GB-11

JACOBSEN AR3

NARROW WIDTH OF CUT FIELD KIT

FITTING INSTRUCTIONS

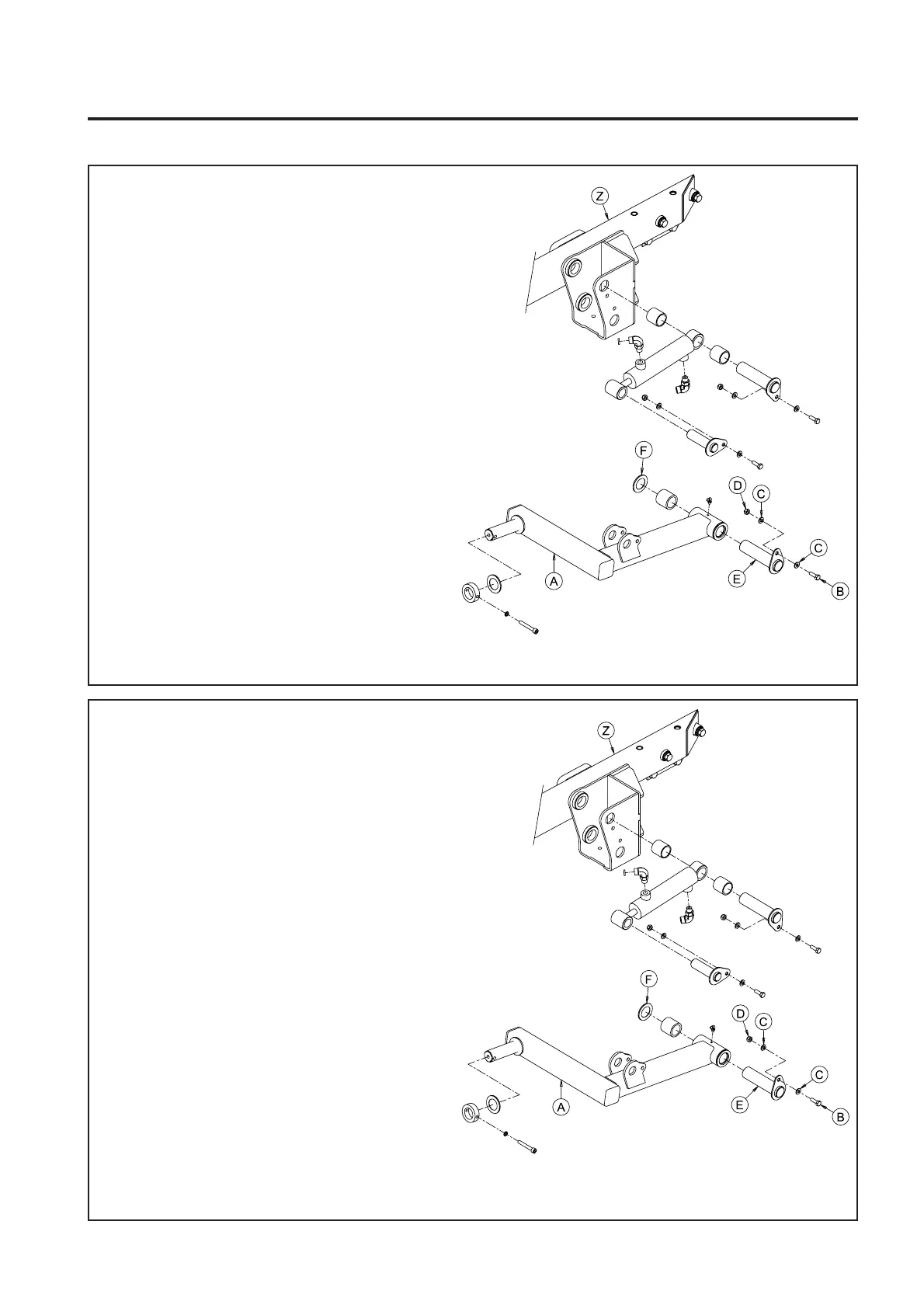

5.3 REMOVE LIFT ARM FROM MAINFRAME

1. Remove M8 x 25 Hex Head Screw (B), M8

Plain Washer (C) and M8 Nyloc Nut (D) from

Lift Arm Pivot Pin (E). Retain for future use.

2. Remove Lift Arm Pivot Pin (E) from Mainframe

(Z) / Lift Arm (A). Retain for future use.

3. Remove Lift Arm (A) from Mainframe (Z). Retain

Nylon Washers (F) for future use.

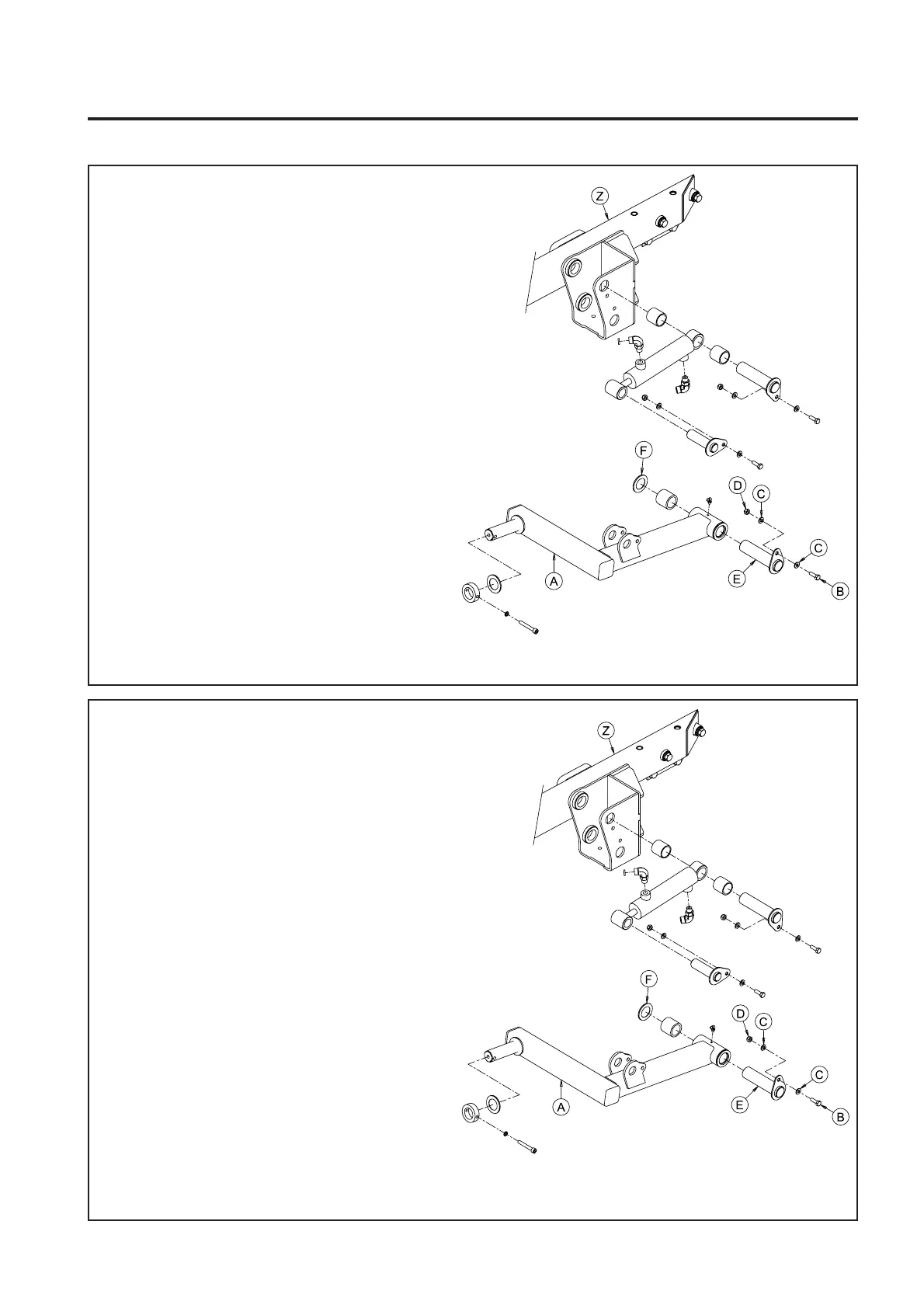

5.4 ASSEMBLE NEW LIFT ARM TO

MAINFRAME

1. Smear bore of new Lift Arm (A) bushes with

Shell Darina R2 grease (or equivalent).

2. Clean surface of Lift Arm Pivot Pin (E) (removed

in Step 5.3.2) to remove old grease residue.

3. Smear Lift Arm Pivot Pin (E) with Shell Darina

R2 grease (or equivalent).

4. Fit new Lift Arm (A) to Mainframe (Z) fitting

Nylon Washers (F) between the Mainframe

Plates and the Lift Arm (A) Pivot Housing.

5. Align holes in Lift Arm (A), Nylon Washers (F)

and Mainframe (Z).

6. Fit Lift Arm Pivot Pin (E) through Mainframe (Z),

Nylon Washers (F) and Lift Arm (A) Pivot

Housing.

7. Align hole in Lift Arm Pivot Pin (E) Flange Plate

with hole in Mainframe (Z) Plate.

5 CENTRE LIFT ARM

Loading...

Loading...