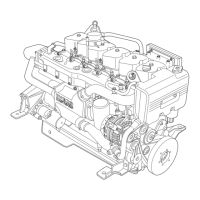

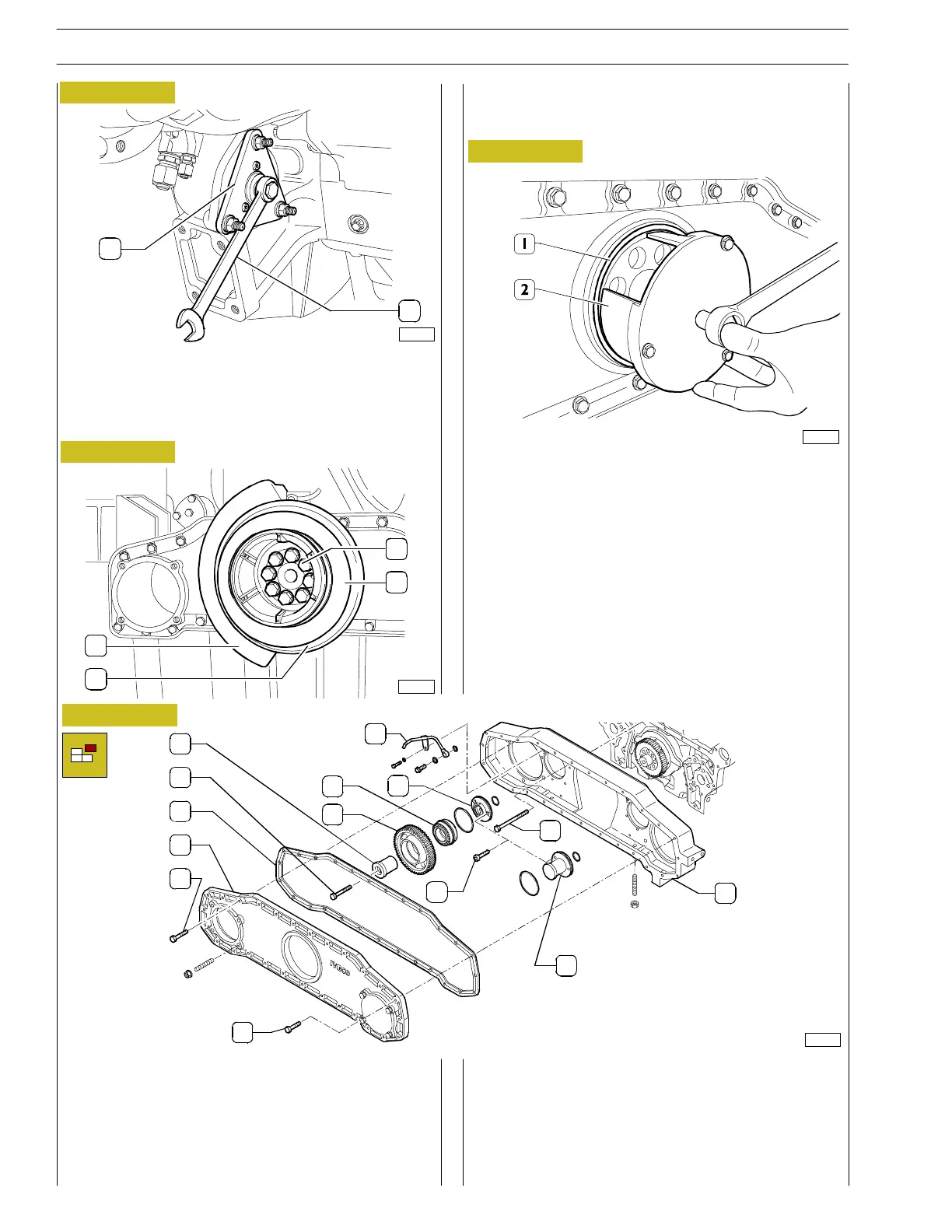

- Undo the M8 bolts (1) and remove the cover (2) for the

gear casing. Remove the gasket (3).

- Remove the duct (12).

- Unscrew th e screw (4), remove the shaft (5) and the

gear (6) with the bearing (7).

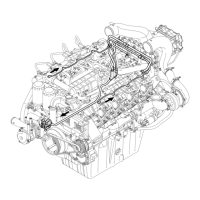

- Remove t he oil seal (1) using the tool 99368514 (2).

- Rotate the engine and remove the oil sump.

- Remove the engine lubricating oil pump with the suction

cup.

- Undo the bolt (10) securing the gear casing (11) to the

cylinder block/crank case; after having removed t he gear

casing, undo the bolt (9) and remove the spacers (8) and

(13) complete with O-rings.

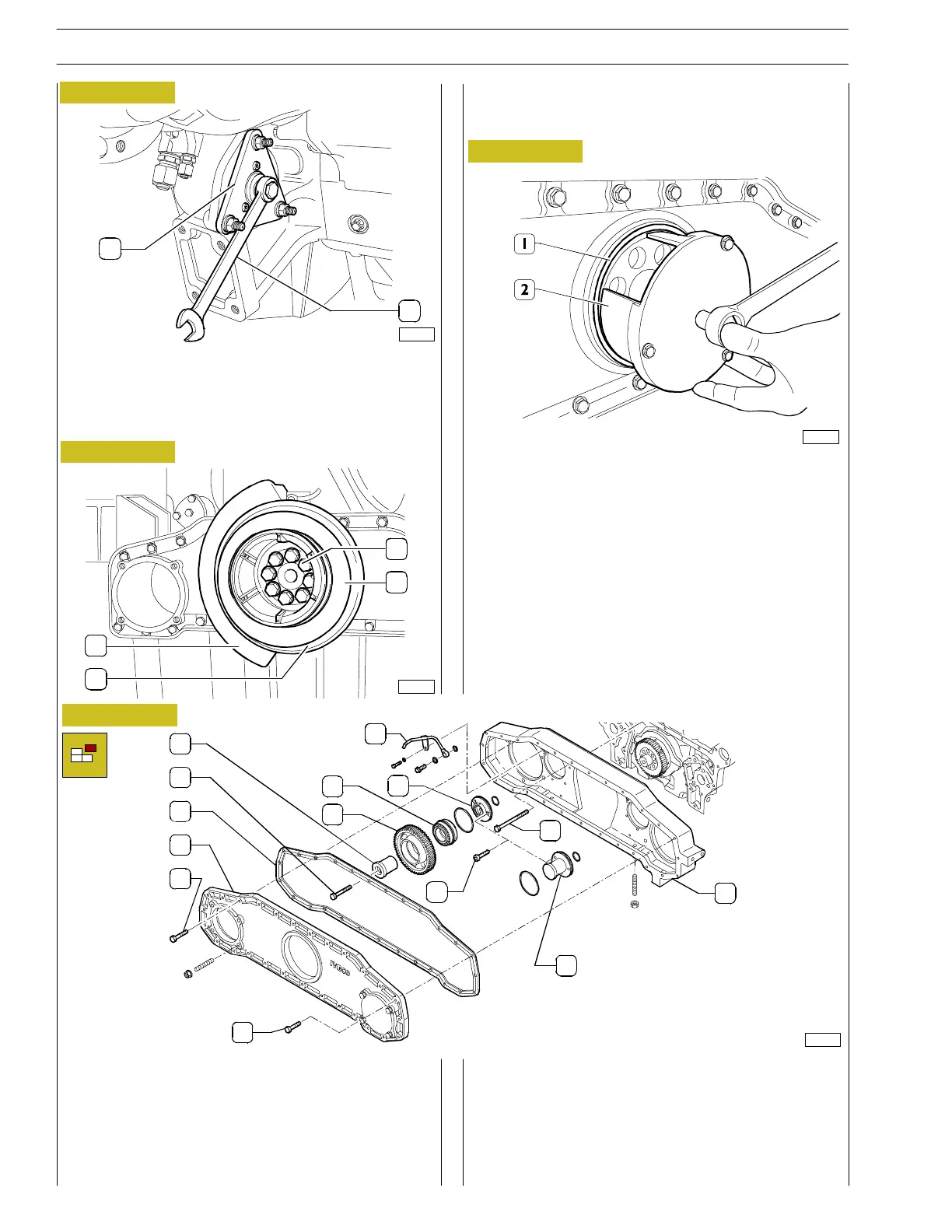

- Fit tool 99368502 (1) and place th e fixed spanner (2) as

shown in the diagram to prevent the rotation of the

flywheel during the dismantling of the pulley and the

damper flywheel on one side and the actual flywheel on

the other.

Figure 31

Figure 32

Figure 33

- At the front, undo the 8 botls (1) and remov e the pulle y

(2), the damper flywheel (3) and the counter-weight (4).

Figure 34

103191

82223

103192

2

1

1

2

4

3

103193

1

1

2

3

4

6

78

5

12

13

9

10

1

1

20

SECTION 3 - INDUSTRIAL APPLICATION

VECTOR 8 ENGINES

Base - April 2006 Print P2D32V001E

Loading...

Loading...