SECTION 3 - CHASSIS, PLATFORM & SCISSOR ARMS

3121642 – JLG Lift – 3-5

3.3 DRIVE HUB (FAIRFIELD)

Roll and Leak Testing

Always roll and leak test Drive-Hubs after assembly to make

sure that the unit’s gears and sealants are working properly.

The following information briefly outlines what to look for

when performing these tests.

THE ROLL TEST

The purpose of a roll test is to determine if the unit’s gears are

rotating freely and properly. You should be able to rotate the

gears in your unit by applying a constant

force to the roll

checker. If you feel more

drag in the gears only at certain

points, then the gears are not rolling freely and you should

examine them for improper installation or defects. Some gear

packages roll with more difficulty than others. Do not be con-

cerned if the gears in your unit seem to roll hard as long as

they roll with consistency

THE LEAK TEST

The purpose of a leak test is to make sure the unit is air tight.

You can tell if your unit has a leak if the pressure gauge read-

ing on your air checker starts to fall once you have pressurized

the unit. Leaks will most likely occur at the main seal or wher-

ever o-rings or gaskets are located. Usually you can detect the

exact location of a leak by brushing a soap and water solution

around the main seal and where o-rings or gaskets meet the

exterior of the unit, then checking for air bubbles. If you detect

a leak in a seal, o-ring, or gasket, replace the part immediately.

Tightening and Torquing Bolts

If you use an air impact wrench to tighten bolts, take extreme

care to ensure that you do NOT tighten the bolts beyond their

indicated torque specification. Never

use an impact wrench to

tighten shoulder bolts. Always

tighten all shoulder bolts by

hand.

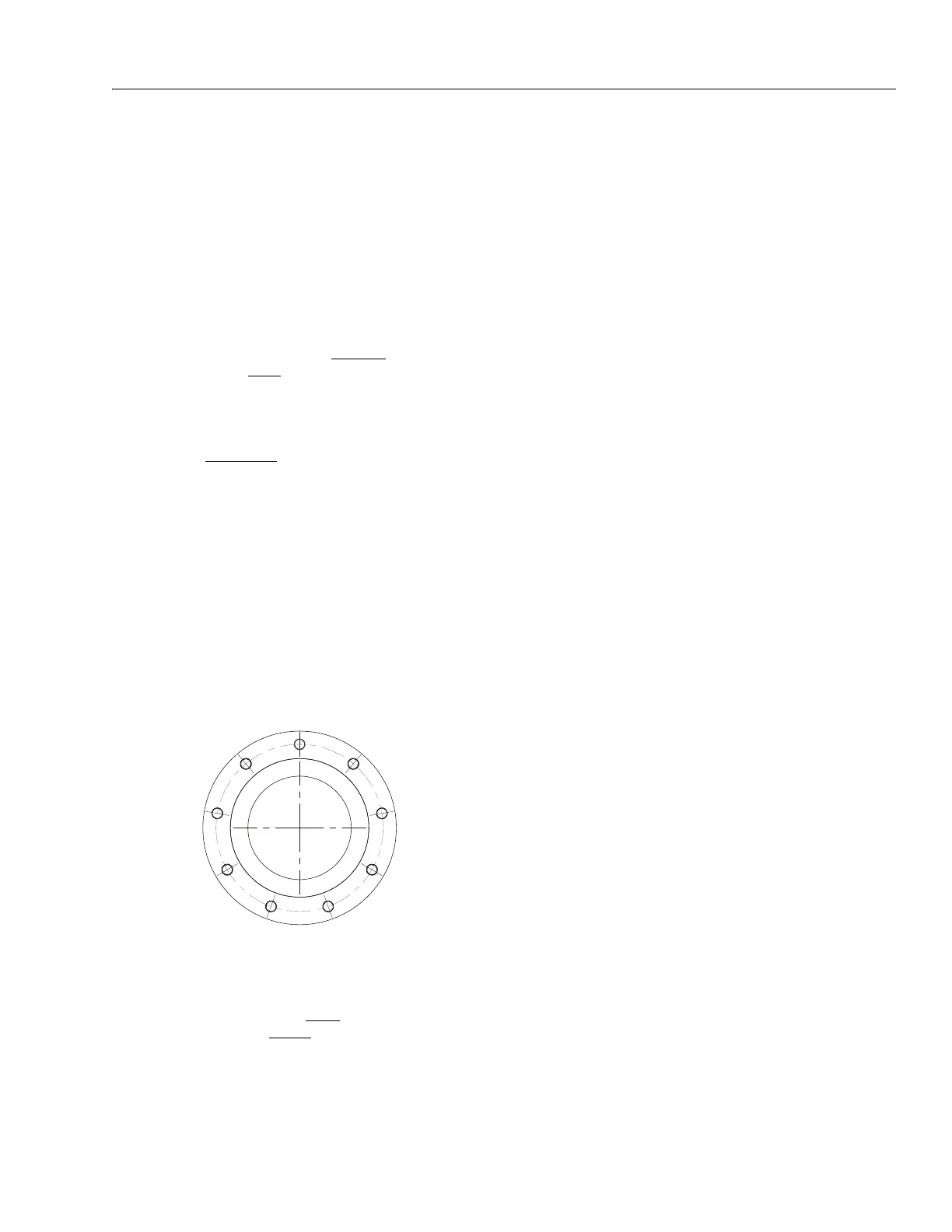

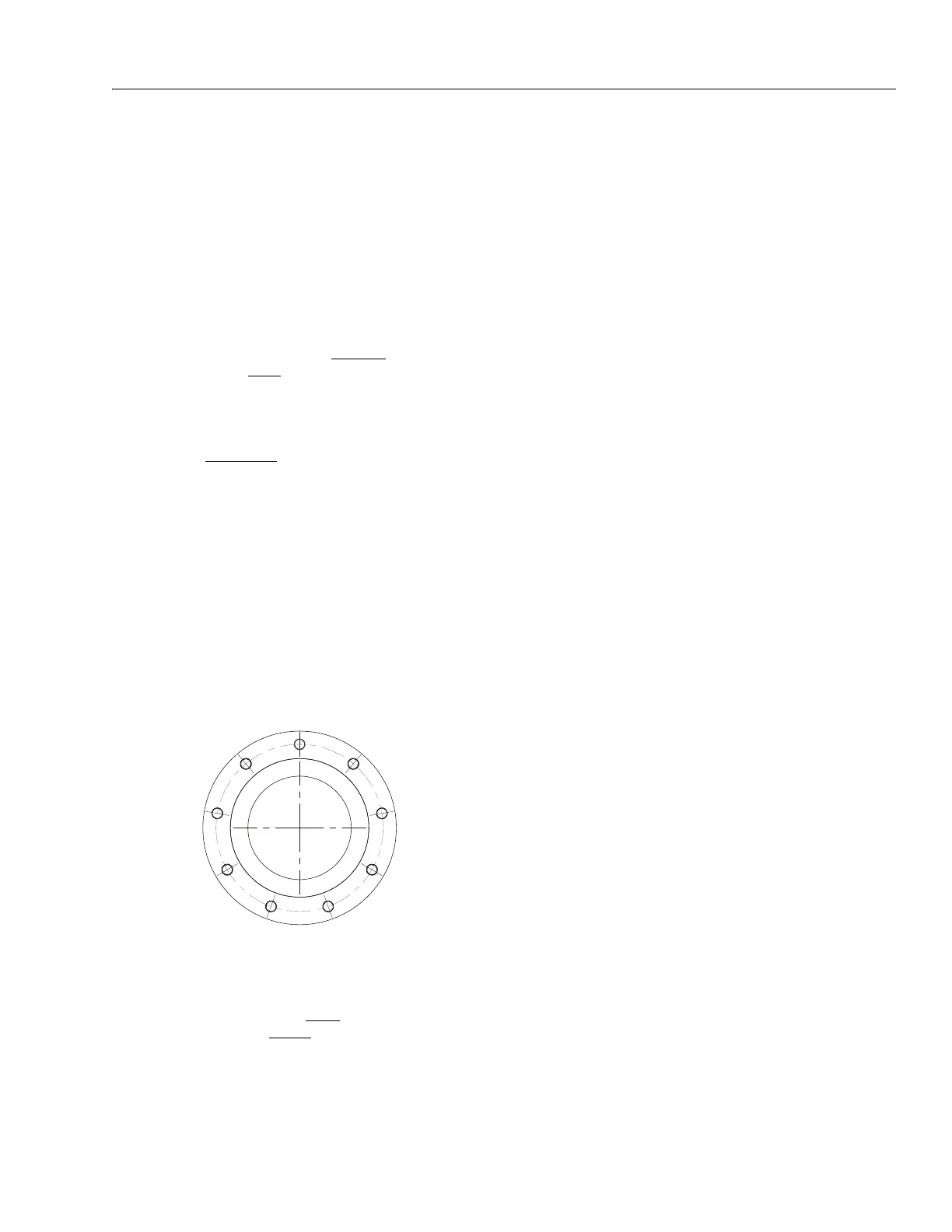

The following steps describe the proper procedure for tighten-

ing and torquing bolts or socket head cap screws in a bolt cir-

cle.

1. Tighten (but do not torque) bolt ”A” until snug.

2. Go to the opposite side of the bolt circle and tighten

bolt ”B” until equally snug.

3. Continue around the bolt circle and tighten the remain-

ing bolts.

4. Now use a torque wrench to apply the specified torque

to bolt ”A”.

5. Continue around the bolt circle and apply an equal

torque to the remaining bolts.

Oil Information

1. TYPE – EP90

On normal applications, use EP90. On applications

where the lubricant must meet special requirements,

the O.E.M. should be able to recommend a suitable sub-

stitute.

2. OIL TEMPERATURE

Continuous – 160°F [70°C] Intermittent – 200°F [95°C]

3. OIL CHANGE

Initial – After 50 hours or 50,000 revolutions of opera-

tion. Subsequent – After 1000 hours or (1) year, which-

ever comes first.

NOTE: Higher temperatures make it necessary to change oil more

frequently.

4. OIL FILL LEVEL AND VOLUME

Unit mounted horizontal – half full

Approximate volume - 17 oz. (0.5 ltr)

5. REAR BRAKES

Rear brakes require 2.7 oz. (0.08 ltr) of DTE 13M hydraulic

fluid each to function properly.

Loading...

Loading...