11. Release the refrigerant charge into the system.

Open the liquid line service valve first. When the

system pressures have equalized, open the vapor

line service valve by removing the valve caps and

turning the valve counterclockwise using a hex

head wrench. If the service valve is a ball valve,

use an adjustable end wrench to turn the valve

stem one-quarter turn counterclockwise to open.

Do not overturn or the valve stem may break or

become damaged. See Precautions during brazing

of service valve.

12. Replace the service valve cap finger tight, then

tighten an additional 1/12 turn (1/2 hex flat). The

cap must be replaced to prevent leaks.

13. See System charge for checking and recording

system charge.

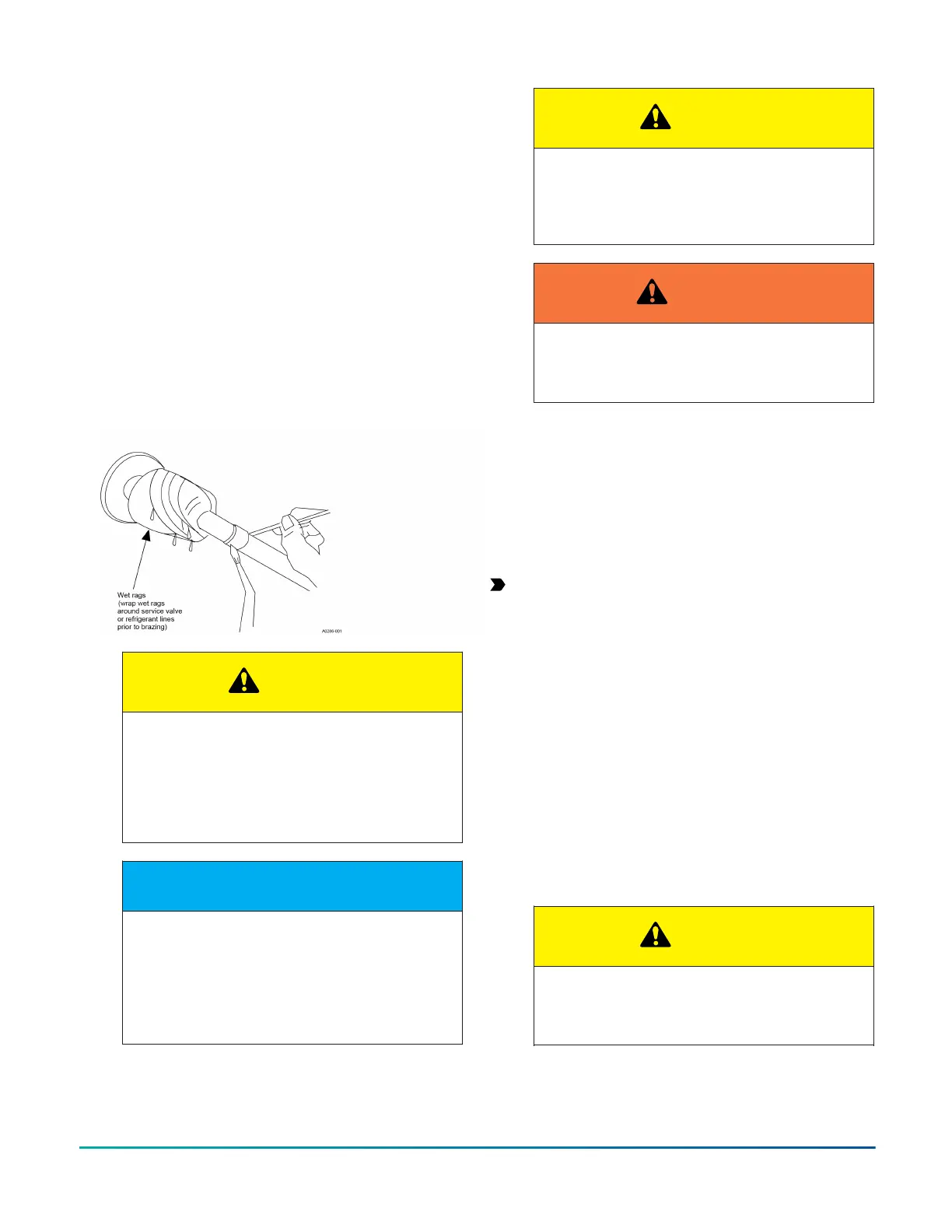

Figure 5: Heat protection

CAUTION

Do not install any coil in a furnace which is to

be operated during the heating season without

attaching the refrigerant lines to the coil. The

coil is under pressure which must be released

to prevent excessive pressure build-up and

possible coil damage.

NOTICE

Line set and indoor coil can be pressurized to

250 psig with dry nitrogen and leak tested with

a bubble type leak detector. Then release the

nitrogen charge.

Do not use the system refrigerant in the

outdoor unit to purge or leak test.

CAUTION

Do not connect manifold gauges unless

trouble is suspected. Approximately 3/4 oz of

refrigerant will be lost each time a standard

manifold gauge is connected.

WARNING

Never attempt to repair any brazed

connections while the system is under

pressure. Personal injury could result.

Indoor expansion device

Installing the thermostatic expansion

valve (TXV)

About this task:

The following are the basic steps for installation. For

detailed instructions, refer to the Installation Manual

accompanying the TXV kit. Install TXV kit as follows:

Important: Refer to the Technical Guide for the

unit to determine the correct TXV kit to use on this

product.

1. Relieve the holding charge by depressing the

Schrader core on the suction manifold stub out.

2. After the holding charge is completely discharged,

loosen and remove the Schrader core.

3. Place a backup wrench on the distributor, then

loosen and remove the brass distributor nut. Retain

the brass nut for use on the liquid line. Keep the

PTFE washer in place and discard the clear disk.

4. Install the TXV to the distributor assembly with the

supplied fittings. Ensure that the PTFE washer is

seated in the distributor. Hand tighten and turn an

additional quarter turn to seal. Do not over-tighten

fittings. See Figure 6.

CAUTION

Do not over-torque. Do not use slip joint pliers.

This will distort the aluminum distributor and

the brass fitting (potentially causing leaks).

Installation Manual: R-410A Outdoor Split-System Heat Pump - YH2F, THF2, RHP150 Series 11

Johnson Controls Ducted Systems

Loading...

Loading...