7.7 Valve

Open with the following steps:

Settings key > select Valve > press OK > select “auto”, “man open” or “man shut” > press OK.

In this menu item you can select the operation mode of the externally controlled solenoid valve� The options are automatic operation (auto), manual

open (man open) and manual shut (man closed)� For the regulation feature to work, the “auto“ setting (factory setting) needs to be selected� For the

settings “man open “ and “man closed“, the valve stays open or shut until the setting is changed again�

A green symbol for “open“ or a red symbol for “shut“ and “A“ for automatic or “m“ for manual appear on the value overview (chap� 4)�

7.8 Alarm

The device has a versatile alarm function for the pH value and temperature�

Open with the following steps:

Settings key > select Alarm > press OK > use selection key to select alarm type (“alarm o ”, “flashing”, “flashing and tone”) > press OK

> select your chosen limit values for pH and temperature with „plus“ and „minus“ > press OK.

pH alarm:

If the current pH value in the aquarium exceeds the set target value upwards or downwards by more than the value entered, a warning triangle will

flash on the display and the pH value indication will change to red and flash (if “flashing” was selected)� Where “flashing and tone” was selected, an

acoustic signal will sound as well�

The alarm limit can be set as follows: +/- 0�10 to +/- 2�00 pH in steps of 0�05 pH� Factory setting: +/- 1�00 pH

Tip: We recommend setting the alarm value for the pH to +/- 0,50 to check the function of the CO₂ supply� If the device then triggers an alarm, check

your CO₂ system to see if the cylinder is empty or the supply amount has been adjusted etc�

Temperature alarm:

The temperature alarm function enables you to set the upper and lower alarm limits separately� Thus you can freely select the alarm limits relevant

to your aquarium� If one of the limit values is exceeded or not reached, the same occurs as for the pH alarm�

Factory setting: 20 °C < t < 30 °C

The limit values set appear in the status line on the value overview (chap� 4)�

7.9 Brightness

Open with the following steps:

Settings key > select Brightness > press OK > select the desired value using “plus” and “minus” > press OK.

Factory setting: middle level�

7.10 Contrast

Open with the following steps:

Settings key > select Contrast > press OK > select the desired value using “plus” and “minus” > press OK.

Factory setting: middle level�

7.11 Key lock

Open with the following steps:

Settings key > select Key Lock > press OK > confirm with “locked“/”unlocked“ > press OK.

For selection “locked“ > enter the password (4-digit number) > press OK.

After locking the 4-space number field appears when any key is pressed� Enter the 4-digit password and confirm with OK� The keys are now unlo

-

cked again

� In the event that you have forgotten the password, you can unlock the device with the following master password: 7422�

In the value overview (chap� 4) a symbol for keys locked (red padlock locked) and for keys unlocked (green padlock unlocked) appears�

7.12 Software version

Open with the following steps:

Settings key > select software version > press OK

The version of the software currently installed and the serial number of the device are displayed� This information is only required for service purpo

-

ses

�

7.13 Reset function

Open with the following steps:

Settings key > select “Restore all factory” > press O.K.

If you press longer than 1 sec on OK, all individual settings will be deleted and reset to the factory setting. The master password

7442 is retained.

Factory setting after reset:

Language: German

Calibration reminder: 30 days

Auto pH: ON, KH 8 / pH 7�03

Hysteresis: 0�10

Valve: auto

Alarm: pH +/- 1,00; 20 °C < t < 30 °C

Brightness: medium value

Contrast: medium value

Key lock: unlocked

Master password: 7422

8. Miscellaneous

8.1 Calibration

Display during waiting time: Whilst the sensor is in the buer solutions the device measures the sensor voltage delivered and waits until the signal

has stabilised� This takes a maximum of 1�5 minutes per buer solution�

The following appears on the display during the waiting time:

First line: pH value of the required buer solution and voltage in millivolt

Second line: temperature in °C

Third line: progress bar

The far right of the display also shows the current accuracy of the measurement, which is redefined for the sensor used during each calibration�

Example: +/- 0�02 pH� The higher this value is, the worse the condition of the sensor is�

Calibration reminder: the device has an automatic calibration reminder function which gives you a reminder for calibration every 30, 45 or 60

days� The time to the next calibration is displayed in days and hours in the value overview (chap� 4)� The remaining time display also appears on the

top right of the idle screen 5 days before the calibration period expires� Its colour changes to red two days before calibration is due� After the expiry

of the deadline the display flashes and counts the days with a minus sign, to remind you how many days the calibration is overdue for�

If calibration cannot be carried out at that moment, the device continues to measure and control as before� However, the warning signal (flashing)

can only be cancelled by calibration�

The time to the next calibration can only be recorded as long as the device is connected to the power supply� After a longer pause, it is vital that

calibration is carried out before the device is again used to measure and regulate�

Error messages during or after the calibration:

The measuring behaviour of pH sensors changes with age i�e� it begins to deviate from the original setting� Regular re-calibration of the device (com

-

parison with the changed measuring behaviour of the sensors) is vital to obtain reliable results

� As a rule, the more often, the better�

If, at the end of the calibration process, the symbol of the operating instructions and an error message such as DELTAV, OFFSET or similar appear, the

sensor may be defective� Then repeat the calibration�

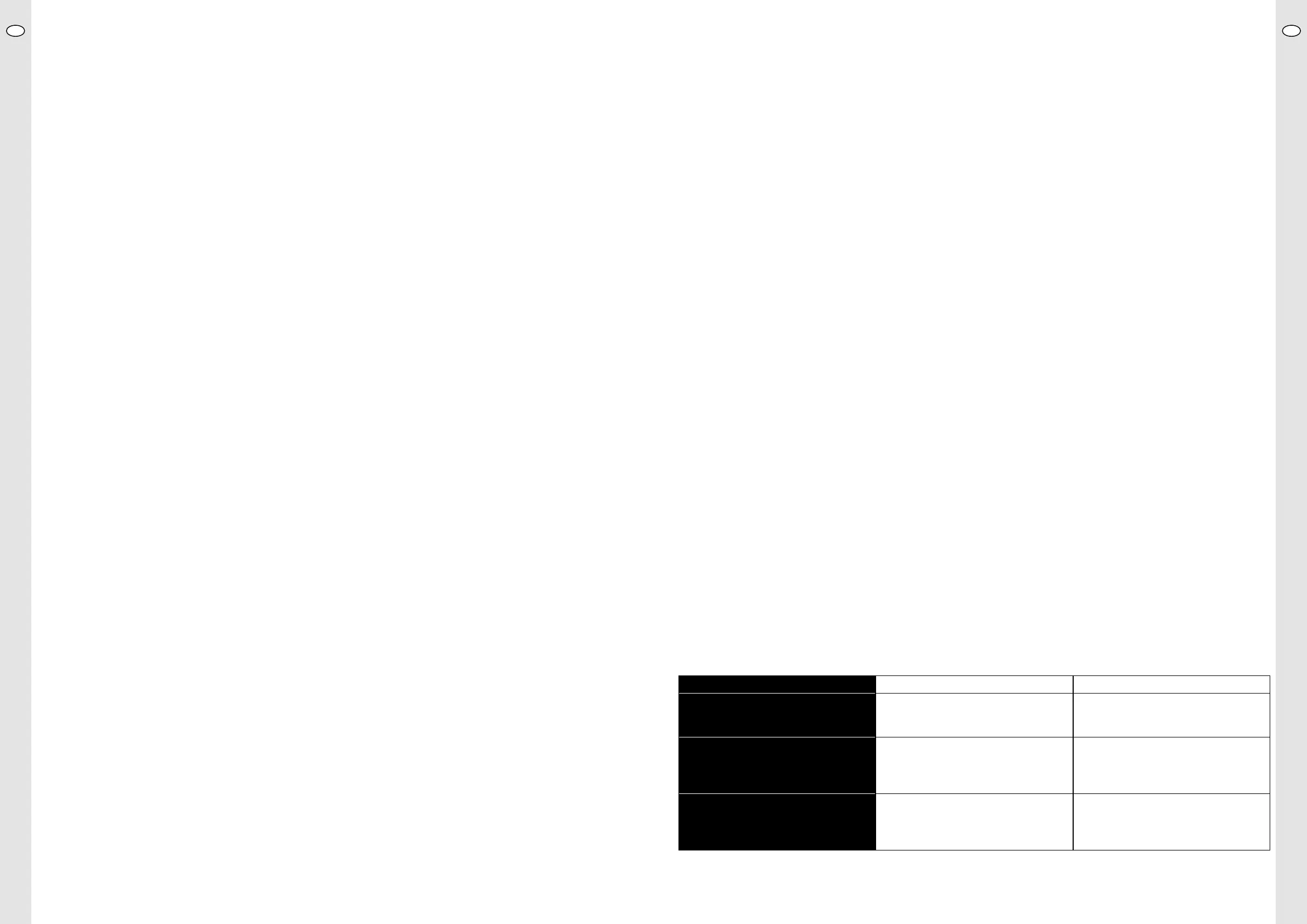

In the event that calibration is unsuccessful a second time, consult the following table:

Error message Cause Solution/Action

DELTAV Voltage dierence per full pH unit is less than

35 mV: sensor too old or accidentally calibrated

twice with same buer solution�

Repeat calibration, check correct buer

solution is used� If unsuccessful, connect new

sensor and calibrate�

OFFSET Sensor voltage at pH 7�00 is outside the range:

sensor too old, cable faulty, no sensor connec-

ted or initially calibrated with buer solution

4

�00 by accident�

Check sensor cable for damage, connect

sensor correctly and repeat calibration (starting

with buer solution 7�00!)� If unsuccessful,

connect new sensor and calibrate�

UNSTAB Unstable sensor voltage: sensor tip soiled,

electrolyte leaked out of sensor or sensor tip

broken o�

Clean sensor tip� If unsuccessful, connect new

sensor and calibrate�

UKUK

22 23

Loading...

Loading...