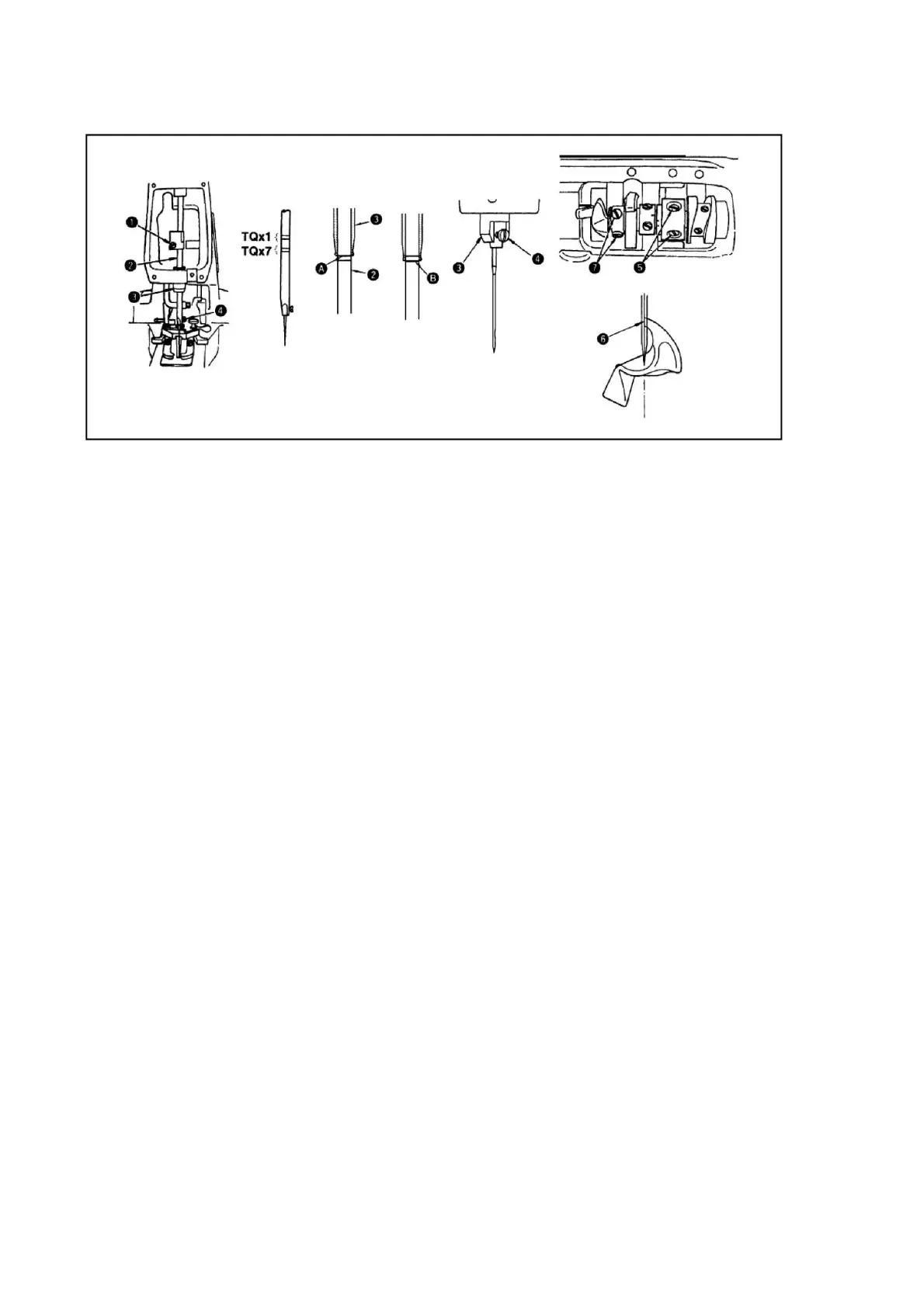

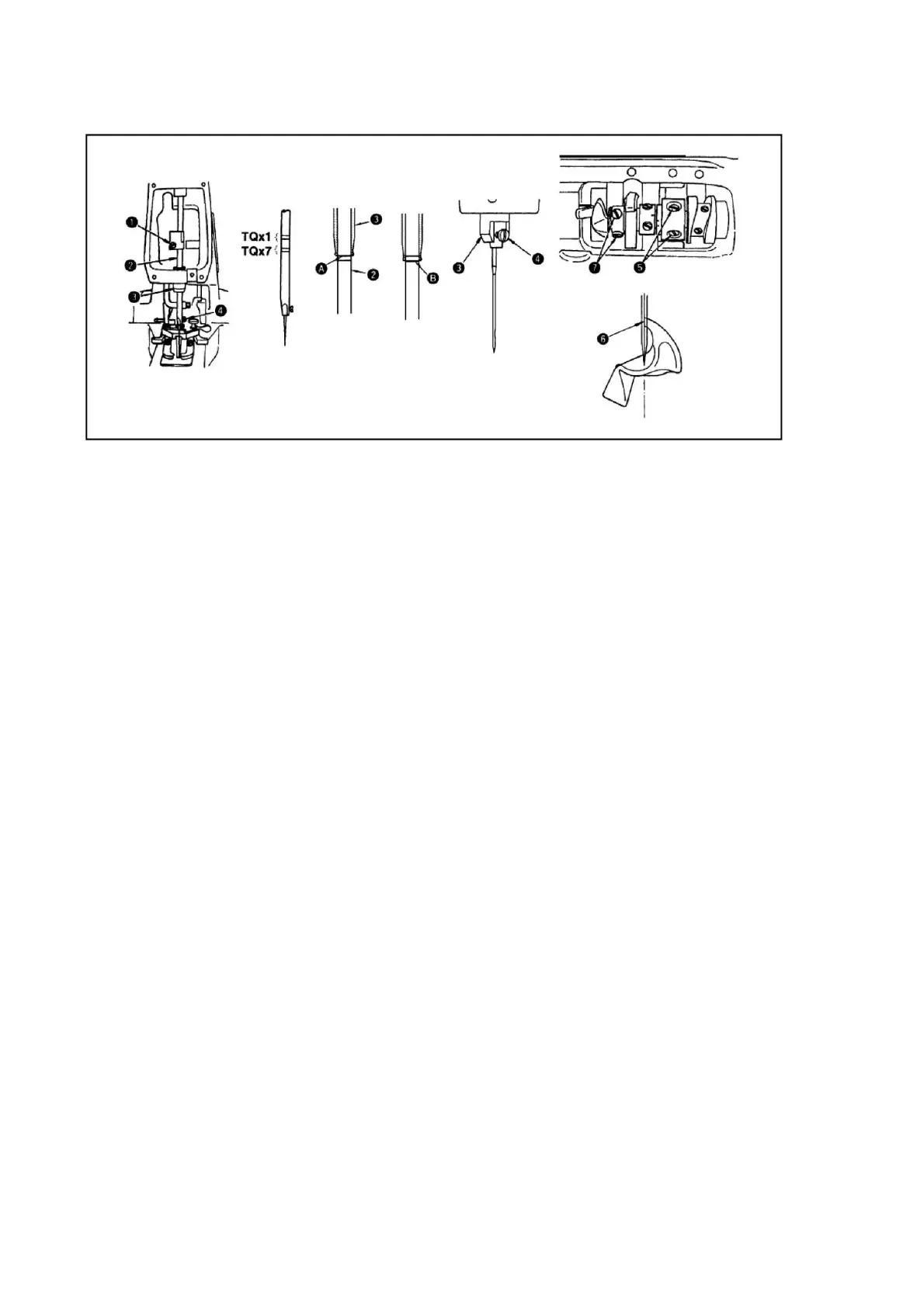

11.机针和弯针的关系(NEEDLE -TO-LOOPER RELATION)

★机针和弯针按照如下方法进行调整

(1)按转动方向驱动手轮,让针杆落到最下点,然后拧松固定螺丝(决定针杆高度)

(2)TQx1机针时,使用上方的2条刻线,TQx7机针时,使用下方的2条刻线,把其中的上

刻线A对准针杆下端块的下端,然后拧紧固定螺丝。这时应让机针固定螺丝4进入到避

免与针杆下端块相碰的沟槽里。(决定弯针的位置)

(3)拧松固定螺丝5,转动手轮,把针杆的2条一组的刻线中的下刻线B对准针杆下端块

的下端。

(4)在此状态,把弯针的针尖6对准机针的中心,然后拧紧固定螺丝5.

(5)拧松固定螺丝7,把弯针间隙调整为0.01~0.1mm,在拧紧螺丝7.

★ Adjust the needle-to-looper relation as follows :

(1)Depress the pedal fully forward ,turn the needle driving pulley in the

normal sewing direction to bring down the needle bar to the lowest point of

its stroke and loosen screw

(Adjusting the needle bar height )

(2)Adjust the height of the needle bar using top two lines engraved on the

needle bar for the TQx1 needle and using the bottom two lines for the TQx7

needle .Align the upper line A with the bottom end face of needle bar bushing

(lower) and tighten screw in the way that needle clamp screw 4 rests in

the slot of the needle bar bushing (lower )

(3) Looper screws 5 and turn by hand the needle driving pully until lower

line B of two lines aligns with the bottom end face of needle bar bushing

(lower)

(4) By keeping the machine in this state ,align looper blade 6 with the

center of the needle and tighten screws 5

(5) Loosen screws 7 and provide a 0.01to 0.1 mm clearance between the

looper and the needle .tighten screws7.

Loading...

Loading...