M Motor Actuators—M100C Series of Motor Actuators 9

!

CAUTION: Disconnect the electrical power supply before wiring

the motor actuator to avoid possible electrical shock

or damage to the equipment. Always disconnect the

24 VAC power supply before attempting to make any

wiring connections.

Make all wiring connections using copper conductors only. Wire in

accordance with National Electric Code and local regulations.

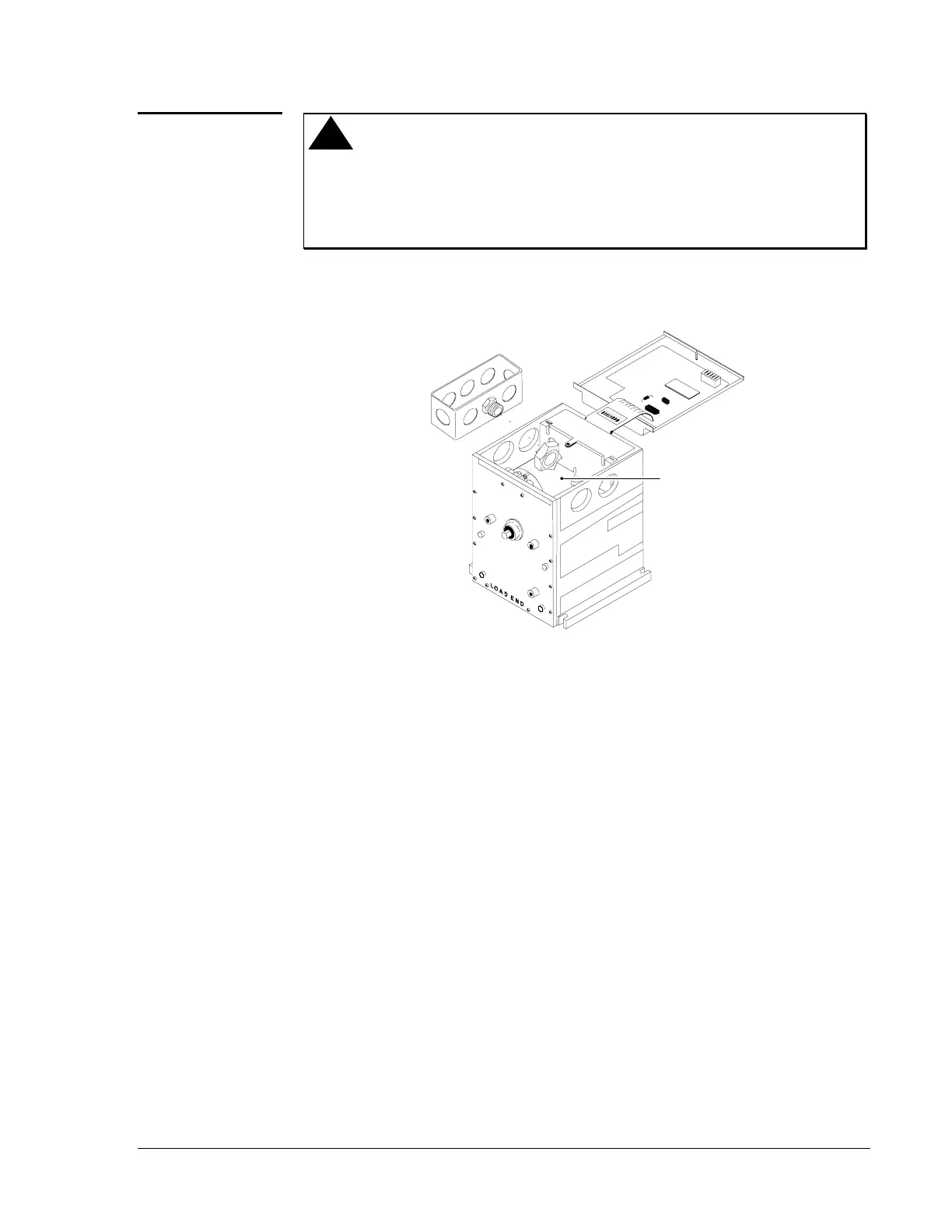

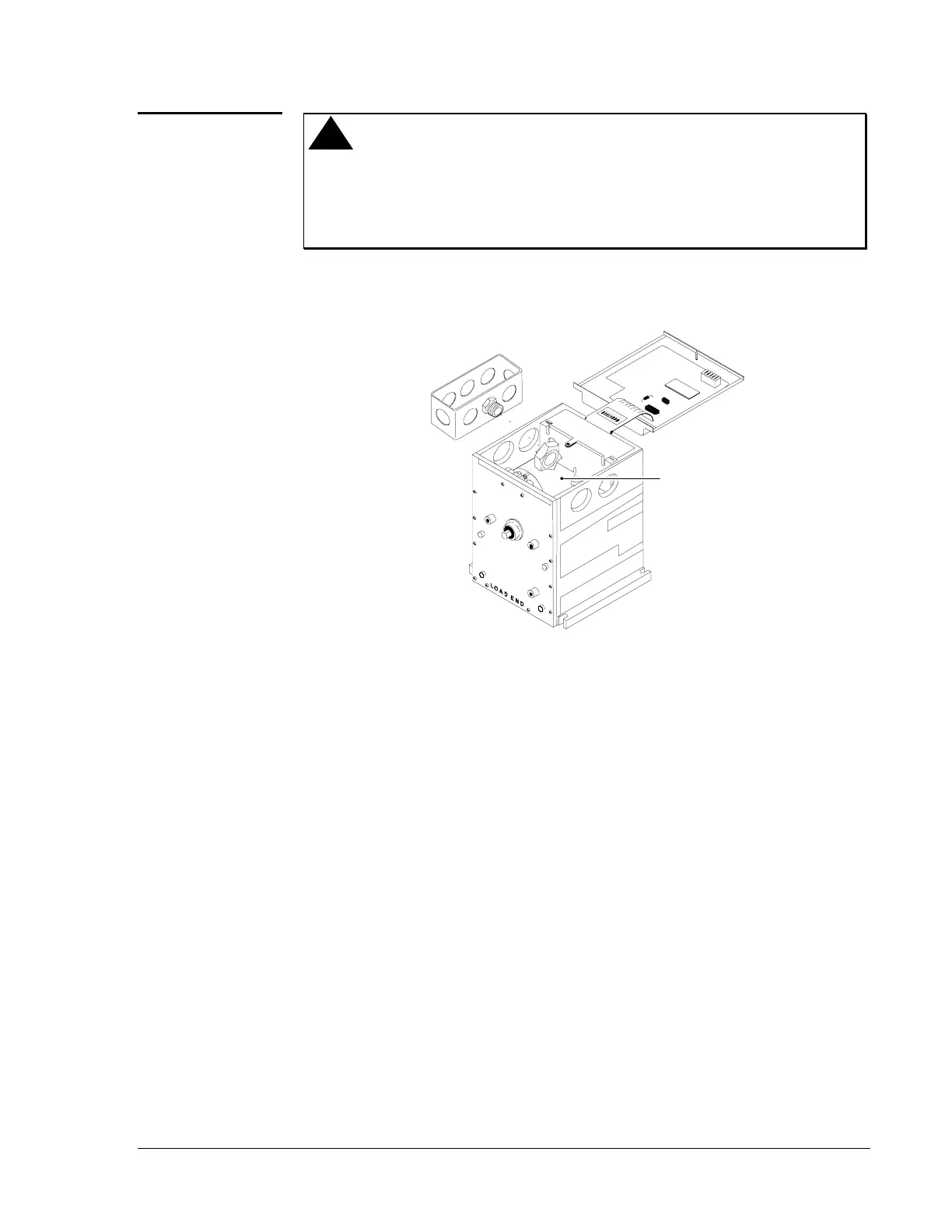

M100C05

Wiring

Compartment

Figure 8: Wiring Junction Box Attached to M100

Make all splices in junction boxes using approved solderless connectors,

or by soldering and then taping the connections. Locate all splicing and

excess wiring outside the motor actuator wiring compartment. If desired,

add a standard electrical box to the wiring compartment of the motor

actuator as shown in Figure 8.

Runs less than 50 feet (15 m) long require no shielded cable. Avoid

running low voltage control wiring in the same conduit pipe as line voltage

wiring or other conductors that supply highly inductive loads (contactors,

coils, motors, generators, etc.).

If the control wiring is over 50 feet (15 m) long, run in a common conduit,

or near inductive loads, the use of shielded cable is recommended. Use 22

AWG gauge, Beldfoil 8761 or equivalent for runs up to 250 feet (76 m).

For 250 feet (76 m) to 500 feet (152 m) runs, use 18 AWG gauge Beldfoil

8760 or equivalent.

Control Wiring

Loading...

Loading...