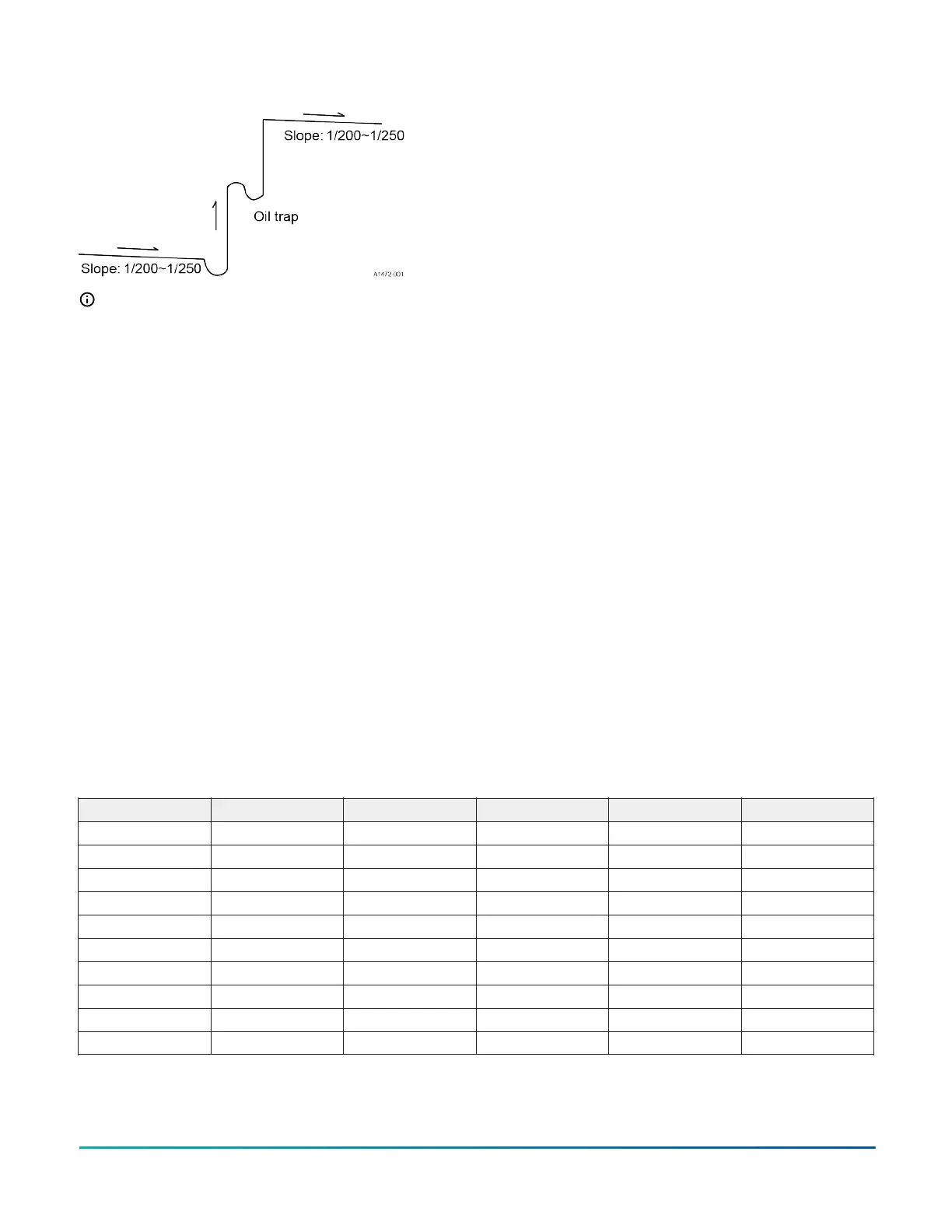

Figure 36: Oil trap

Note:

1. To avoid storing too much oil in the oil trap

and to ensure better cooling and heating

performance, the oil trap must be as short and

as straight as possible.

2. The horizontal piping must slope toward the

trap or outdoor section at a slope of 1/8 in/ft

for proper oil return.

Control mode

Control function

1. Cooling anti-freeze protection: The outdoor

pressure sensors monitor evaporator pressure and

saturated temperature. This feature prevents the

indoor unit evaporator temperature from becoming

too low. If the indoor coil temperature is too low, the

compressor automatically engages protection mode.

2. Overload protection: To prevent system overload

caused by excessive pressure, the control

implements real-time detection when the outdoor

coil temperature is too high during cooling mode

or the indoor coil temperature is too high during

heating mode.

3. Compressor discharge temperature protection:

To prevent damage due to a high compressor

discharge temperature, the control monitors the

discharge gas temperature and provides automatic

protection if the temperature is too high.

4. Oil-return control: When the compressor runs at

low frequencies for a long time, the control initiates

an oil-return sequence to ensure oil is returned to

the compressor.

5. Operation mode: Air conditioning mode is

the operation mode set by users through the

thermostat. Two modes are available: cooling and

heating.

6. Four-way valve control: The four-way valve of

the outdoor unit is de-energized in cooling and

defrosting, and energized in heating. During

heating, the four-way valve is de-energized for a

period of time after the compressor stops.

7. Start-up protection: To prevent frequent

compressor starts where the system pressure has

not equalized, the control invokes a delay of 3 min

between cycles to prevent short cycles.

8. Pressure protection: When the pressure increases

to a preset value, the pressure switch automatically

changes to protection mode. The compressor stops

and reports the protection fault code.

Sensor parameter

These are the parameters for the outdoor compressor discharge sensor:

(R0=187.25K±6.3%, R100=3.77K±2.5K, B0/100=3979K±1%)

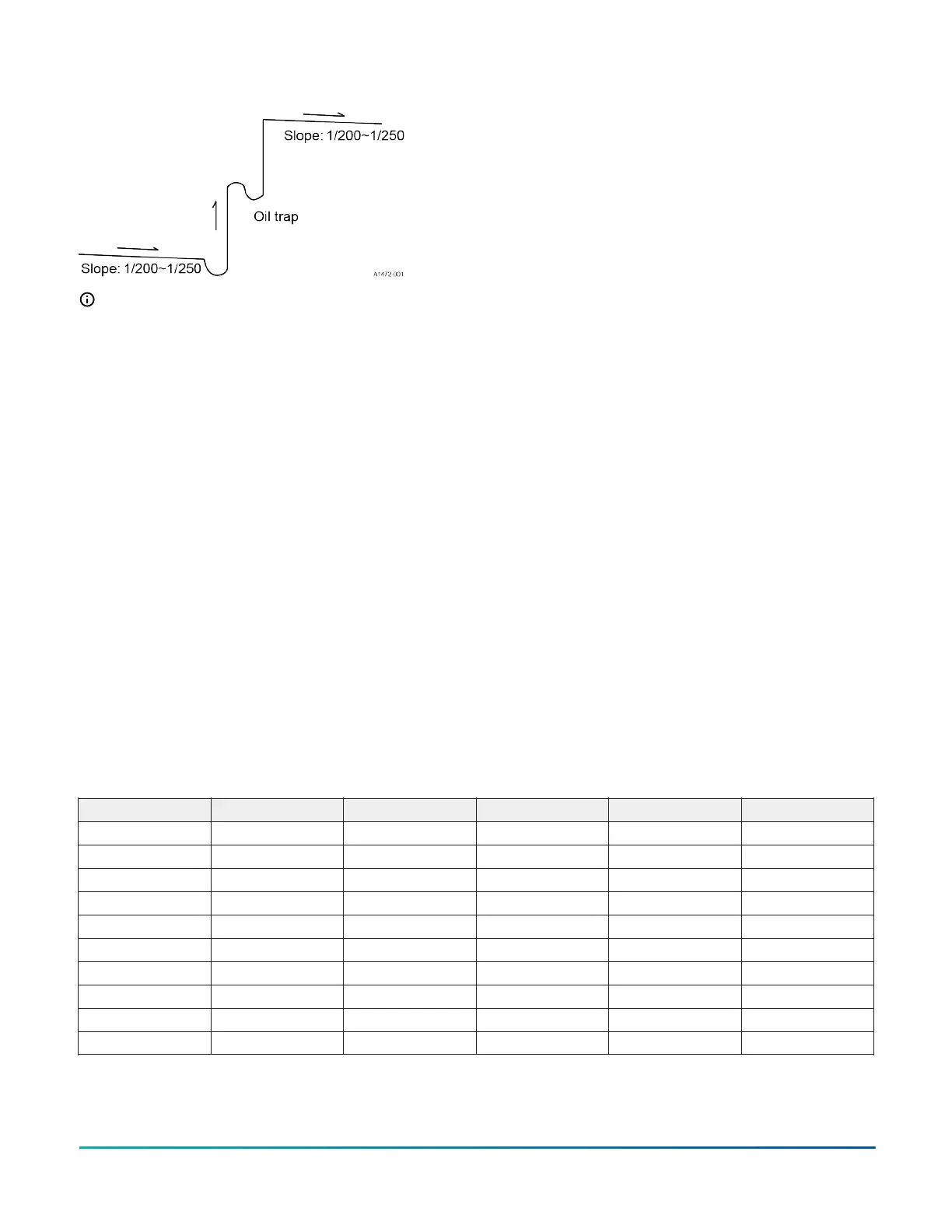

Table 8: Outdoor compressor discharge temperature sensor

T [ ℃ ] Rmin [ KΩ ] Rnom [ KΩ ] Rmax [ KΩ ] Dev(MIN)% Dev(MAX)%

-30 908.2603 985.5274 1065.1210 -7.84 7.47

-15 384.2888 413.3808 442.9105 -7.04 6.67

0 175.4533 187.2500 199.0468 -6.30 5.93

15 85.4114 90.4842 95.5398 -5.61 5.29

30 44.1034 46.4046 48.6960 -4.96 4.71

45 23.9697 25.0632 26.1488 -4.36 4.15

60 13.6400 14.1799 14.7154 -3.81 3.64

75 8.0951 8.3705 8.6440 -3.29 3.16

90 4.9853 5.1292 5.2726 -2.81 2.72

105 3.1632 3.2491 3.3353 -2.64 2.58

These are the parameters for the suction, ambient, coil, and discharge sensors: (R0=15K±2%, B0/100=3450K±2%)

Installation Manual: HMH7 Series - 17 SEER Horizontal Discharge Modulating Heat Pump 31

Johnson Controls Ducted Systems

Loading...

Loading...