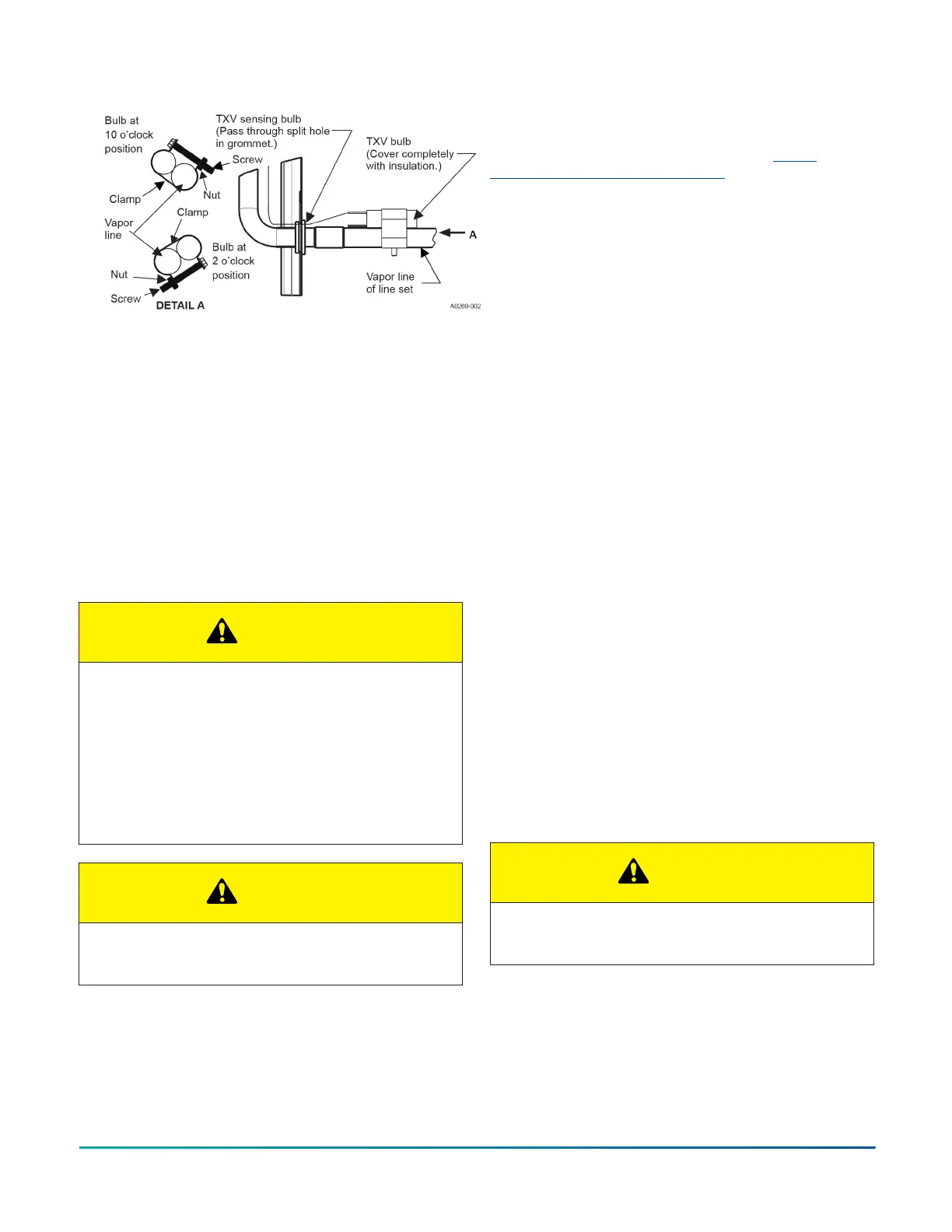

Figure 8: Correct bulb location

Evacuation

Evacuate the system to 500 microns or less. If a leak is

suspected, leak test with dry nitrogen to locate the leak.

Repair the leak and test again.

To verify that the system has no leaks, close the valve to

the vacuum pump suction to isolate the pump and hold

the system under vacuum. Watch the micron gauge for

a few minutes. If the micron gauge indicates a steady

and continuous rise, it is an indication of a leak. If the

gauge shows a rise, then levels off after a few minutes

and remains fairly constant, it is an indication the system

is leak free but still contains moisture and may require

further evacuation if the reading is above 500 microns.

System charge

CAUTION

If a field-installed device is placed in the inner-

connecting refrigerant lines that can store a significant

refrigerant charge (for example, a refrigerant mass

flow meter or a liquid receiver), the unit may not

perform as designed. If such a performance-affecting

device is installed and it is possible to check the

unit in heating mode, the unit pressures should be

confirmed in heating mode. See the heating charging

charts located in this installation manual.

CAUTION

Refrigerant charging should only be carried out by a

licensed qualified air conditioning contractor.

To ensure that the unit performs at the published levels,

it is important to determine the indoor airflow and add

refrigerant charge accordingly.

Measuring indoor airflow

About this task:

To determine the rated airflow for a specific match,

refer to the technical literature available at http://

www.simplygettingthejobdone.com. When attempting to

match this airflow, select the lowest possible speed tap,

measure the actual flow, and adjust as necessary.

To measure actual airflow, it is not an acceptable method

to just check the jumper pin setting tables and assume 0.5

in. W.C total external static pressure.

To determine indoor airflow, follow these steps:

1. On a gas furnace or single-piece air handler,

measure the static pressure with a manometer

between the filter and return air opening of the

indoor equipment. On a modular air handler,

measure the return air static pressure between the

indoor coil and entering air side of the modular air

handler.

2. Perform a or b.

a. On a single-piece or modular air handler, take a

second reading in the supply air ductwork leaving the

indoor equipment.

b. On a gas furnace, take a second reading after the heat

exchanger, but before the indoor coil.

3. Add the negative return static to the positive

supply static to determine the total system static

pressure. Treat the negative return static as a

positive pressure (even though it is a negative

reading). If there is static pressure on the blower

return (for example, -0.1 in. W.C.), add it to a supply

static (0.4 in. W.C.) that equals the total system

static pressure (0.5 in. W.C.).

4. Compare this value to the indoor blower

performance charts, ensuring air flow is between

350 CFM to 450 CFM per ton of cooling.

Charging the unit

CAUTION

Always charge in liquid form. Take care not to slug the

compressor.

The factory charge in the outdoor unit includes enough

charge for the unit, 15 ft (4.6 m) of refrigerant piping, and

the smallest indoor coil or air handler match-up. Some

indoor coil or air handler matches may require additional

charge.

Installation Manual: R-410A Outdoor Split-System Heat Pump - YH2F, THF2, RHP150 Series 13

Johnson Controls Ducted Systems

Loading...

Loading...