5 - 2

Section J

Track and Running Gear

9803/6400

Section J

5 - 2

Issue 2*

Grease Cylinder (continued)

Removal (continued)

!!

WARNING

RECOIL UNITS ARE DANGEROUS. They must not be

dismantled without using suitable tools to compress the

spring safely. The spring pressure can cause serious

injury if suddenly released. Scrap units must be made

harmless by compressing the spring in a hydraulic press

and cutting through the end of the shaft before slowly

releasing the pressure.

TRACK 1-10

Note: If it becomes necessary to dismantle the recoil spring

assembly, the following procedure should be used.

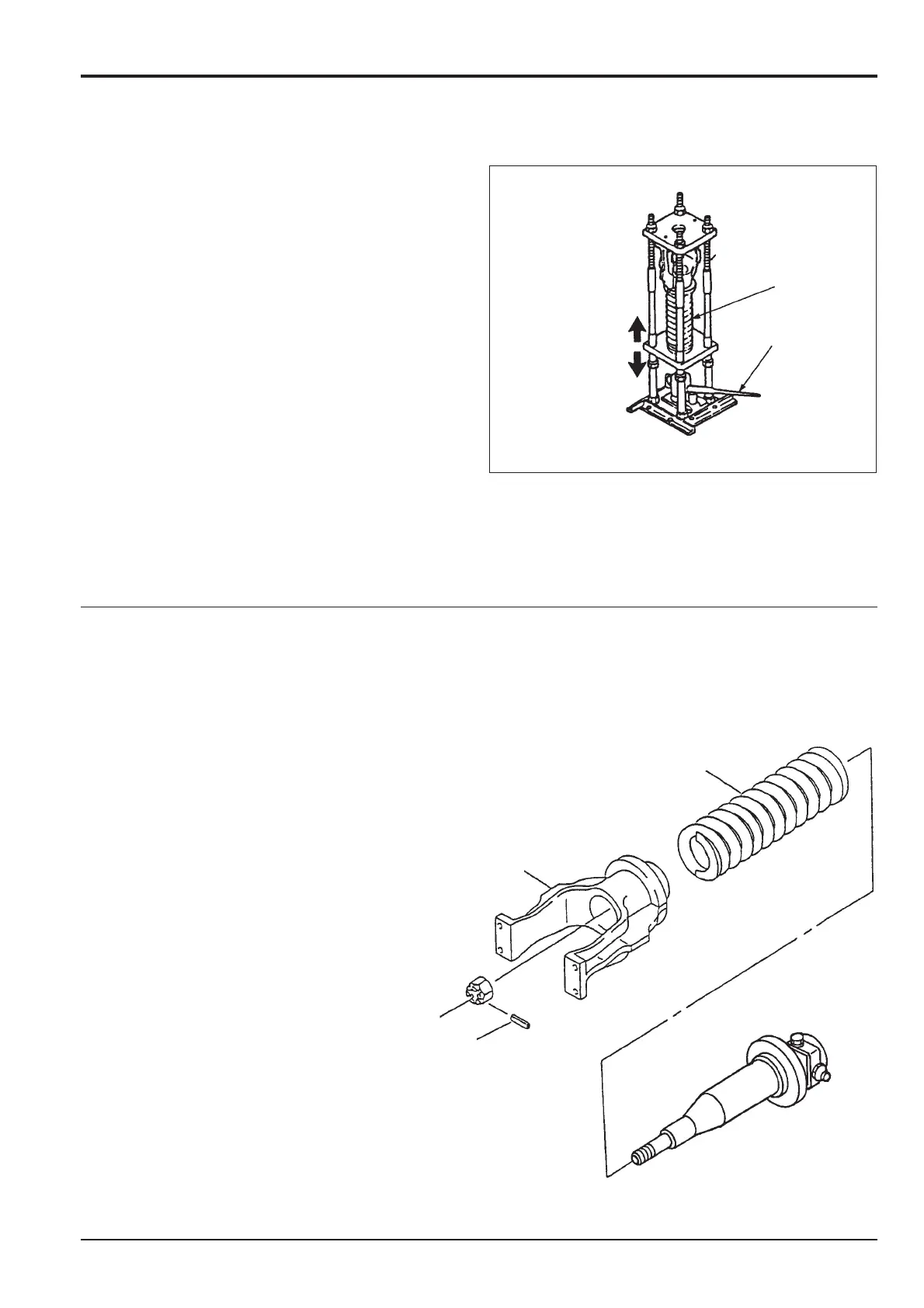

5. Prepare the jig for Recoil Spring Disassembly.

Place the re-coil spring unit as shown.

Jack up the hydraulic jack A and compress the Recoil

Spring B.

6. Remove the Recoil Spring.

Pull out the Spring Pin C and remove the castellated nut

D. Let the jack A down to relieve the pressure on the

recoil spring B.

Remove the components from the jig, firstly the yoke E,

spring B and finally, the grease cylinder F.

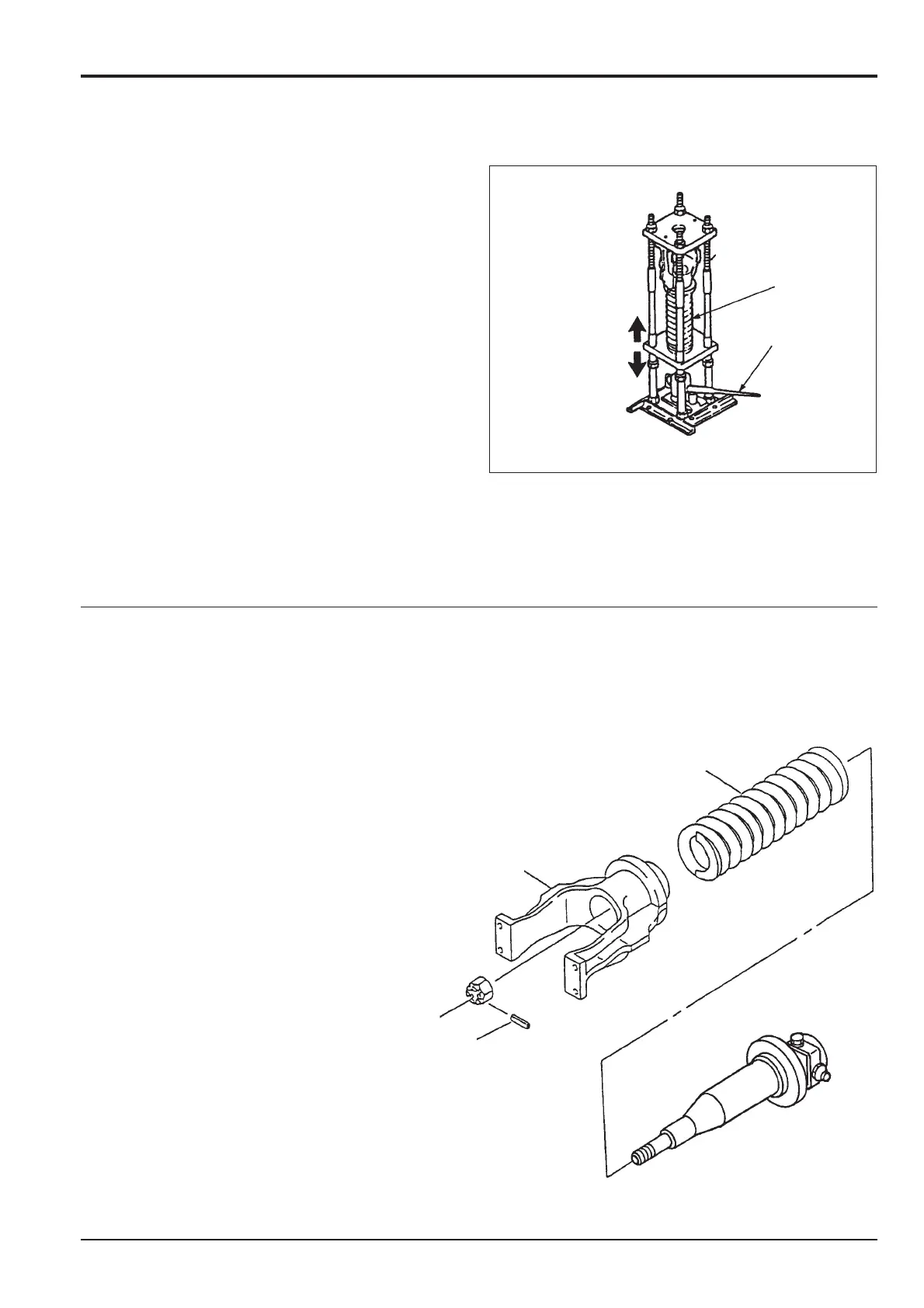

Replacement

1. Reassembly of Components.

a. Set the components in the jig, firstly the grease

cylinder F, then place the spring B on top, and

finally, the yoke E.

b. Extend jack A and compress recoil spring B.

c. Install the castellated nut D on the threaded section

of the grease cylinder F which protrudes through

the yoke E. Tighten nut D, aligning the castellations

with the pin hole.

d. Remove the recoil spring assembly from the jig.

See "Recoil Spring Installation".

e. Renew and install spring pin C.

f. Release jack A carefully and allow recoil spring B

to expand. Remove assembly from the jig.

B

A

B

E

D

C

F

*

*

*

*

*

*

*

*

*

*

Loading...

Loading...