Section 6 - Maintenance

6-16 5376000253

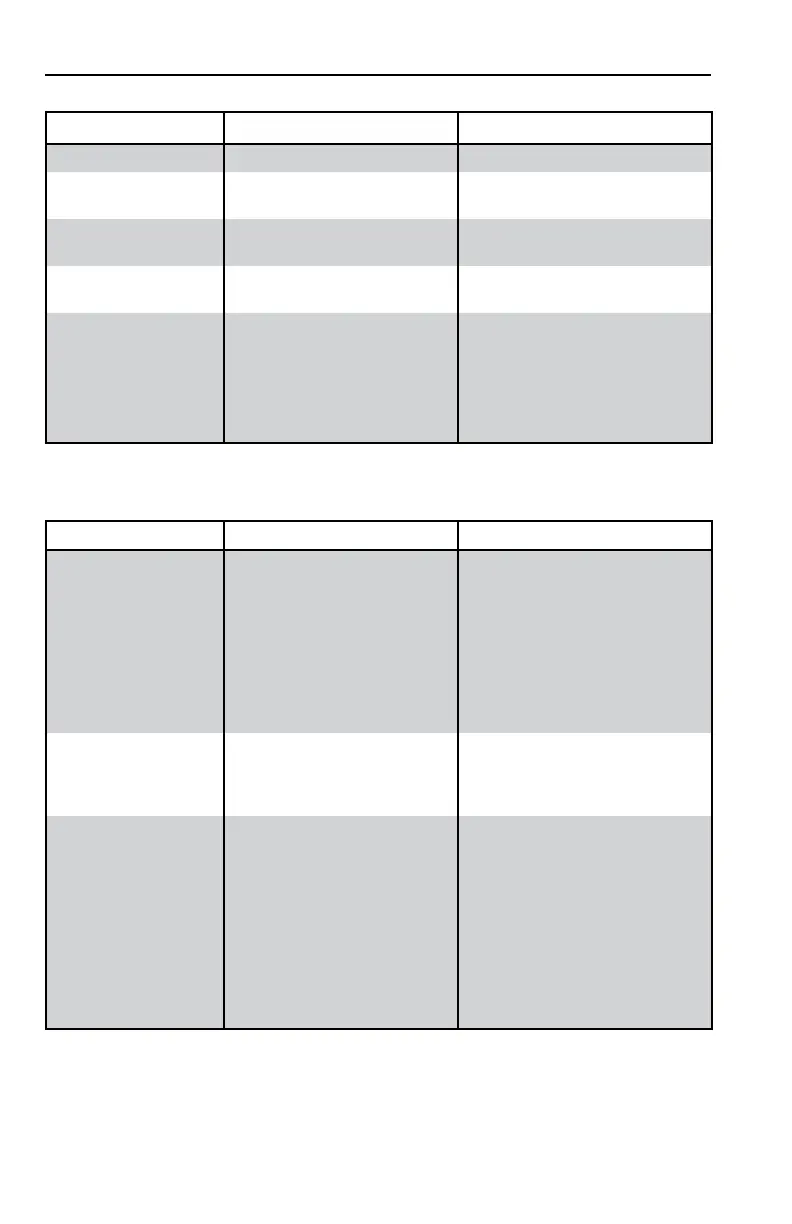

P.T.O. FUNCTIONING IMPROPERLY

Problem Cause Solution

Intermittent operation a. Poor Electrical connection a. Check electrical connections

Rattling noise in P.T.O. a. P.T.O. backlash too loose

(Consult P.T.O. Manual)

a. Shims must be removed

Howling noise in

P.T.O.

a. P.T.O. backlash too tight

(Consult P.T.O. Manual)

a. Shims must be added

Gear oil leak between

P.T.O. and pump

a. Defective shaft seal a. Remove and replace

P.T.O. will not engage

or disengage

a. Electrical circuit wiring

b. Solenoid Valve

malfunctioning

c. Blown fuse

a. Check/repair electrical wiring

problem circuit.

b. Repair or replace

c. Replace fuse

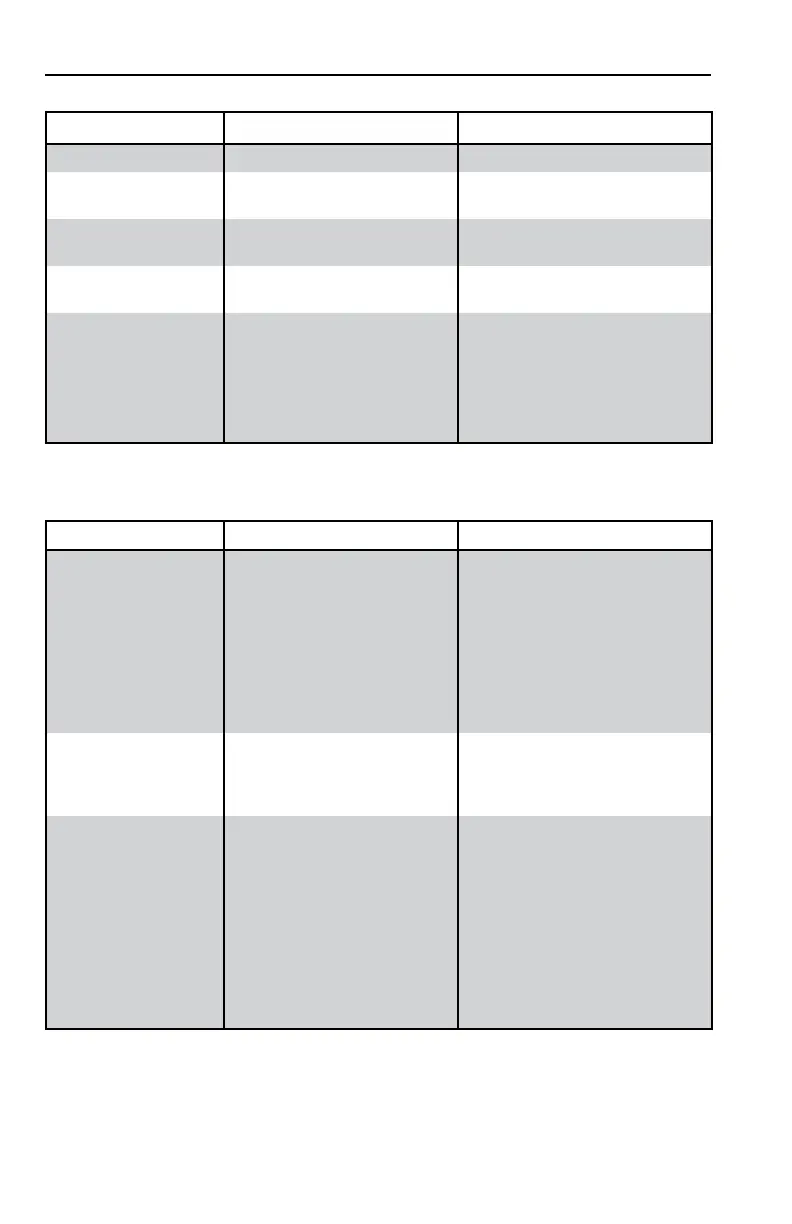

HYDRAULIC PUMP

Problem Cause Solution

Pump noisy

(Cavitation)

a. Low oil supply

b. Thick oil

c. Dirty oil lter

d. Restriction in suction line

e. Pump worn

a. Fill to proper level

b. Fill with proper oil (See chart)

c. Replace lter

d. Clean out and remove

e. Repair or replace

Pump slow or fails to

respond

a. Low oil supply

b. Cold Thick Oil

a. Fill to proper level

b. Drain and rell with a low

temperature oil

Oil heating up a. Foreign material lodged in

relief valve lter

b. Using too light oil

c. Dirty oil

d. Oil level too low

e. Pump worn (slippage)

a. Inspect and remove/replace

b. Drain and rell with clean oil

c. Drain, ush and rell with

clean oil/replace lter

d. Fill to proper level

e. Repair or replace

Loading...

Loading...