7

JB INDUSTRIES • ELIMINATOR OPERATING MANUAL • 800.323.0811 • SALES@JBIND.COM • JBIND.COM

and the less rubbing together. This decrease in friction changes the temperature

around those molecules and the JB digital vacuum gauge is registering those

changes by way of temperature changes at the sensor’s filament. The environment

inside a system being evacuated has more instability at higher micron levels (9000

to 1000) than at lower micron levels (700 to 50). This is evidenced when testing

JB digital vacuum gauges at the different ranges on a secured system. When in the

range of 4000 microns, the gauge display will show 4000 microns, then jump to

4350, then regress to 3875, then jump back to 4000. After being blanked-off at this

level for a period of time, the changing back and forth will level out to changing

from the incremental display of 4000 microns and the next incremental display up

or down of either 4125 or 3875. But, when in a deeper vacuum like 350 microns,

the changes in display on increments may be from 350 to 357 and back down to

350 or even 329 as the environment inside the system becomes more stable and

the time period of these changes will be less as most of the out gassing has been

done. (Figure 17).

Breaking Vacuum

Breaking vacuum prior to shut down is important on larger CFM pumps. This

procedure relieves the stress on the flexible coupler on the next start up. When a

pump is shut down without breaking vacuum, the oil in the cover is pulled back

into the cartridge and intake chamber of the pump trying to fill the vacuum there.

Upon the next start up the pump has to clear the oil out of these areas and all the

stress is on the flexible part of the coupler, especially if the oil is cold. You can see

this occurring by shutting down the pump and watching the sight glass. The oil

will start to drop down and appears as if you are low on oil. Then when you restart

the pump the oil level returns to normal.

To break vacuum on the PLATINUM

®

vacuum pumps, simply close the isolation

valve with the pump still running and open the gas ballast valve all the way and

allow the pump to run 2-3 seconds with the gas ballast valve opened and then shut

pump off and close the valve.

To break vacuum on the Eliminator vacuum pumps. After blanking off at the

manifold or an external isolation valve, if used, crack open the unused intake port

on the pump and allow to run 2-3 seconds and shut pump off.

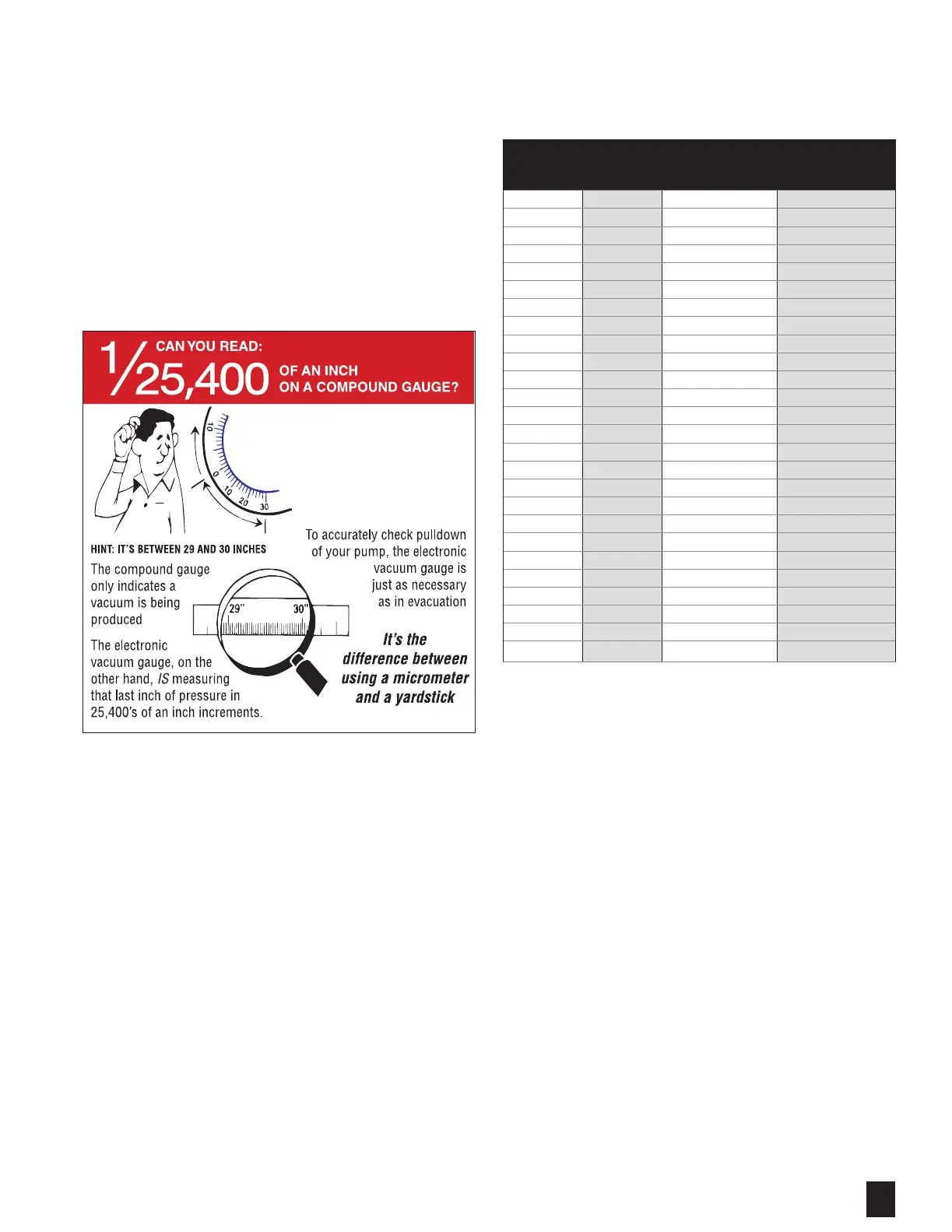

CROSS REFERENCE OF

VACUUM MEASUREMENTS

Boiling temperature of water at converted pressures (Figure 18).

TEMP. F° MICRONS

INCHES OF HG

VACUUM

PRESSURE POUNDS

SQ. IN.

212 759,968 0.00 14.696

205 535,000 4.92 12.279

194 525,526 9.23 10.162

176 355,092 15.94 6.866

158 233,680 20.72 4.519

140 149,352 24.04 2.888

122 92,456 26.28 1.788

104 55,118 27.75 1.066

86 31,750 28.67 0.614

80 25,400 28.92 0.491

76 22,860 29.02 0.442

72 20,320 29.12 0.393

69 17,780 29.22 0.344

64 15,240 29.32 0.295

59 12,700 29.42 0.246

53 10,160 29.52 0.196

45 7,620 29.62 0.147

32 4,572 29.74 0.088

21 2,540 29.82 0.049

6 1,270 29.87 0.0245

-24 254 29.91 0.0049

-35 127 29.915 0.00245

-60 25.4 29.919 0.00049

-70 12.7 29.9195 0.00024

-90 2.5 29.9199 0.00005

--- 0.00 29.92 0.00000

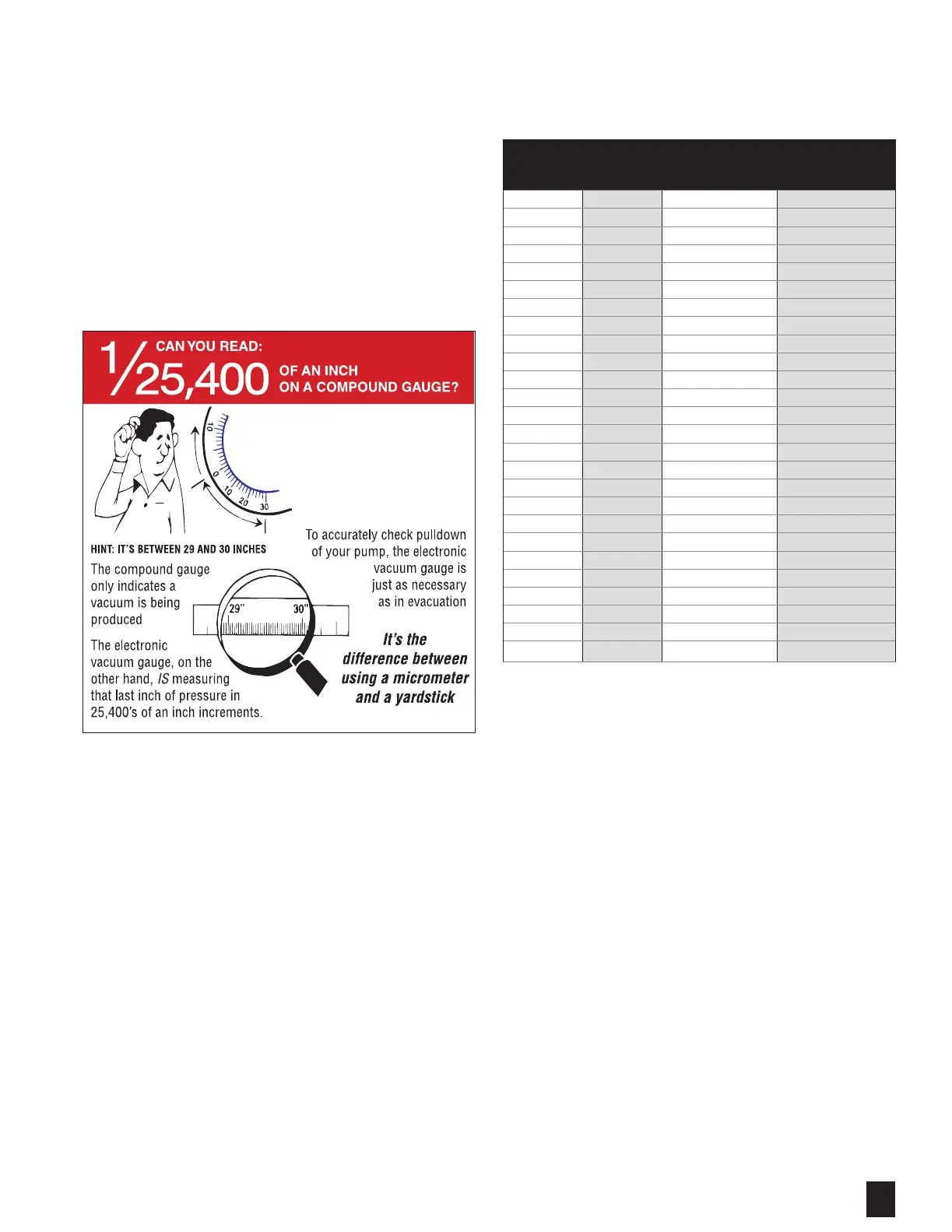

MEASURING VACUUM IN

MICRONS OR INCHES?

Figure 17

Figure 18

Loading...

Loading...