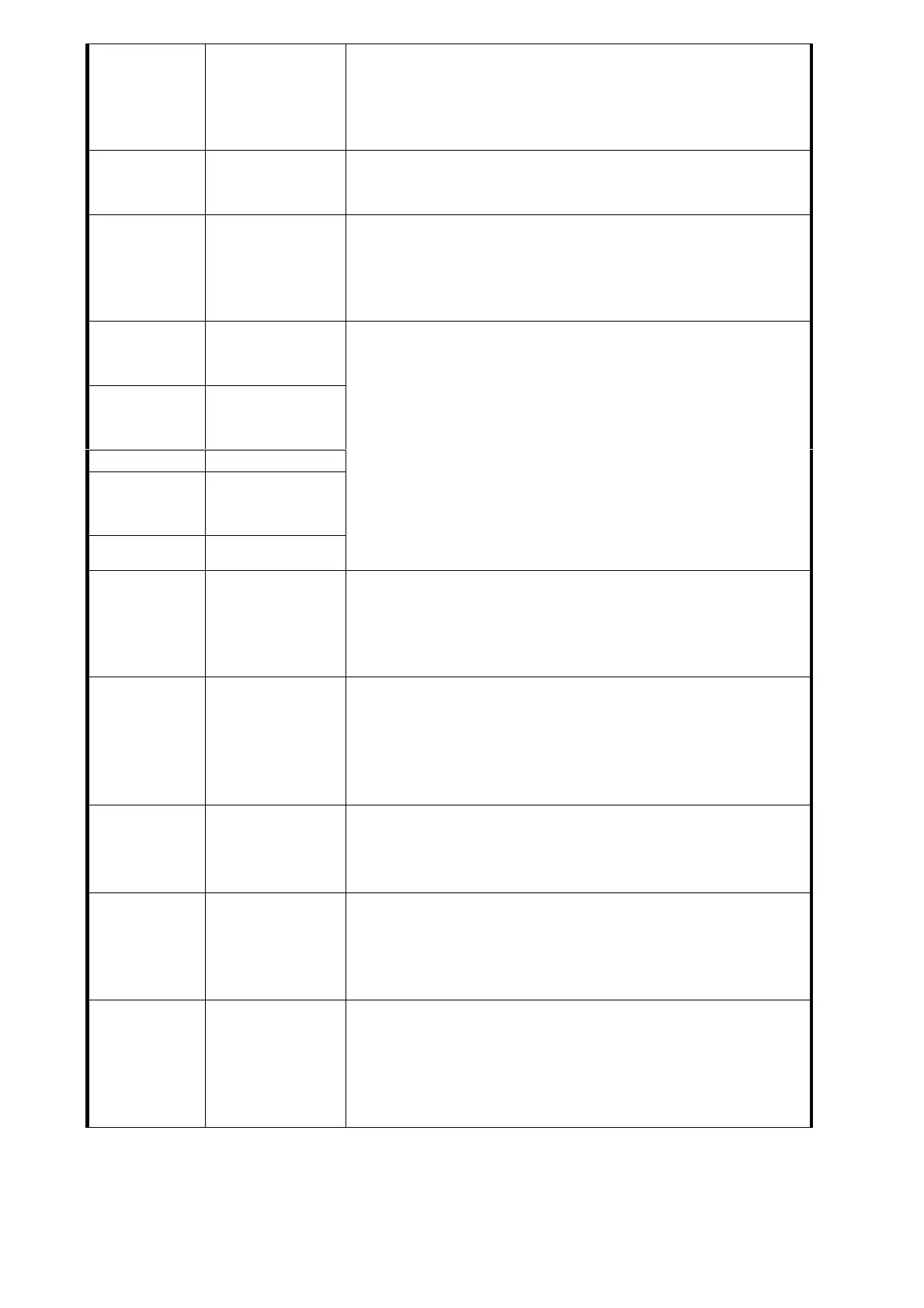

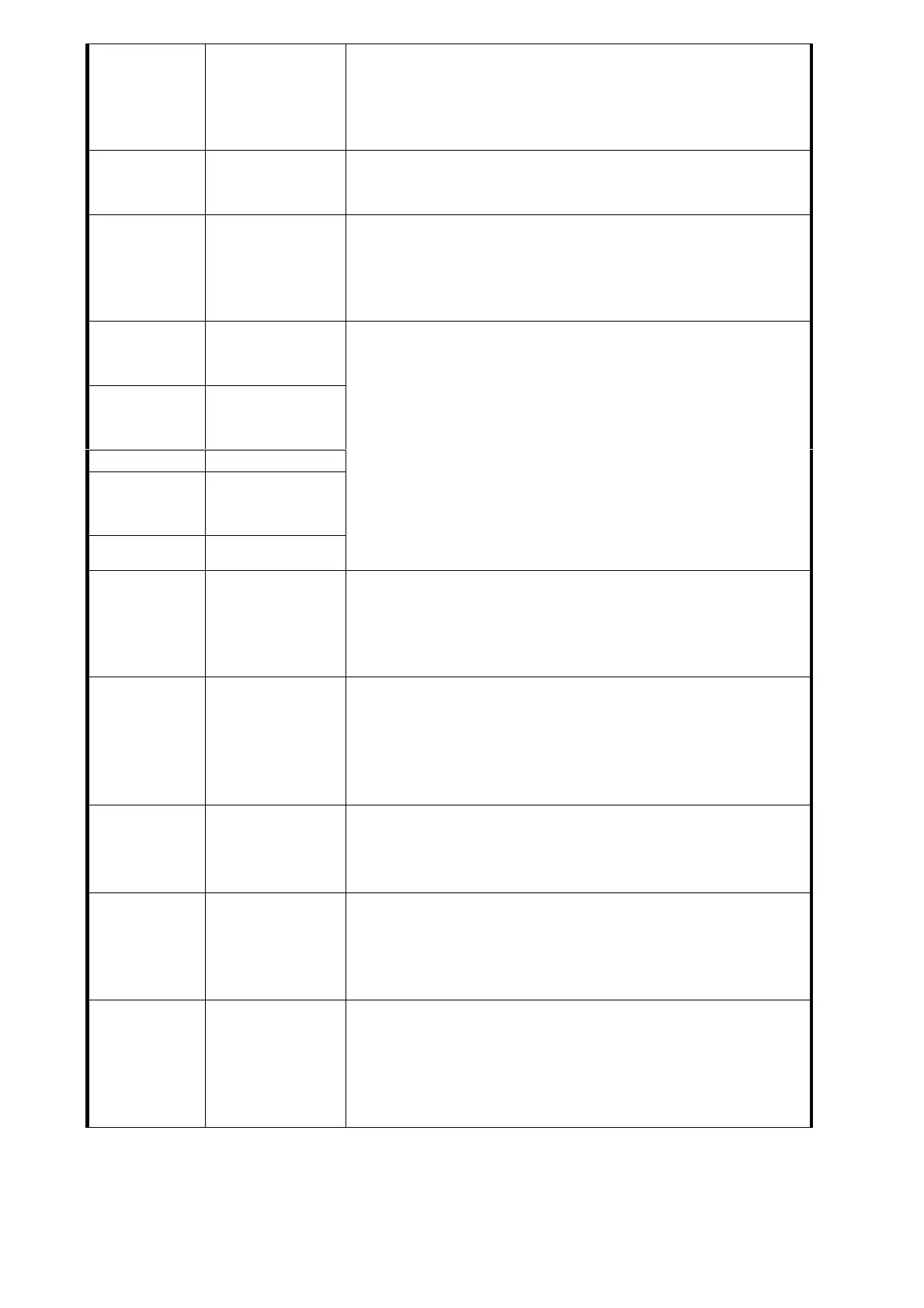

The nose needle

Signal failure

Check whether the nose synchronous signal device and

the connection to the controller is loose, it returned

to normal after restart the system. If it still

doesn't work, please replace the controller and notify

the manufacturer.

Motor fault

initial Angle

measure

Please try again when the power is 2-3 times, if still

at fault, please replace the controller and notify the

manufacturer

Shut down the system power supply, check that the

motor sensor connector is loose or fall off, it

returned to normal after restart the system. If it

still doesn't work, please replace the controller and

notify the manufacturer.

DSP block read

and write

EEPROM failure

Electrical

overspeed

protection

HMI block read

and write

EEPROM failure

Needle guard sensor is not adjusted, to adjust

the needle holder to protect the sensor, when

the foot is raised so that the sensor does no

t light, the presser feet completely down light

s

Motor locked-

rotor sector

errors

Disconnect the controller power supply, check whether

the motor power input plug fall off, looseness,

breakage, whether there is foreign body coil on the

nose. Rule out after restart the system still does not

work, please replace the controller and notify the

manufacturer.

Enter 222 parameter (motor lock) and change the

parameter value to 0. ② machine stuck, resulting in a

large instantaneous current, check the mechanical

failure.

Machine not i

nstalled needl

e protection

device detecte

d

1.165 7001 recovery; 2.turn off the needle prot

ection function, adjust the 244 parameter from

1 to 141.

The machine is

not in the

parking

position or is

not sensed to

the stop signal

1.press the reset button, 2.check the sensor is

damaged or poor wiring, requiring the signal wheel is

on the sensor is, the sensor lights.

Loading...

Loading...