19

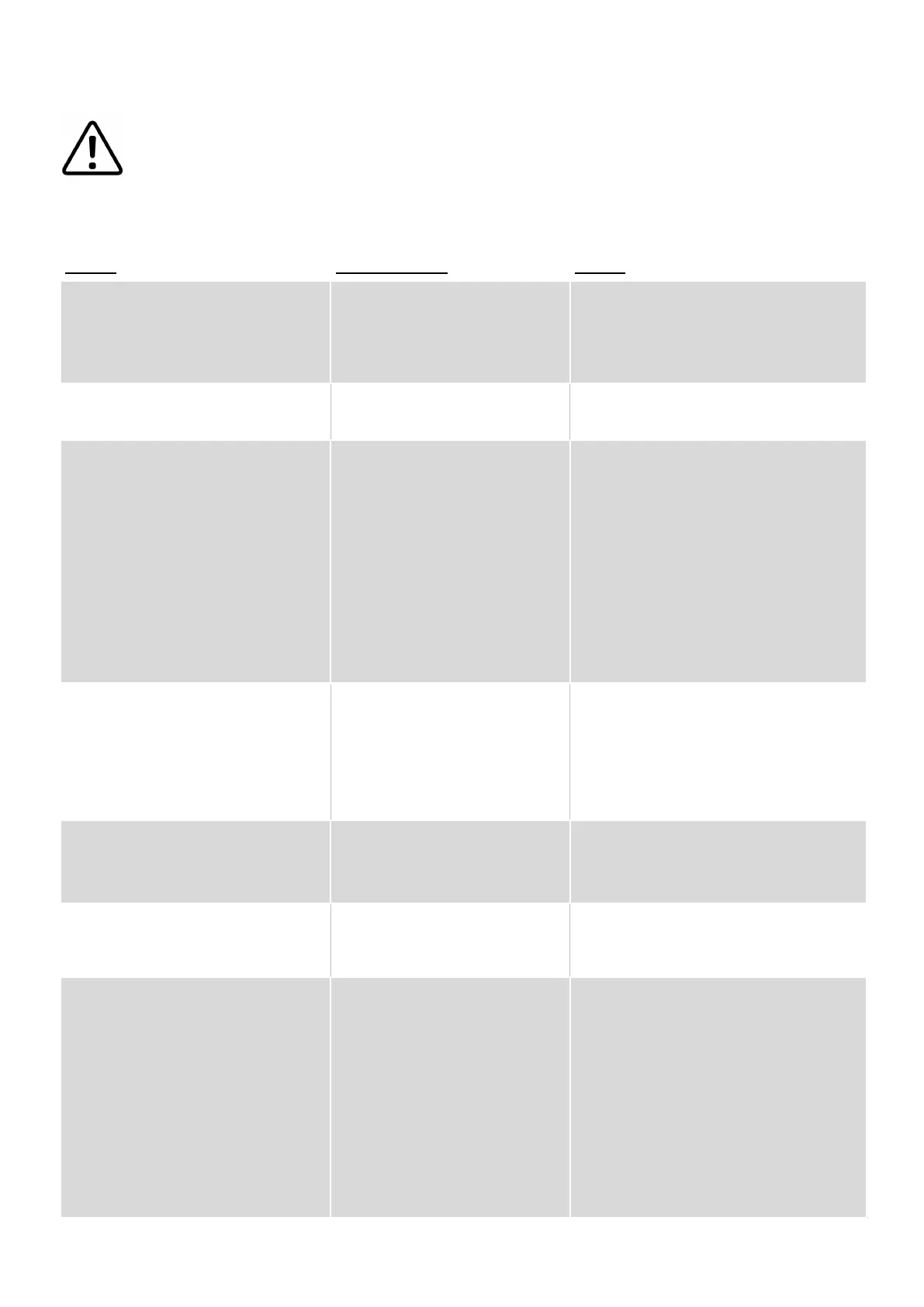

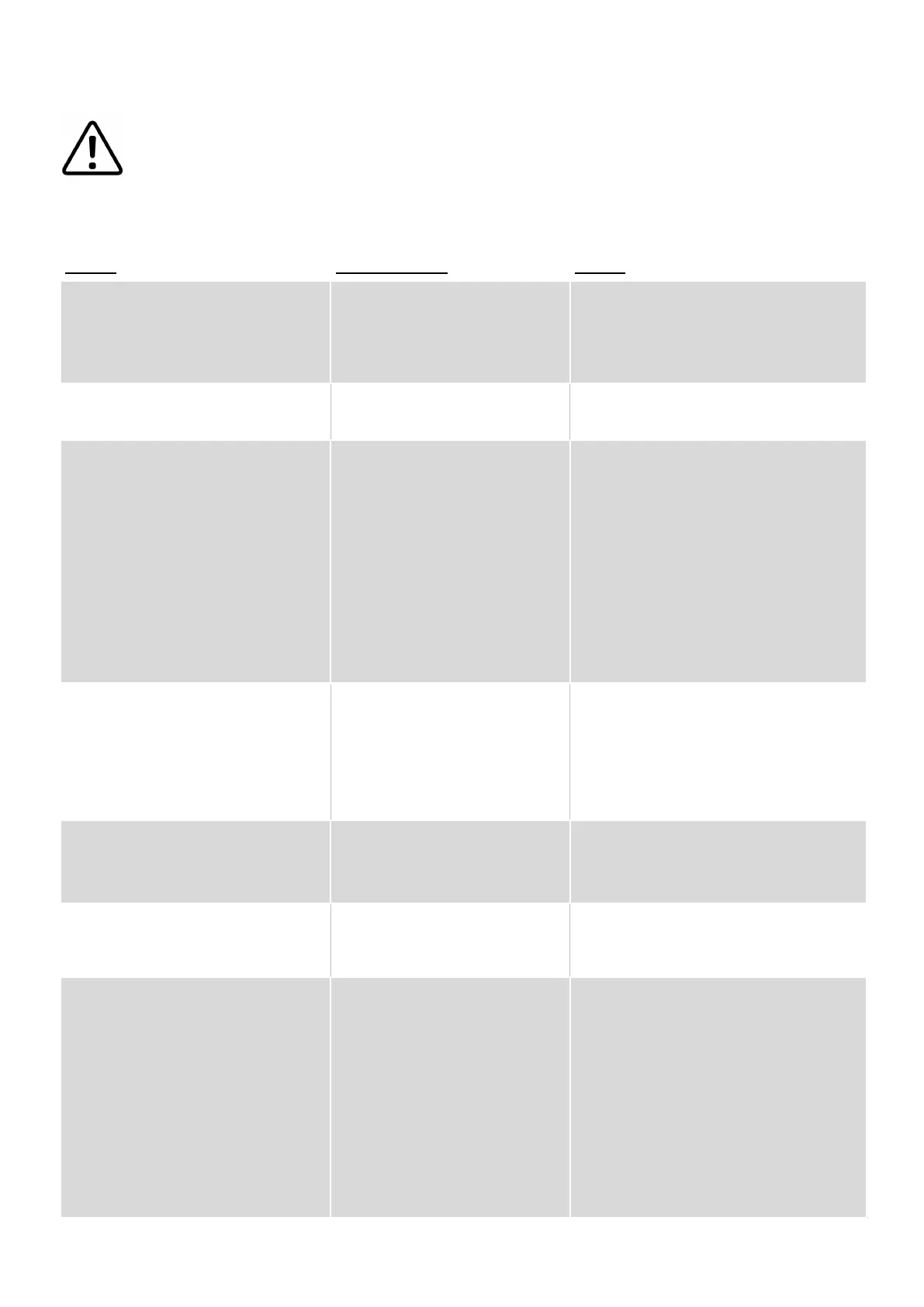

MMA WELDING PROBLEMS

Before starng any welding acvity ensure that you have suitable eye protecon and

protecve clothing. Also take the necessary steps to protect any persons within the welding

area.

Arc welding defects and prevenon methods

Defect Possible cause Acon

Excessive spaer (beads of metal

scaered around the weld area)

Amperage too high for the

selected electrode

Reduce amperage or ulise larger

diameter electrode

Voltage too high or arc length

too long

Reduce arc length or voltage

Uneven and errac weld bead and

direcon

Weld bead is inconsistent and

misses joint due to operator

Operator training required

Lack of penetraon – The weld bead

fails to create complete fusion

between material to be welded,

oen surface appears okay but weld

depth is shallow

Poor joint preparaon

Insucient heat input

Poor weld technique

Joint design must allow for full access

to the root of the weld

Material too thick

Increase the amperage or

increase the electrode size

and amperage

Reduce travel speed

Ensure the arc is on the

leading edge of the weld puddle

Porosity – Small holes or cavies on

the surface or within the weld

material

Work piece dirty

Electrode is damp

Arc length is excessive

Remove all contaminant from the

material i.e. oil, grease, rust, moisture

prior to welding

Replace or dry the electrode

Reduce the arc length

Excessive penetraon – The weld

metal is below the surface level of

the material and hangs below

Heat input too high

Poor weld technique

Reduce the amperage or use a smaller

electrode and lower amperage

Use correct welding travel speed

Burning through – Holes within the

material where no weld exists

Heat input too high Use lower amperage or smaller

electrode

Use correct welding travel speed

Poor fusion – Failing of weld material

to fuse either with the material to be

welded or previous weld beads

Insucient heat level

Poor welding technique

Work piece dirty

Increase the amperage or increase the

electrode size and amperage

Joint design must allow for full access to

the root of the weld

Alter welding technique to ensure

penetraon such as weaving, arc

posioning or stringer bead technique

Remove all contaminant from the

material i.e. oil, grease, rust, moisture

prior to welding

Loading...

Loading...