GB-8

JACOBSEN AR3

NARROW WIDTH OF CUT FIELD KIT

FITTING INSTRUCTIONS

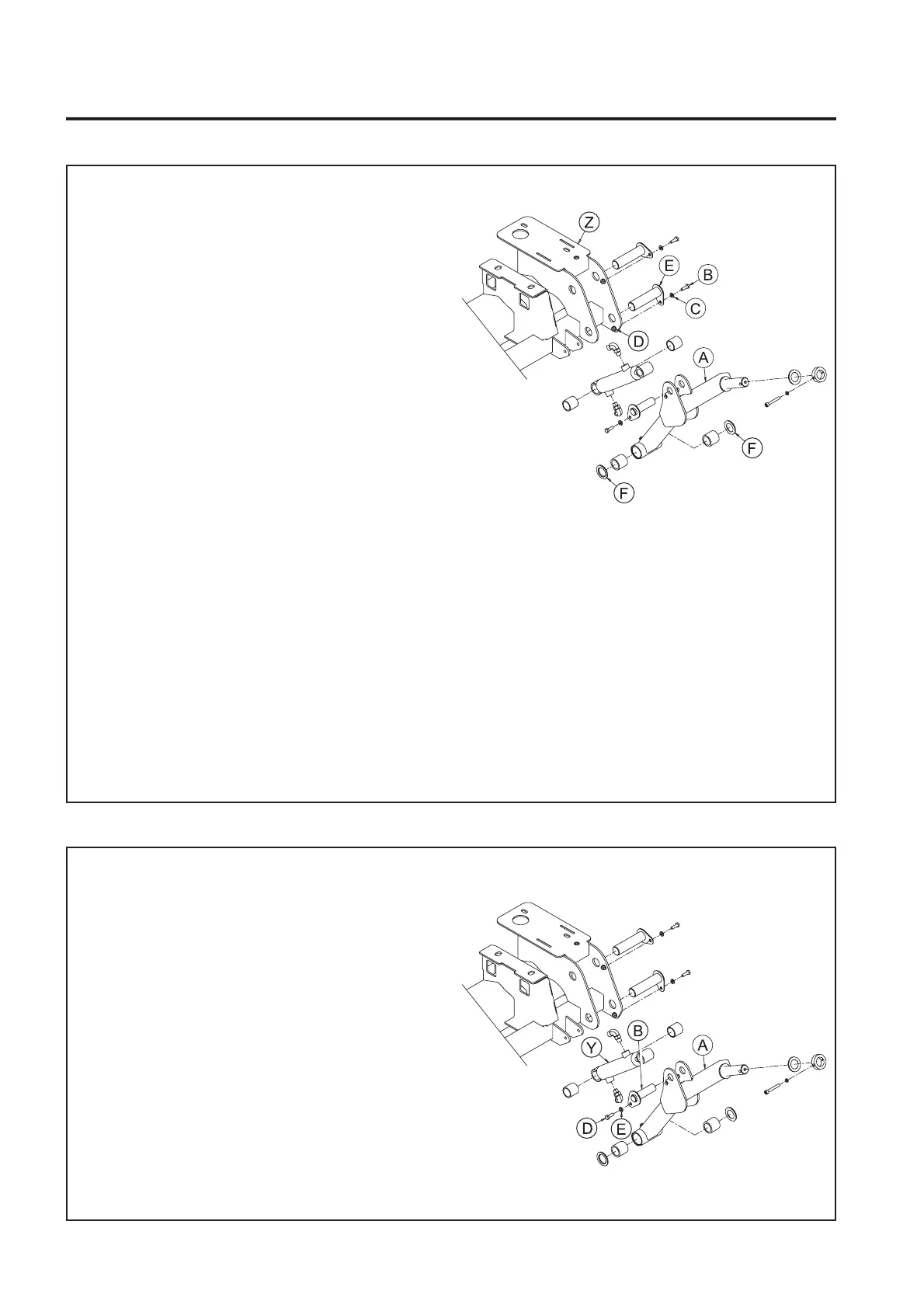

4.4 ASSEMBLE NEW LIFT ARM TO FRONT

AXLE

1. Smear bore of new Lift Arm (A) bushes with

Shell Darina R2 grease (or equivalent).

2. Clean surface of Lift Arm Pivot Pin (E) (removed

in Step 4.3.2) to remove old grease residue.

3. Smear surface of Lift Arm Pivot Pin (E) with

Shell Darina R2 grease (or equivalent).

4. Fit new Lift Arm (A) to Front Axle (Z) fitting

Nylon Washers (F) between the Front Axle (Z)

Plates and the Lift Arm (A) Pivot Housing.

5. Align holes in Lift Arm (A), Nylon Washers (F)

and Front Axle (Z).

6. Fit Lift Arm Pivot Pin (E) through Front Axle (Z),

Nylon Washers (F) and Lift Arm (A) Pivot

Housing.

Note - Lift Arm Pivot Pin (E) is assembled so

that the flange plate is on the outside of the

machine.

7. Align hole in Lift Arm Pivot Pin (E) Flange Plate

with hole in Front Axle (Z) Plate.

8. Reassemble hardware (B, C and D) (removed in

Step 4.3.1) to Lift Arm Pivot Pin (E) and Front

Axle (Z).

4 FRONT LH LIFT ARM

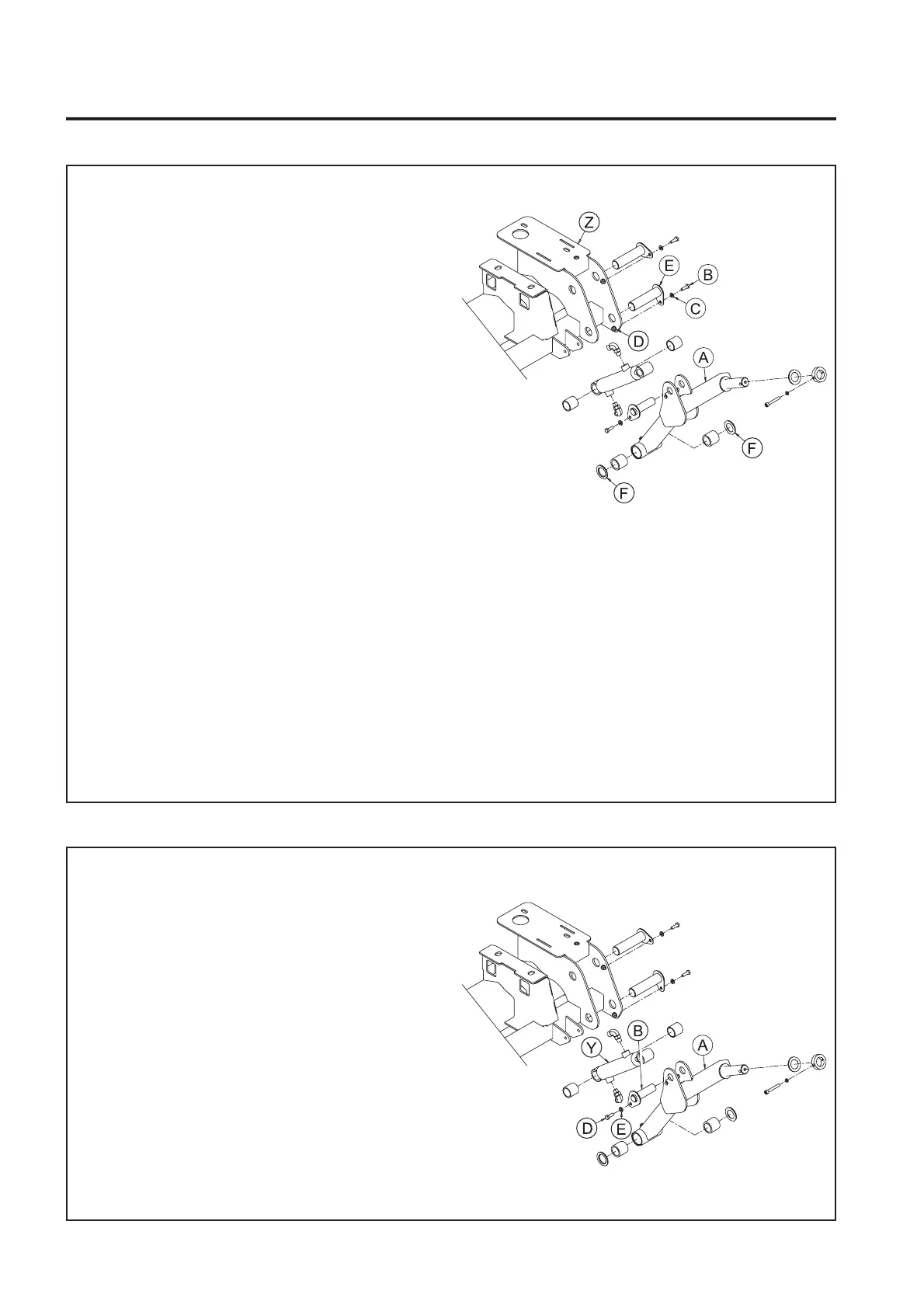

4.5 RECONNECT LIFT RAM TO LIFT ARM

1. Align holes in Lift Ram (Y) and Lift Arm (A).

2. Clean surface of Ram Pin (B) (removed in Step

4.2.1) to remove old grease residue.

3. Smear surface of Ram Pin (B) with Shell Darina

R2 grease (or equivalent).

Note - Ram Pin (B) is assembled so that the

flange plate is on the inside of the Lift Arm (A).

4. Align holes in Ram Pin (B) with slot in Lift Arm

(A) Plate.

Loading...

Loading...