9629 Microprocessor Controller

- 13 -

Section IV

Description

The 9629 control is a microprocessor-based

control designed for the control of wire feed,

primarily for TIG and plasma welding. The

9629 is one of a series of controls designed for

ease-of-use and for accurate control of various

drive motors for different weld applications.

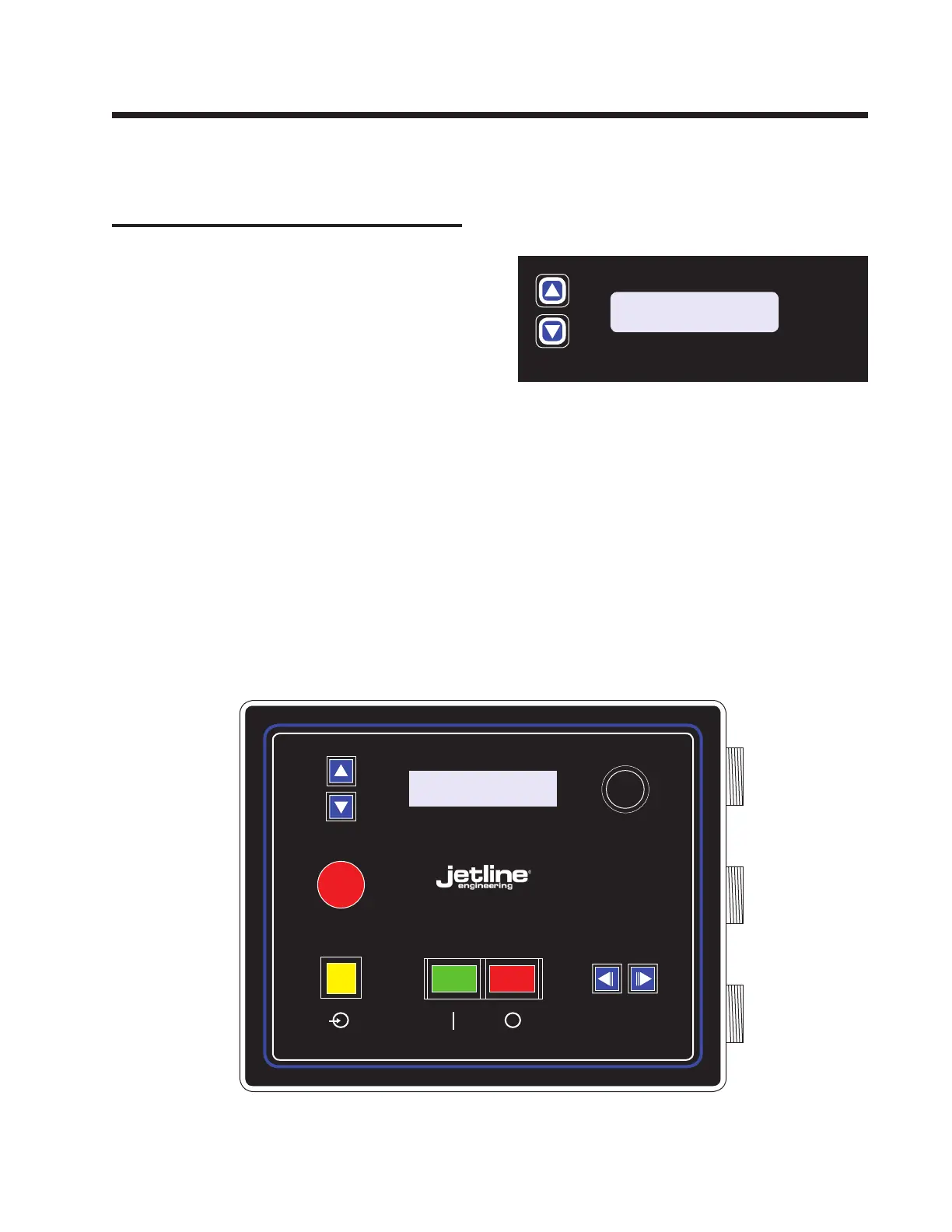

The 9629 is packaged in a conveniently-sized

enclosure with Amphenol connectors. The en-

closure has four mounting holes to permit it to

be fastened to the face of a travel carriage or to a

control podium. The front panel is a membrane

overlay with a backlit LCD display and switches

to control the setup and operation of the unit.

The 9629 control has been designed to be easy

to use. Its operation is made easier by the use of

the display which guides you through the setup

process and, during the welding sequence, tells

you what is happening.

DOWN

UP

WIRE SPEED 26.5ipm

ADJUST

The display has two lines of text, the upper line

is the primary one. This is the line that is used

to set the value of the parameter you are setting.

This is done by calling up the line for the param-

eter required and then turning the adjust knob to

increase or decrease the value. The second line

is used to display status messages (information)

about the progress of the weld sequence to let

you know what stage the process is in. Most of

these messages are normally only displayed after

the start push-button has been pressed.

WIRE SPEED 26.5ipm

SERIES 9600 CONTROL

POWER STOPSTART

REV FOR

UP

DOWN

EMERGENCY

STOP

ADJUST

Loading...

Loading...