Notes:

• Prior to performing this procedure, be sure the

controller has been converted from BACnet to N2

protocol first. Refer to the Modernization Guide for

Legacy N2 Controllers (LIT-12012005) for more

information.

• This special configuration is required because

controller addresses above 127 were originally

intended for use with the Wireless Field Bus system.

1. Disconnect the 24 VAC supply from the controller.

2. Remove the FC Bus connector from the controller.

3. Set the address switch set to the desired N2 address.

4. Set the address switch segment labeled 128 to OFF.

5. Reconnect the 24 VAC supply to the controller.

6. Using an SA bus connection, download the firmware

and controller application file. The download process

asks to confirm switching the communication protocol

to N2.

7. Click OK.

8. After the download is finished, disconnect the 24

VAC supply to the controller.

9. Set the address switch segment labeled 128 to ON.

10. Reattach the FC Bus connector to the controller.

11. Reconnect the 24 VAC supply to the controller.

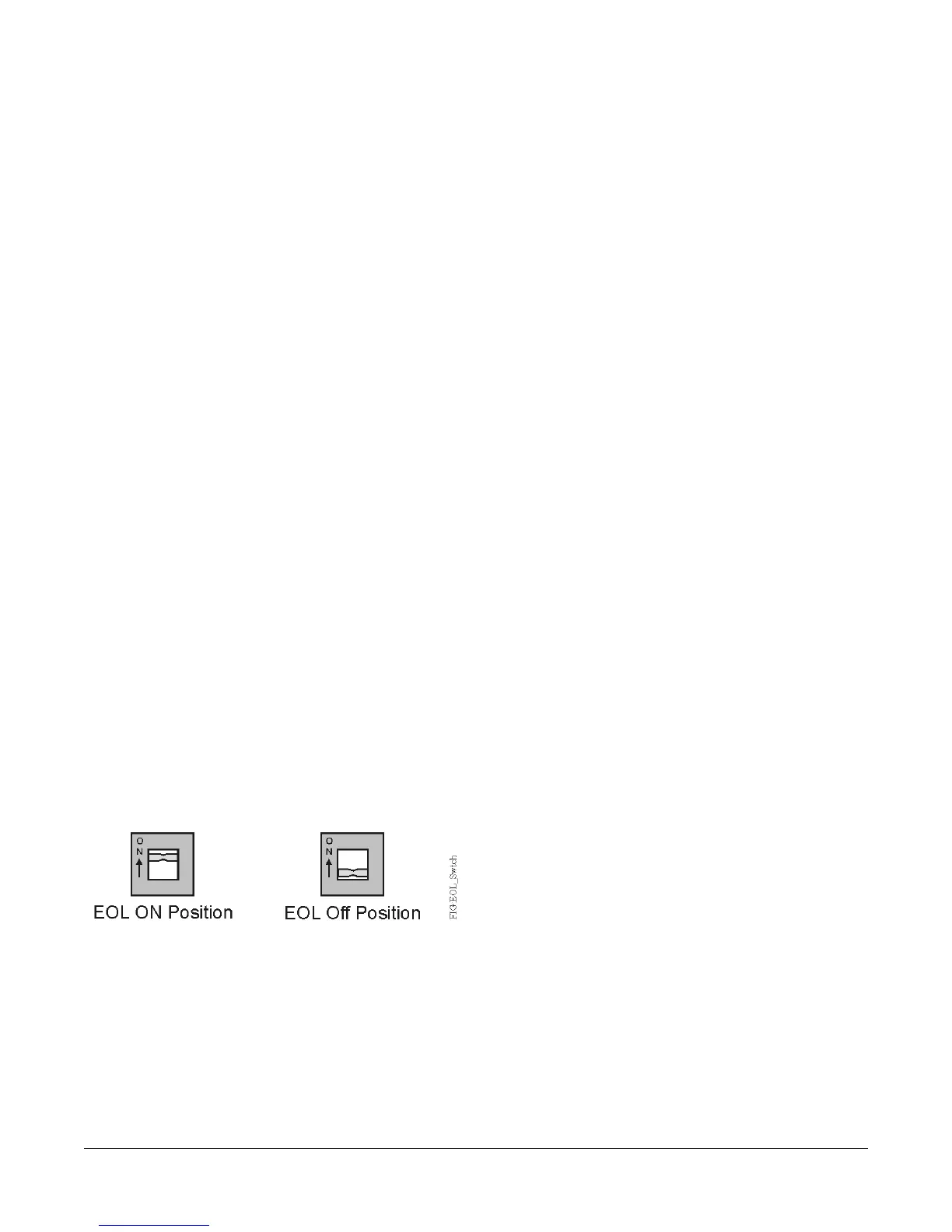

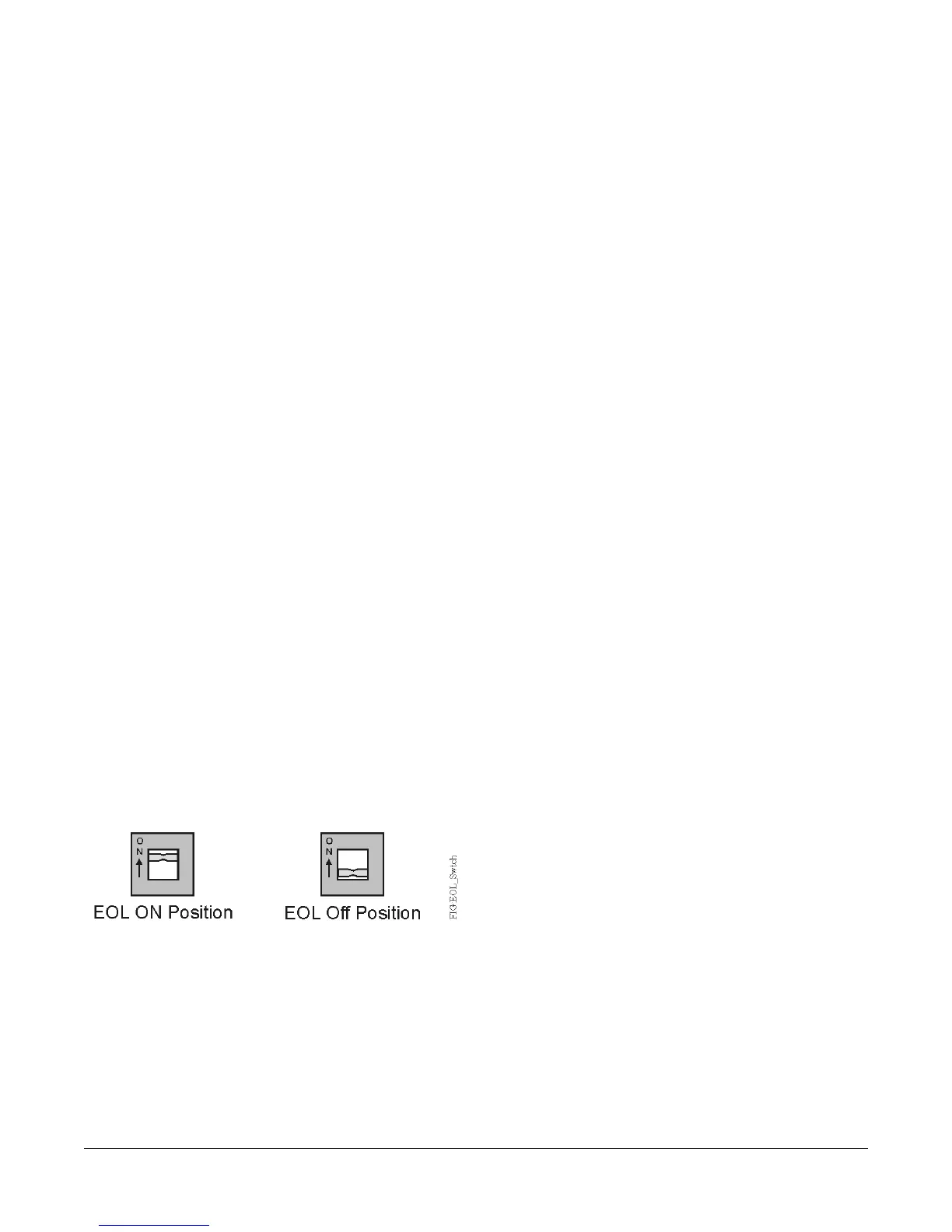

Setting the EOL Switch

Each field controller has an EOL switch, which, when set

to ON (up), sets the field controller as a terminating device

on the bus. See Figure 2 for the EOL switch location on

the field controller. The default EOL switch position is

OFF (down). The amber EOL LED illuminates to show

the EOL is active.

Figure 10: EOL Switch Positions

To set the EOL switch on a field controller:

1. Determine the physical location of the controller on

the SA or FC Bus.

2. Determine if the controller must be set as a

terminating device on the bus.

Note: The EOL termination rules for SA Buses and

FC Buses are different. Refer to the MSTP

Communications Bus Technical Bulletin

(LIT-12011034) for detailed information

regarding EOL termination rules and EOL

switch settings on SA and FC Buses.

3. If the controller is a terminating device on the FC Bus,

set the EOL switch to ON. If the controller is not a

terminating device on the bus, set the EOL switch to

OFF.

Note: When the EOL switch is set to ON, the LED

light on the face of the controller is illuminated.

Commissioning

Use the following procedure to commission the

VMA1615/1626/1628/1630 controller:

1. Download the control application to the VMA controller

using the Controller Configuration Tool (CCT). Refer

to the Controller Tool Help (LIT-12011147).

2. Commission the VAV Box. Refer to the Controller

Tool Help (LIT-12011147).

3. Perform airflow balancing on the VAV box. Refer to

the VAV Balancing Tool Technical Bulletin

(LIT-12011087).

4. Perform commissioning checkout procedures. Refer

to the Controller Tool Help (LIT-12011147).

The CCT connects to the VMA through a laptop computer

using different connection options: the Wireless

Commissioning Converter, or the wired BACnet Ethernet

to MS/TP Router can be used when using the BACnet

MS/TP protocol. When the controller is configured to use

the N2 protocol, you must use the Commissioning

Converter at the SA bus. Wireless connections are not

supported in N2 mode. These connection options require

additional hardware listed in Table 10.

Repair Information

If the VMA1615/1626/1628/1630 controller fails to operate

within its specifications, replace the unit. For a

replacement unit, contact the nearest Johnson Controls

representative.

Troubleshooting

Table 9 provides LED status indicator information for

troubleshooting the VMA1615/1626/1628/1630 controller.

17VMA1615/1626/1628/1630 VAV Controllers Installation Instructions

Loading...

Loading...