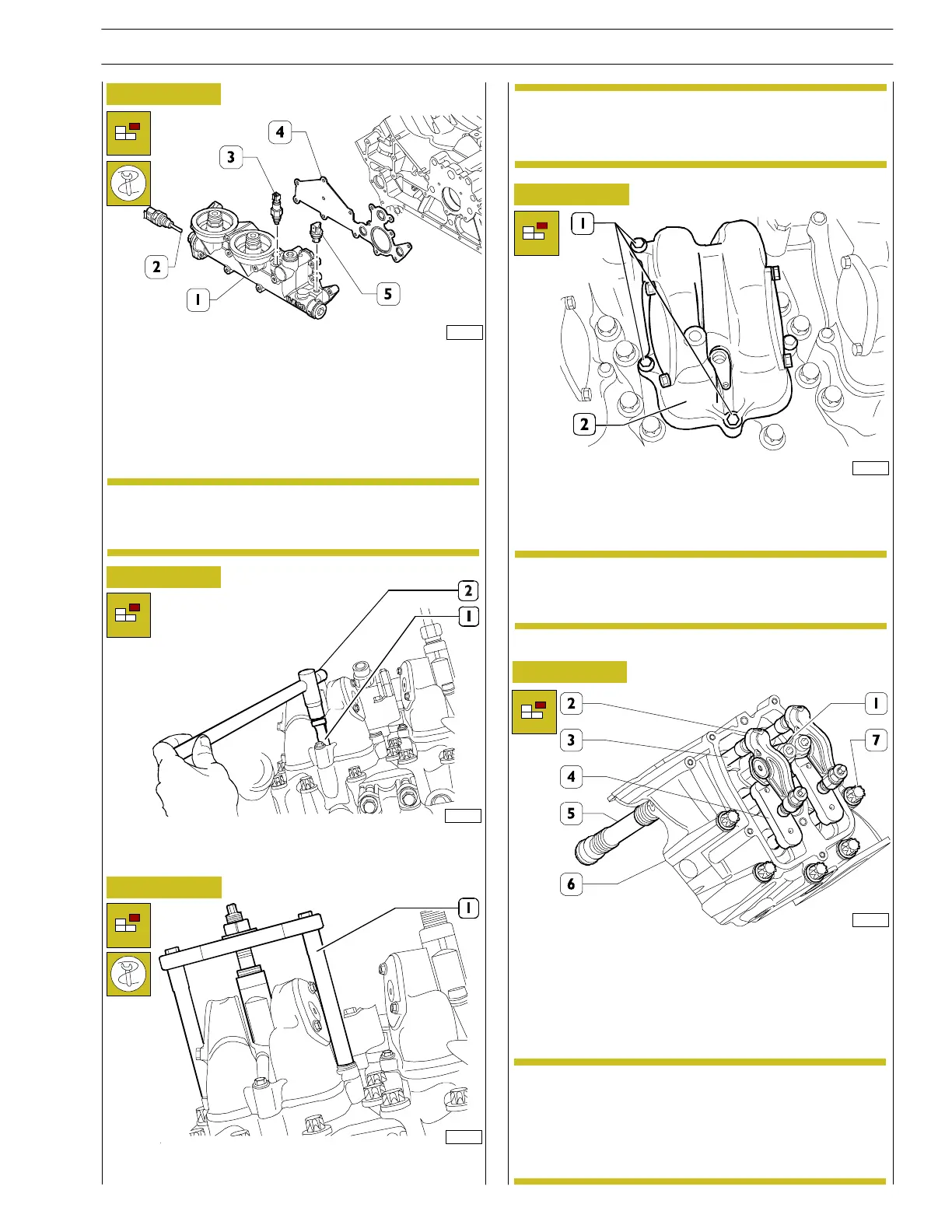

Figure 26

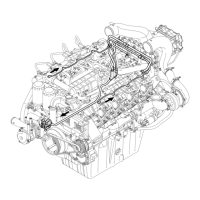

Figure 27

Figure 28

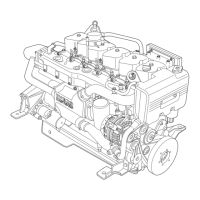

Figure 29

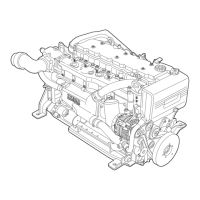

Figure 30

- From the front side disassemble the engine oil filter

supports (1) including the oil temperature transmitters

(2), the pressure sensor (5), the seal (4) and t he filter clog

sensor (3).

- Remove the remaining diesel pipe from the LPP to the

filter mounting (the two components have already been

removed previously)

- Remove the electro—injectors. Using the wrench (2),

unscrew the screw (1) of the fixing bracket.

- Fit the tool 99368505 (1) and the wrench for extracting

the electro—injector.

- Unscrew the fixin g screws (1) and remove the t appet

cover (2). Repeat this operation for all the covers.

- Remove the rocker arms (2) from the support (1), taking

out the circlips and seals on both sides of the support.

Extract the rods (3) from their seat on the heads and the

jumpers (4).

- Unscrew the fixing screw s (7) and remove the head (6).

Remove the cases (5) protectin g the valves.

Always chan ge the O—ring in t he assembly phase.

Lubricate the O-rings with vaseline before

installating

82216

82220

82218

82217

82219

NOTE

If necessary, replace the worn parts. Always change

the seals in the assembly phase.

NOTE

NOTE

Note down the position of the tappet covers in

relation to the heads so as to fit them in the

positions they had with th e first assembly.

The screws (7) fixing the head on the crankcase

have different sizes:

M15x170

M15x185

Mark them so as to facilitate the assembly phase.

NOTE

SECTION 3 - INDUSTRIAL APPLICATION

19

VECTOR 8 ENGINES

Print P2D32V001E Base - April 2006

Loading...

Loading...