System 450™ Series Modular Control Systems with Standard Control Modules Technical Bulletin 51

When you supply power to a module assembly, the control module polls all of the

connected modules, detects all of the outputs in the module assembly, then assigns

an output number to each output, and enables an Analog Output Setup Start

(OUTA

x

) screen for each analog output detected (Figure 25 on page 52). See

Analog Outputs on page 20 for more information.

Note: The condition (temperature, pressure, or humidity), unit of measurement,

minimum differential value, default setup values, and condition value

ranges available in the output setup screens are determined by the Sensor

Type of the sensor that you select for the output. See Table 2 on page 16 for

more information on sensors that are compatible with System 450 standard

control modules, their Sensor Types, and the values and ranges associated

with each Sensor Type.

The Setpoint (SP) and End Point (EP) screens allow you to set up a proportional

band (or throttling range) for the control loops in your controlled system.

The Output at Setpoint (OSP) and Output at End Point (OEP) screens allow

you to select the output signal strength (as a percentage of the total signal strength

range) that an analog output sends to the controlled equipment at Setpoint and End

Point.

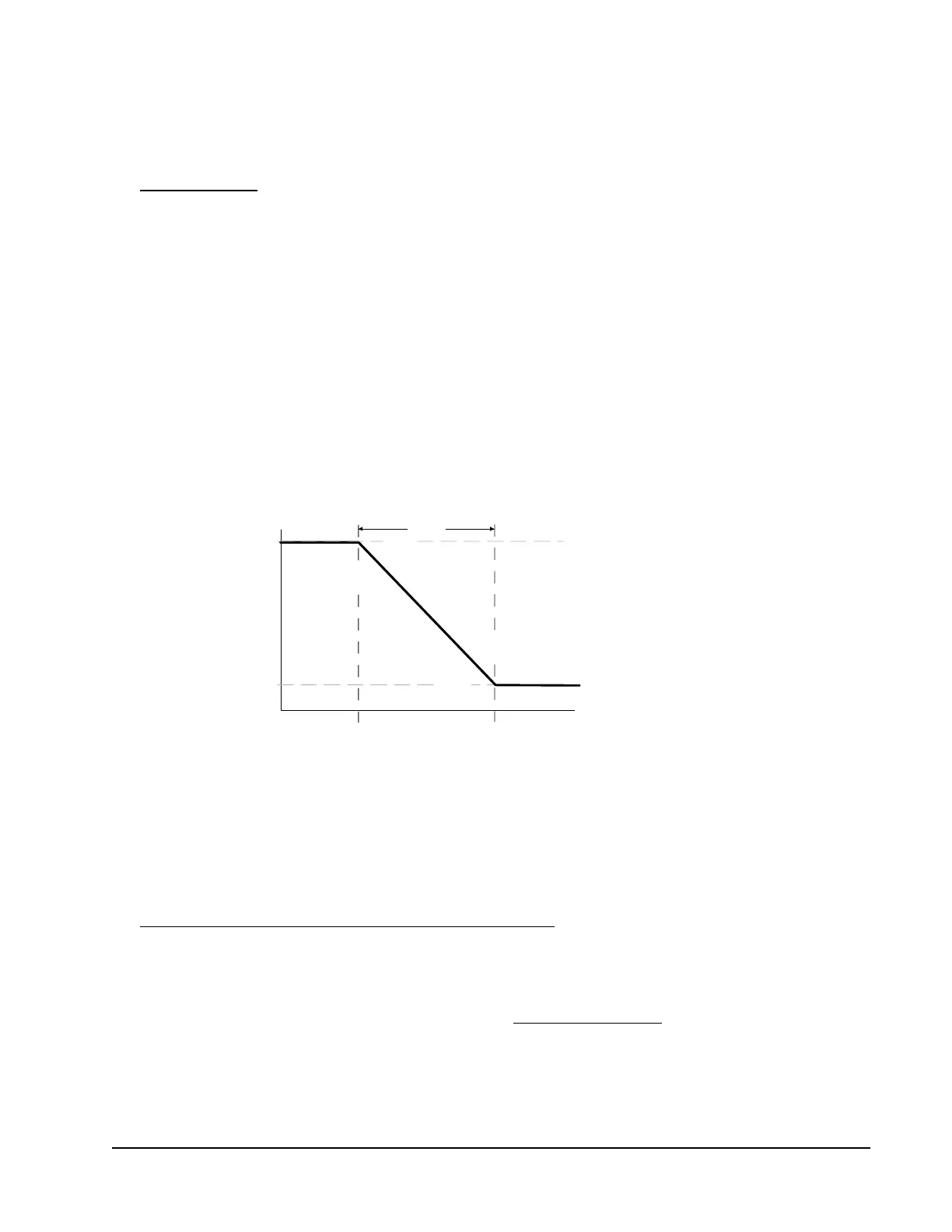

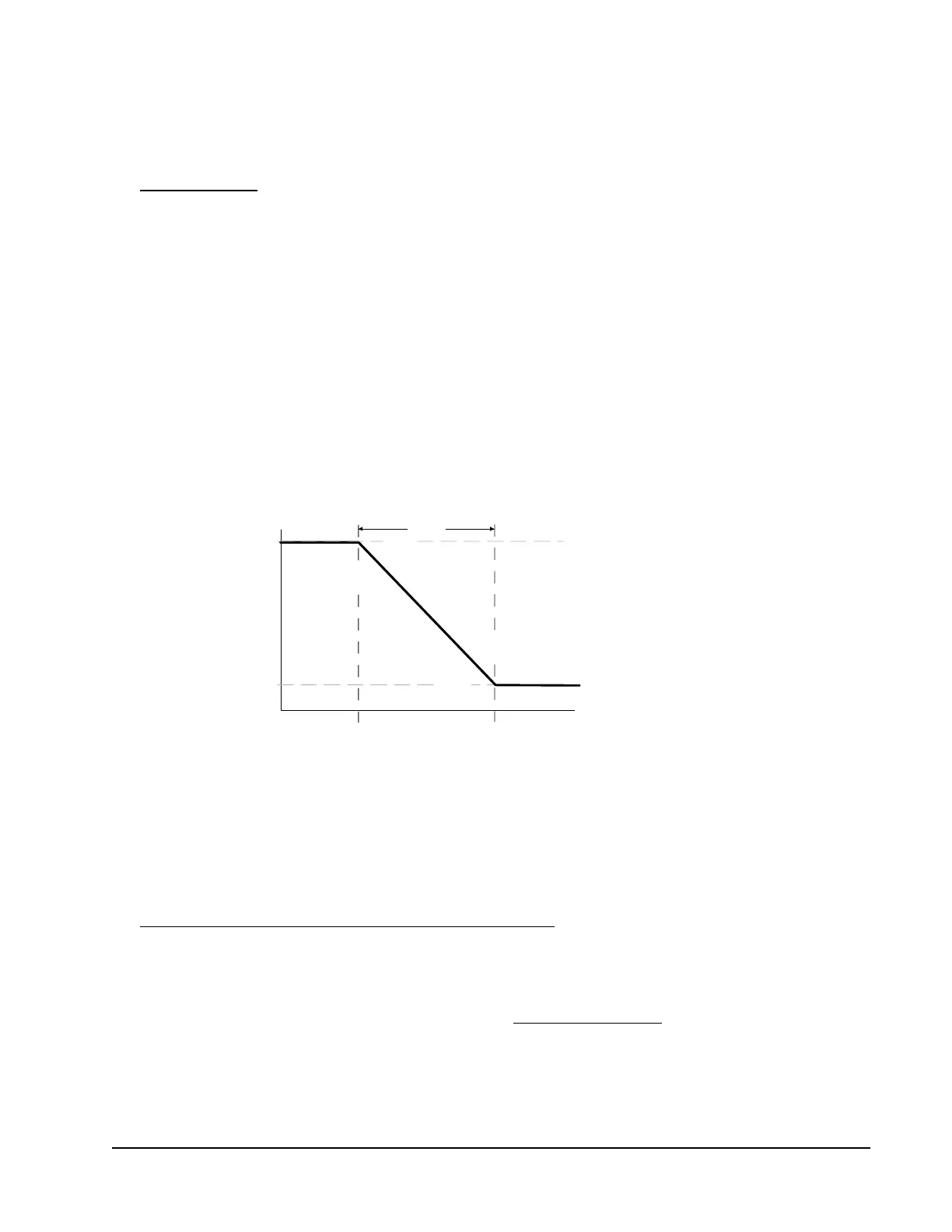

The relationship between these four setup values (SP, EP, OSP, and OEP)

determines the analog output’s proportional control action, which is indicated on

the control module LCD by the control ramp indicator. See Figure 2 on page 10

Direct and Reverse Control Actions for Analog Outputs

on page 20 for more

information.

Note: System 450 analog outputs that reference the differential control sensor

(Sn-d) use a Differential Setpoint (dSP) and Differential End Point (dEP) to

define the output’s proportional band. See Differential Control

on page 25

for more information.

Figure 23: Relationship between Setpoint, End Point, Output at Setpoint,

and Output at End Point for an Analog Output That Controls Room Heating

Condition Value

OSP

SP

EP

Sensor Type =

= 70 ( )

= 65 ( )

>

= 10 (%)

= 100 (%)

SP

EP

SP EP

OSP

OEP

°F

°F

°F

Proportional

Band

Fig:sys450_cntrl_rmp_1

Loading...

Loading...