Engineering manual - SAB 193-233-283 S A-frame (including ATEX)

60/168

008831 en 2020.10

Technical description

liquid/vapour mixture, which rises to the receiver, dropping out the remaining liquid before allow-

ing the vapour to return to the condenser, completing the cycle.

Piping arrangement for thermosyphon oil cooling systems

The components and piping of a thermosyphon oil cooling system include a liquid source at con-

densing pressure, adequate static heads to provide fluid flow, appropriate control valves, safety

relief valves, service valves and pump-out connections. The arrangement of component place-

ment and fluid flow requirements must be designed to suit the individual refrigeration system lay-

out with consideration given to piping safety practices.

The component and piping arrangement in Fig. 37 is intended only to illustrate the operating prin-

ciples of thermosyphon oil cooling. Other component layouts may be better suited to a specific in-

stallation. For additional information on Thermosyphon Oil Cooling, please refer to Frick

publication 070.900-E.

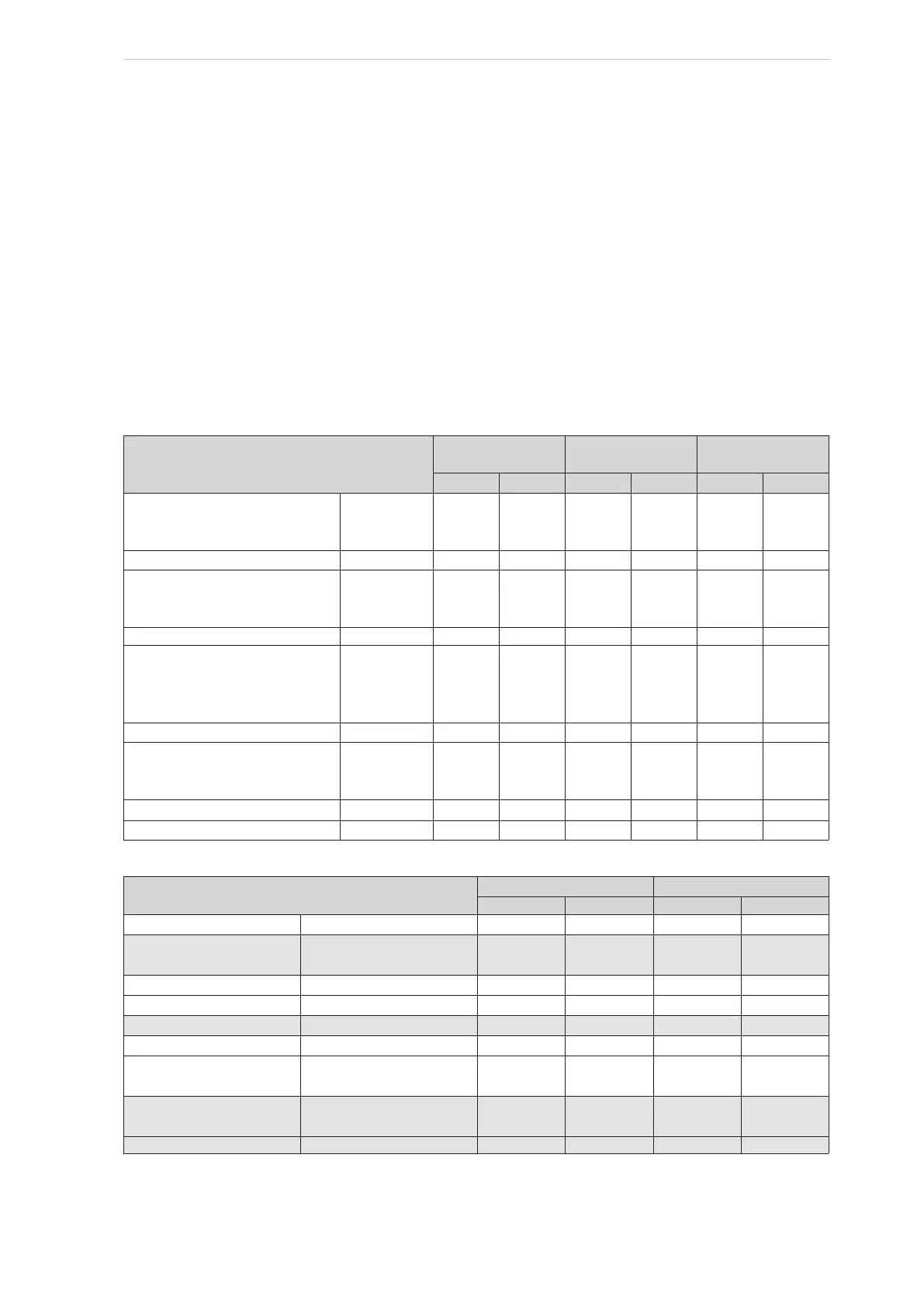

Unit

Type of cooler Inlet Outlet

Type

Plates

Water

Refri.

Water

Refri.

SAB 193 S, L High-stage

3HH

116

66

34

DN80

DN50

DN50

DN80

DN50

DN50

DN80

DN50

DN50

DN80

DN50

DN50

SAB 193 S, L

Booster

3HH 34 DN50 DN50 DN50 DN50

SAB 233 S

High-stage

3HH

116

66

34

DN80

DN50

DN50

DN80

DN50

DN50

DN80

DN50

DN50

DN80

DN50

DN50

SAB 233 S

Booster

3HH 34 DN50 DN50 DN50 DN50

SAB 233 L, E High-stage

3HH

146

116

66

34

DN100

DN80

DN50

DN50

DN80

DN80

DN50

DN50

DN80

DN80

DN50

DN50

DN100

DN80

DN50

DN50

SAB 233 L, E

Booster

3HH 34 DN50 DN50 DN50 DN50

SAB 283 S, L, E, X High-stage

3HH

146

116

34

DN100

DN80

DN50

DN80

DN80

DN50

DN80

DN80

DN50

DN100

DN80

DN50

SAB 283 S, L, E, X

High-stage

4HH

120 DN100 DN100 DN100 DN100

SAB 283 S, L, E

Booster

3HH 34 DN50 DN50 DN50 DN50

Table 7: Oil cooler data

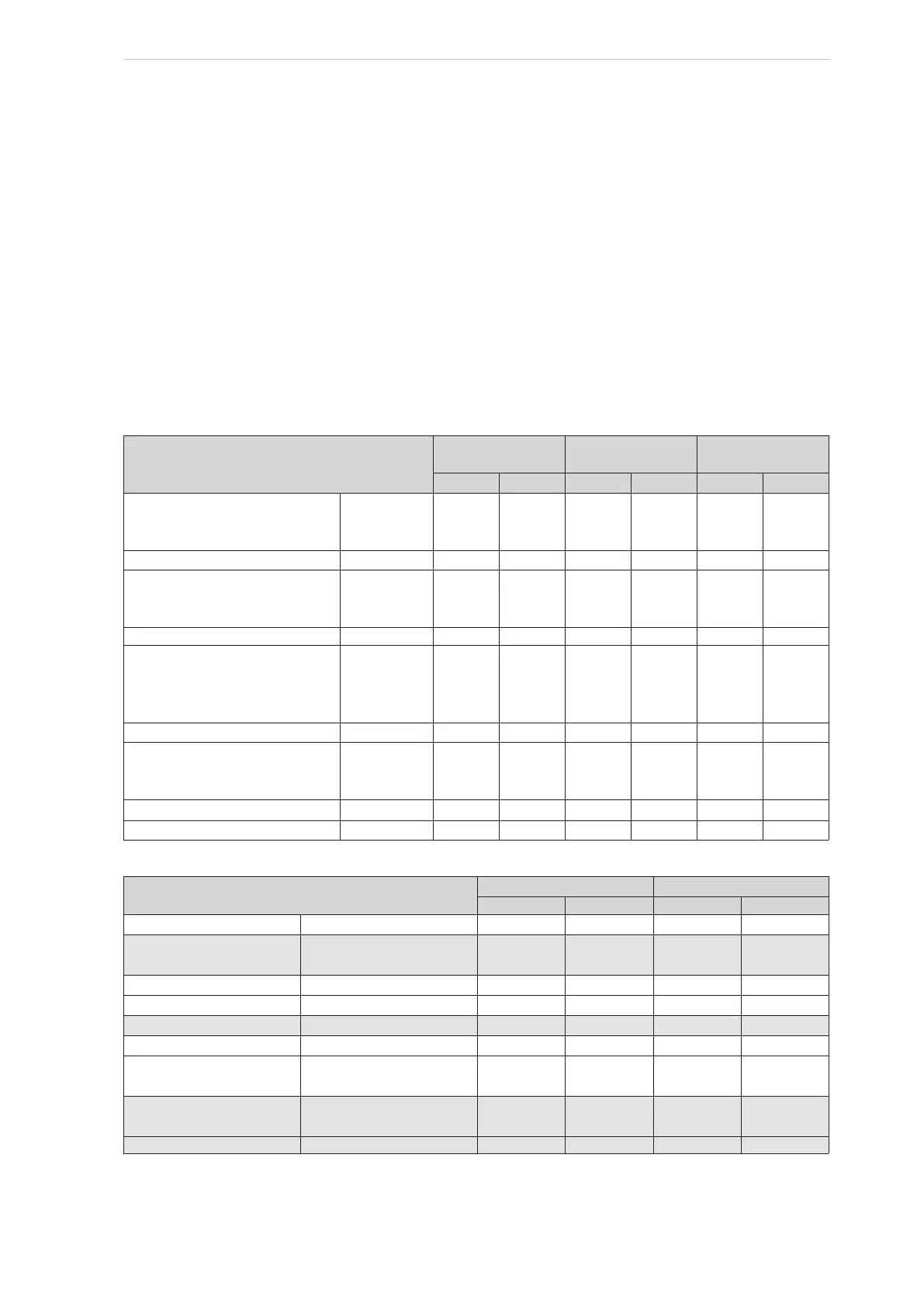

Unit

Type of cooler Connection

Dia. Plates Inlet Outlet

SAB 193 S, L

High-stage

14 in. 116 3 in. 3 in.

SAB193 S, L and SAB

233 S, L, E

Booster 14 in. 66 2 in. 2 in.

SAB 233 S, L

High-stage

14 in. 190 3 in. 3 in.

SAB 233 E

High-stage

14 in. 288 3 in. 4 in.

SAB 283 S, L

Booster

24 in. 56 3 in. 3 in.

SAB 283 S, L

High-stage

24 in. 136 4 in. 5 in.

SAB 283 E, X and SAB

355 S, L

High-stage

24 in. 188 4 in. 5 in.

SAB 283 E, X and SAB

355 S, L, E

Booster

24 in. 72 3 in. 3 in.

SAB 355 X

Booster

24 in. 136 4 in. 5 in.

Table 8: Oil cooler data

Loading...

Loading...