JOHNSON CONTROLS

195

FORM 150.62-NM6 (103)

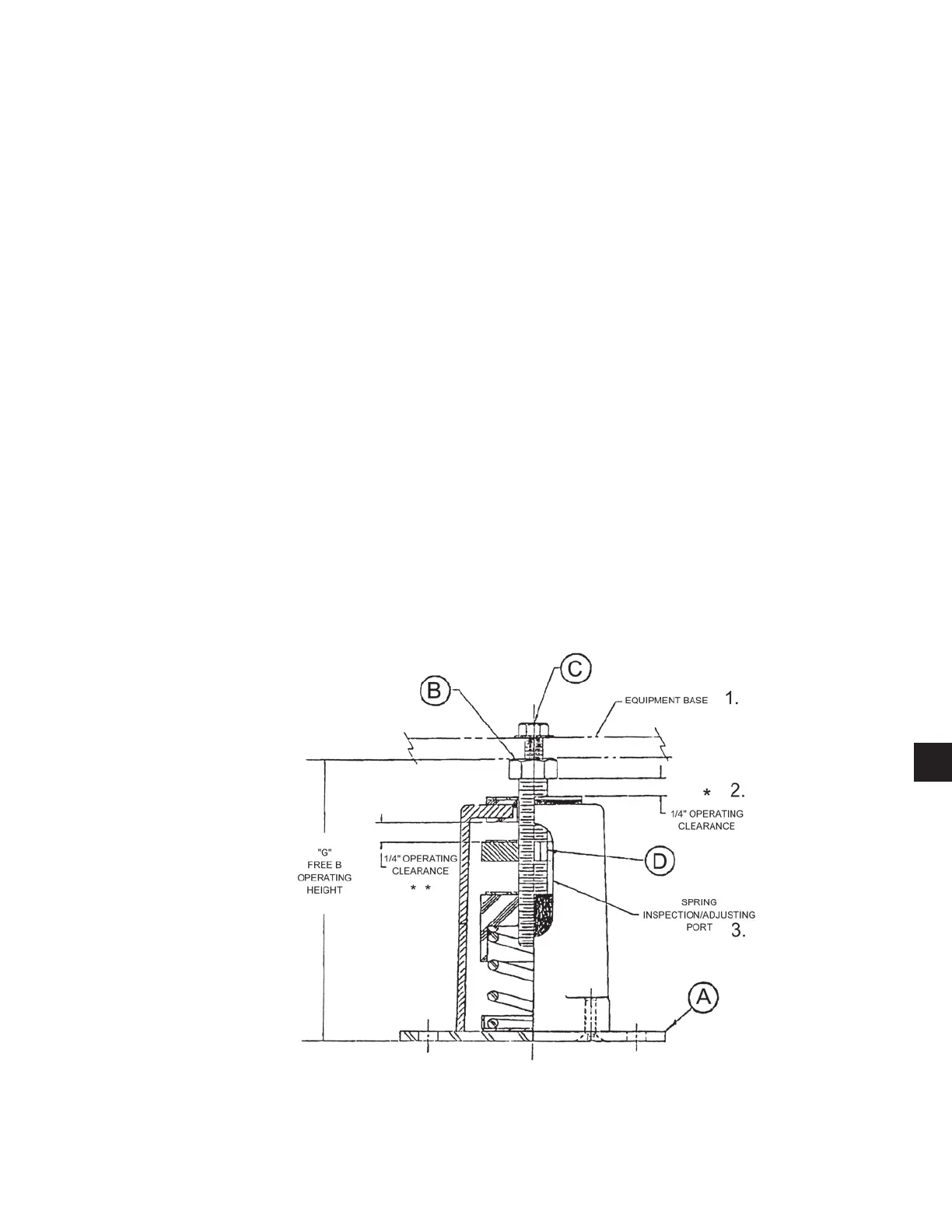

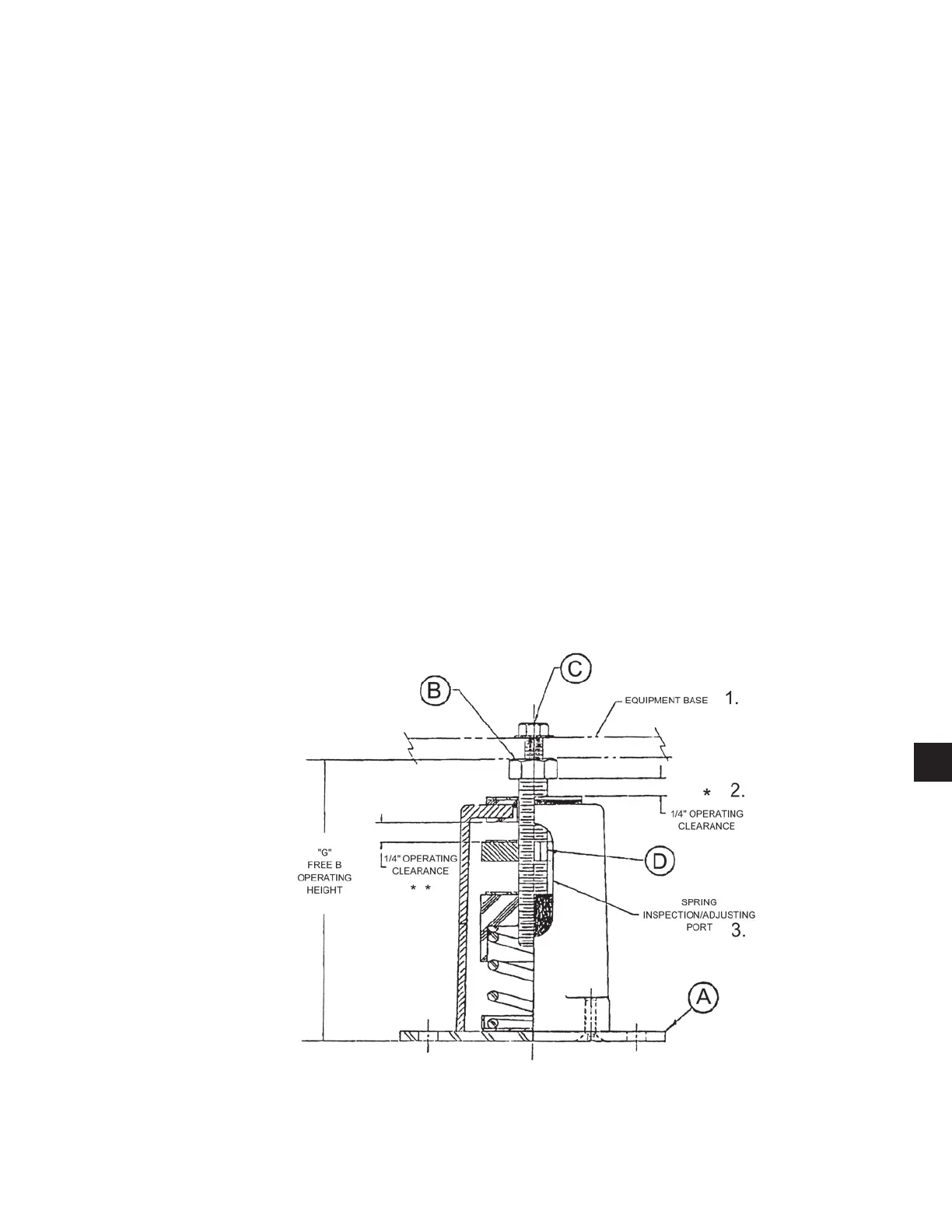

“AEQM” SPRING-FLEX MOUNTING

INSTALLATION AND ADJUSTMENT INSTRUCTIONS

APPENDIX 1

1. Isolators are shipped fully assembled and are to be

spaced and located in accordance with installation

drawings or as otherwise recommended.

1a. Locate spring port facing outward from equip-

ment or base so that spring is visible.

2. To facilitate installation, prior to installing, VMC

recommends turning adjusting bolt “B” so that the

“Operating Clearance” marked “*” is approximately

1" to 1-1/2" for 1" deection units, 1-1/2" to 2" for 1-1/2"

deection units, and 2" to 2-1/2" for 2" deection

units.

3. Locate isolators on oor or subbase as required,

ensuring that the isolator centerline matches the

equipment or equipment base mounting holes.

Shim and/or grout as required to level all isolator

base plates “A”. A 1/4" maximum difference in ele-

vation can be tolerated.

4. Anchor all isolators to oor or subbase as required.

For installing on concrete VMC recommends HILTI

type HSL heavy duty anchors or equal.

5. Remove cap screw “C” and save. Gently place ma-

chine or machine base on top of bolt “B”. Install cap

screw “C” but DO NOT tighten.

6. The weight of the machine will cause the spring

and thus bolt “B” to descend.

7. Adjust all isolators by turning bolt “B” so that the op-

erating clearance “*” is approximately 1/4". NOTE:

It may be necessary to adjust rebound plate “D” for

clearance.

6. Check equipment level and ne adjust isolators to

level equipment.

9. Adjust rebound plate “D” so that the operating

clearance “**” is no more than 1/4".

10. Tighten cap screw “C”. Adjustment is complete.

FIG. 38 – “AEQM” SPRING-FLEX MOUNTING

LD03838

5

Loading...

Loading...