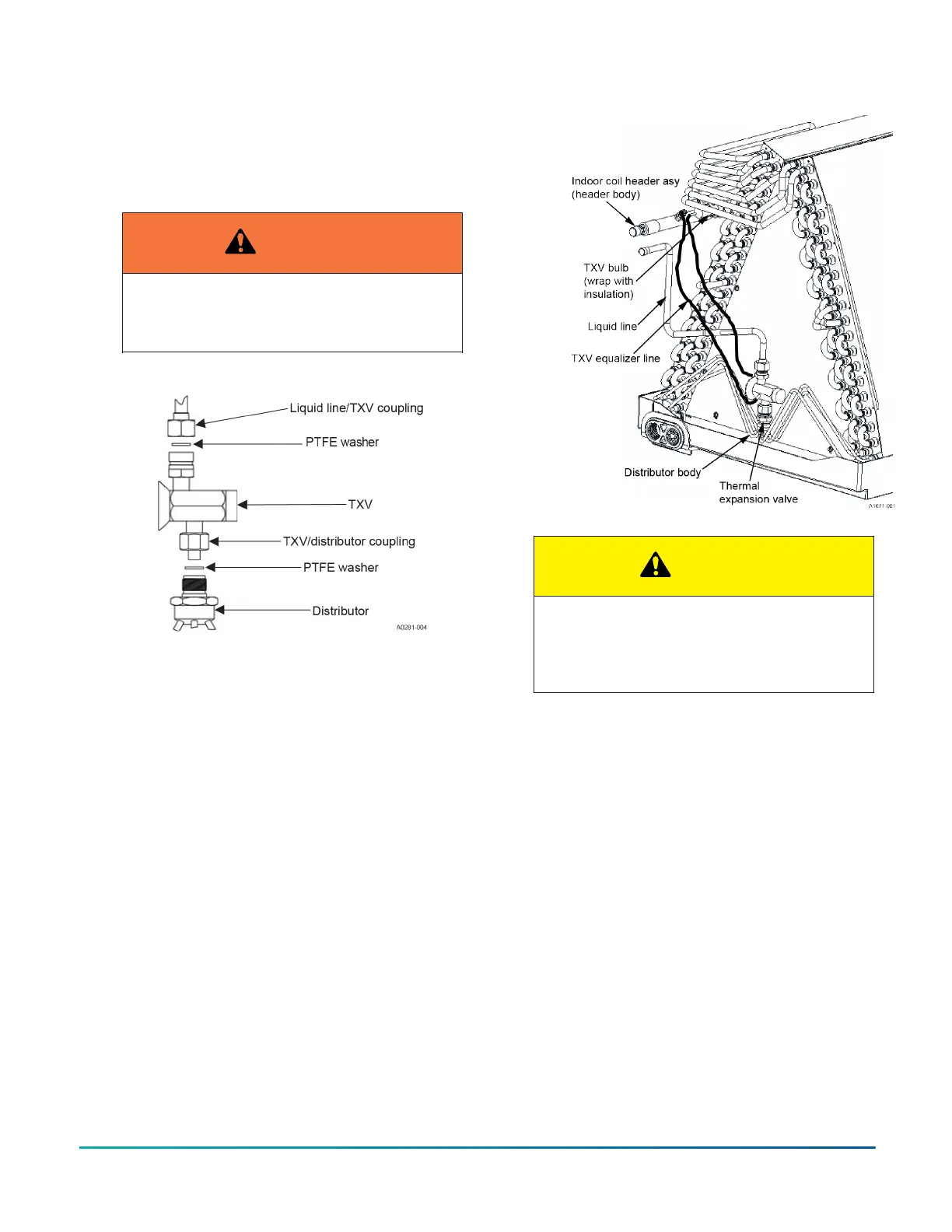

5. Slide the nut removed in Step 3 over the supplied

liquid line. Place the supplied PTFE washer from

the TXV kit on the TXV, and install liquid line to the

top of the TXV. Adjust assembly so liquid line aligns

with hole in access panel. Hand tighten the liquid

line, and apply an additional quarter turn to seal.

WARNING

Schrader valve core must not be installed with

TXV installation. Poor system performance or

system failure could result.

Figure 6: TXV installation

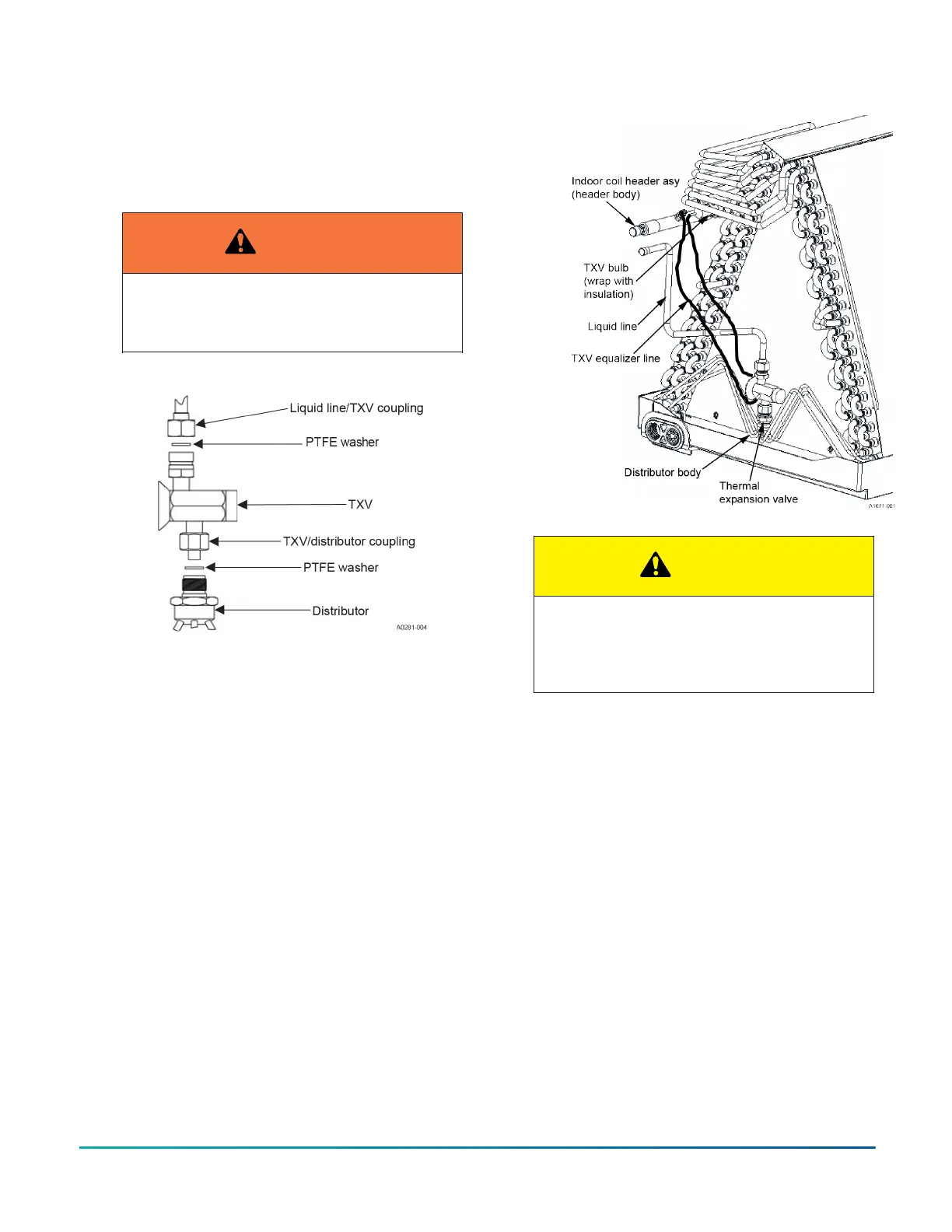

6. Install the TXV equalizer line onto the vapor line by

hand tightening the 1/4 in. SAE coupling nut to the

equalizer fitting, and applying an additional third

turn to seal. See Figure 7.

Figure 7: TXV bulb and equalizer line installations

CAUTION

In all cases, mount the TXV bulb after vapor

line is brazed and has had sufficient time to

cool. Failure to use suction line grommet may

result in premature TXV failure.

7. If the indoor coil is an A coil, skip to Step 8. If not,

pass the TXV temperature sensing bulb through

the suction line split grommet in the access panel.

8. Install the TXV bulb to the vapor line using the bulb

clamps furnished with the TXV assembly. Ensure

the bulb is making maximum contact. See Figure 7

and Figure 8.

a. If possible, install the temperature bulb on a

horizontal run of the vapor line. Ensure that

the bulb is installed at a 10 o’clock or 2 o’clock

position. See Figure 8.

b. If bulb installation is made on a vertical run,

ensure that the bulb is a minimum of 8 in. (20.3

cm) away from the elbow coming out of the

coil. Position the bulb with the tail of the bulb

at the top, so that the bulb acts as a reservoir.

c. Insulate the bulb using thermal insulation

provided to protect it from the effect of the

surrounding ambient temperature. Cover

completely to insulate.

9. After line set is installed, leak test the system.

Installation Manual: R-410A Outdoor Split-System Heat Pump - YH2F, THF2, RHP150 Series12

Johnson Controls Ducted Systems

Loading...

Loading...