Do you have a question about the Ivoclar Vivadent Programat CS and is the answer not in the manual?

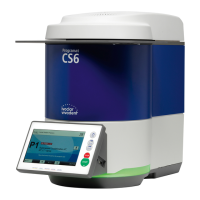

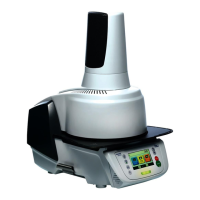

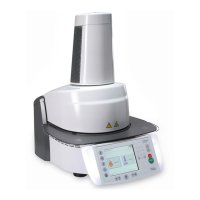

Introduction to the Programat CS furnace and its purpose in dental practice.

Explanation of symbols used in instructions for important points and warnings.

Information regarding different voltage versions available for the furnace.

Specifies that the Programat CS is for dental ceramic material firing only.

Lists actions to avoid to prevent damage or injury, such as carrying by cables.

Details further contraindications like not using without a firing table or inserting foreign objects.

Warns about burn hazards from hot surfaces and crushing risks from moving parts.

Covers voltage, power, placement, air vents, and cleaning precautions.

Addresses ceramic fibres, dust hazards, and disposal requirements.

Lists the main components of the Programat CS furnace.

Identifies risk areas and associated safety equipment for the furnace.

Describes the furnace's functional capabilities and available accessories.

Specifies the intended use and limitations of the Programat CS furnace.

Instructions for unpacking the furnace and checking for completeness.

Guidance on choosing a suitable location and initial assembly steps.

Step-by-step guide for installing the cooling tray onto the furnace.

Instructions for correctly placing the firing plate onto its holder.

Procedure for correctly mounting the furnace head onto the base unit.

Details on connecting the thermocouple and heater plugs.

Steps for securing the heater plug and attaching the furnace hood.

Guide for connecting the power cord and vacuum pump.

Step-by-step instructions for safely removing the furnace head.

Procedures for connecting power and initiating the furnace's initial self-test.

Basic overview of operating the Programat CS via its graphical display and keys.

Detailed explanation of each button and its function on the control unit.

Interpretation of information displayed on the furnace screen during operation.

Describes the three types of programs: standard, free, and test programs.

Lists and defines parameters that can be adjusted for firing programs.

Visual examples illustrating typical glaze and crystallization firing curves.

How to adjust display contrast and temperature units (°C/°F).

Configuration options for language selection, audio volume, and beeper tunes.

Options for programming parameters and conducting temperature calibration.

Enables or disables the "Ivoclar Vivadent optimized temperature control function".

Resetting parameters to factory defaults and importance of user code.

Accessing serial number, software version, and operating hours.

Explains the meaning of various symbols shown on the furnace display.

Describes the different beeper signals and their significance.

Step-by-step guide for powering on/off and entering stand-by mode.

Procedures for executing pre-set and custom firing programs.

Explains general write protection and how to stop/continue running programs.

Guide to setting parameters for single-stage firing programs.

Instructions for configuring multi-stage firing programs with stage switching.

Regular checks and maintenance tasks for optimal furnace performance.

Guidelines for cleaning various parts of the furnace.

Explains vacuum pump, heating muffle, keypad, and cleaning test programs.

Step-by-step guide for calibrating the furnace temperature using the ATK 2 set.

Recommendations for stand-by mode and dehumidification program usage.

Lists and explains various error codes and their meanings.

Describes how the furnace reacts to different error conditions.

Provides a comprehensive list of other error messages requiring contact with service.

Lists common issues that may occur without error messages and their checks.

Guidelines for authorized repairs and warranty expiration.

Lists standard delivery contents and technical specifications of the furnace.

Specifies acceptable ambient temperature, humidity, and pressure ranges.

Provides recommendations for transporting and storing the furnace.

Information on obtaining and using program tables for the furnace.

Overview of the structure of different programs available for the furnace.

| Display | LCD |

|---|---|

| Category | Dental Equipment |

| Application | Ceramic firing, sintering, pressing |

| Connectivity | USB |

| Power Supply | 220-240V, 50/60Hz |