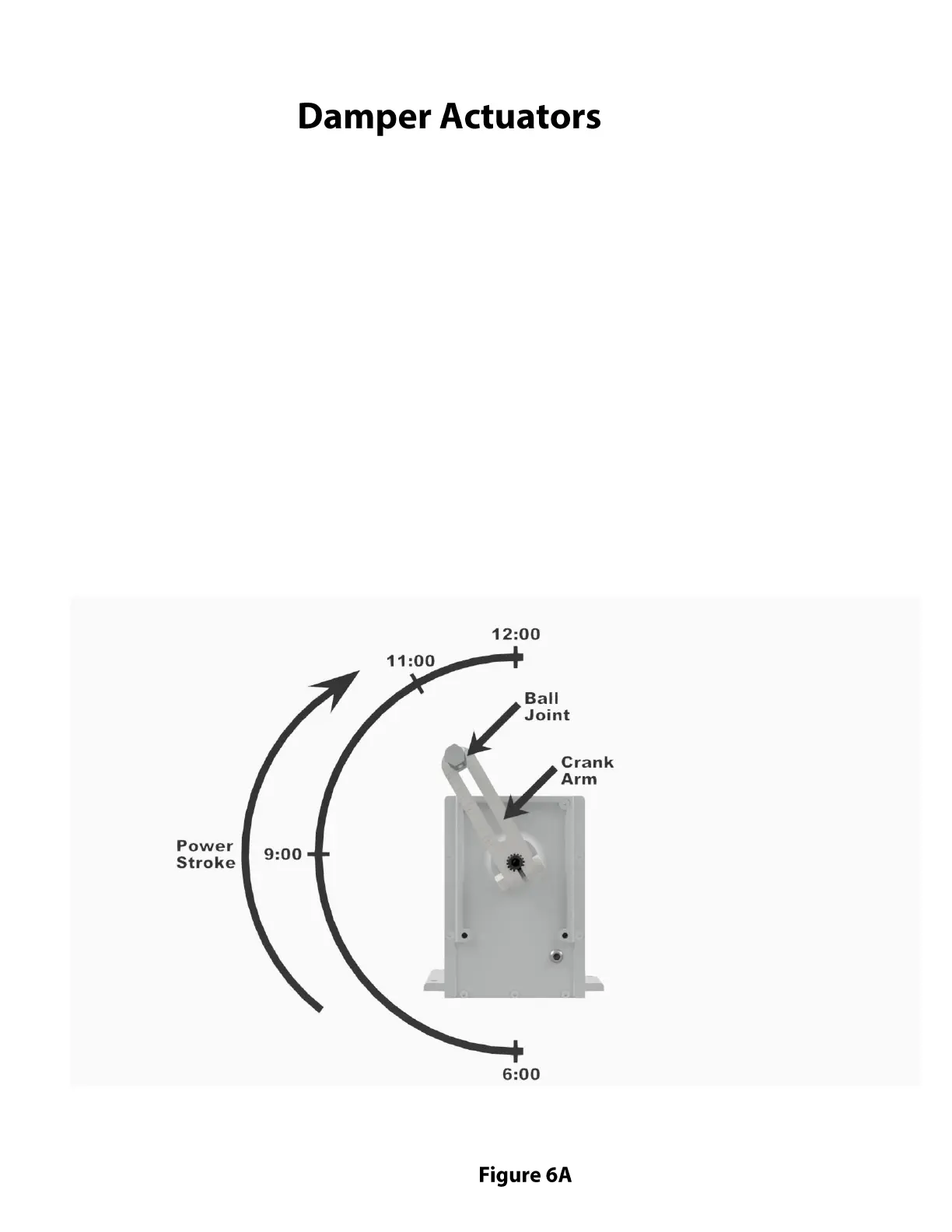

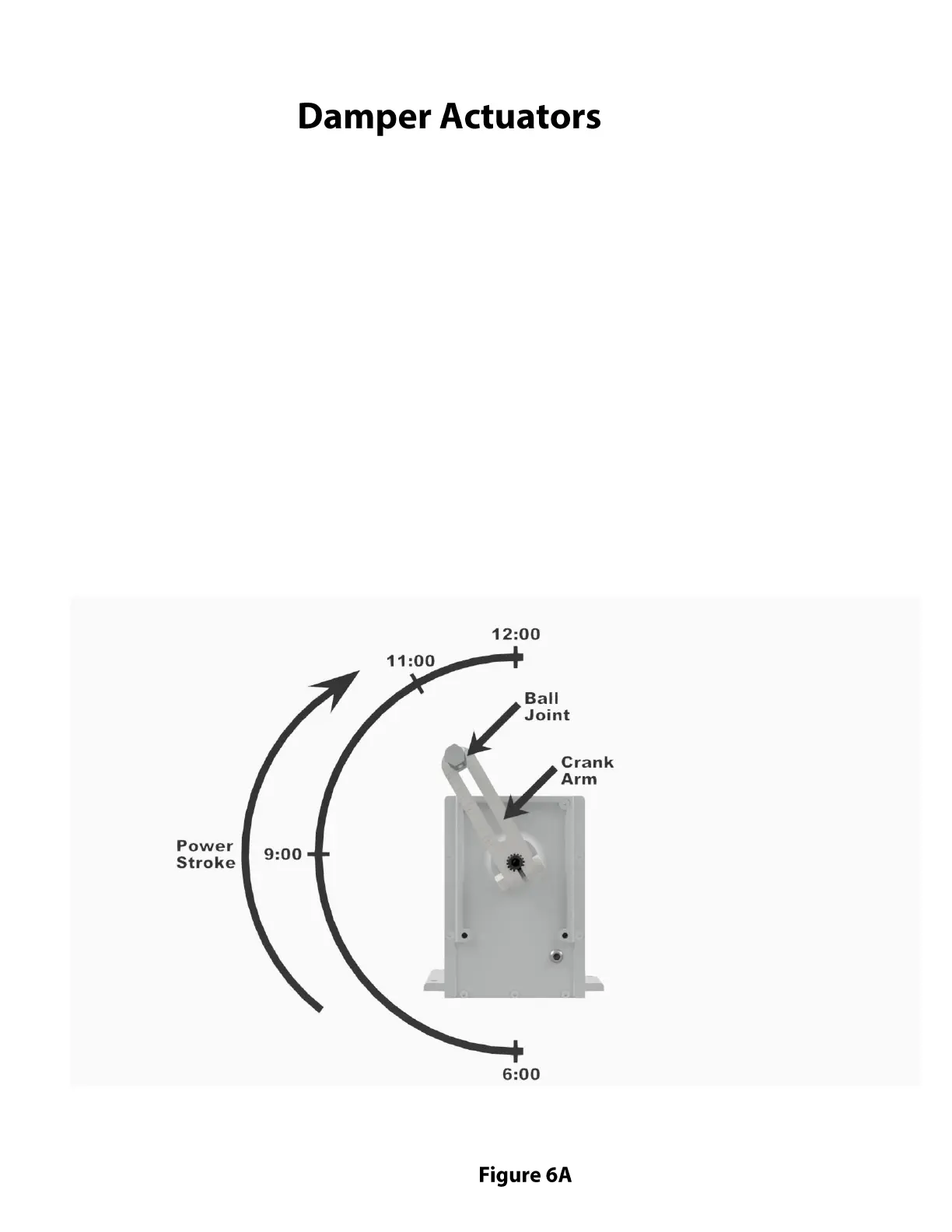

Actuator is shown in energized mode

(clockwise travel, full stop position) with

crank arm installed in recommended

position. This is the "damper open" position

Oyler Pits utilize two damper actuators, one for temperature control and one for the “ Evac” mode.

Older units have Barber-Colman actuators and newer units have Schneider Electric actuators. They

are identical, other than the name, as Schneider acquired Barber-Colman. Instructions for the actuators

are included in this manual (see the Thermostats and Actuator Manuals section). The model for 120 Volt

units is MA-418.

These actuators are located on the top rear of the pit near the chimney connector. IMPORTANT: When

replacing or adjusting the actuator, it is critical that the motor is energized and allowed to reach its full

stop position before connecting the linkage rod from the dampers to the ball joint on the “crank arm”

(during the power stroke the output shaft travels 180 degrees shaft to reach its stopping point). If the

actuator cannot reach this stopping point, it will overheat and fail. With the actuator energized, the crank

arm should be installed so that it is in the 11 o’clock position or approximately 150 degrees from the

vertically down position (see drawing). After installing the crank arm in the proper position and connecting

the linkage rod (with the associated dampers open*) to the ball joint on the crank arm, the device should

be cycled (off and on) several times to make sure there is no binding in the linkage components which

would shorten the travel of the power stroke. Also, make sure the appropriate dampers fully close when

the actuator is de-energized. It is also recommended that this test phase also include the use of an amp

meter to determine that the actuator has in fact reached its full travel stop position when energized. The

amp reading for 120 Volt units should drop from approximately 0.9 A (running) to 0.3A (stopped or holding).

Loading...

Loading...