29 General Section

Sub Trim Usage and Mechanical Advantage

Sub Trim

Sub Trims are intended for relatively minor adjustments

to servo linkages and not for major trim adjustments to

the aircraft. Using excessive sub trim percentages can

cause a loss in servo resolution, where the servo

reaches its travel limit and stops moving before the

control stick is fully deflected.

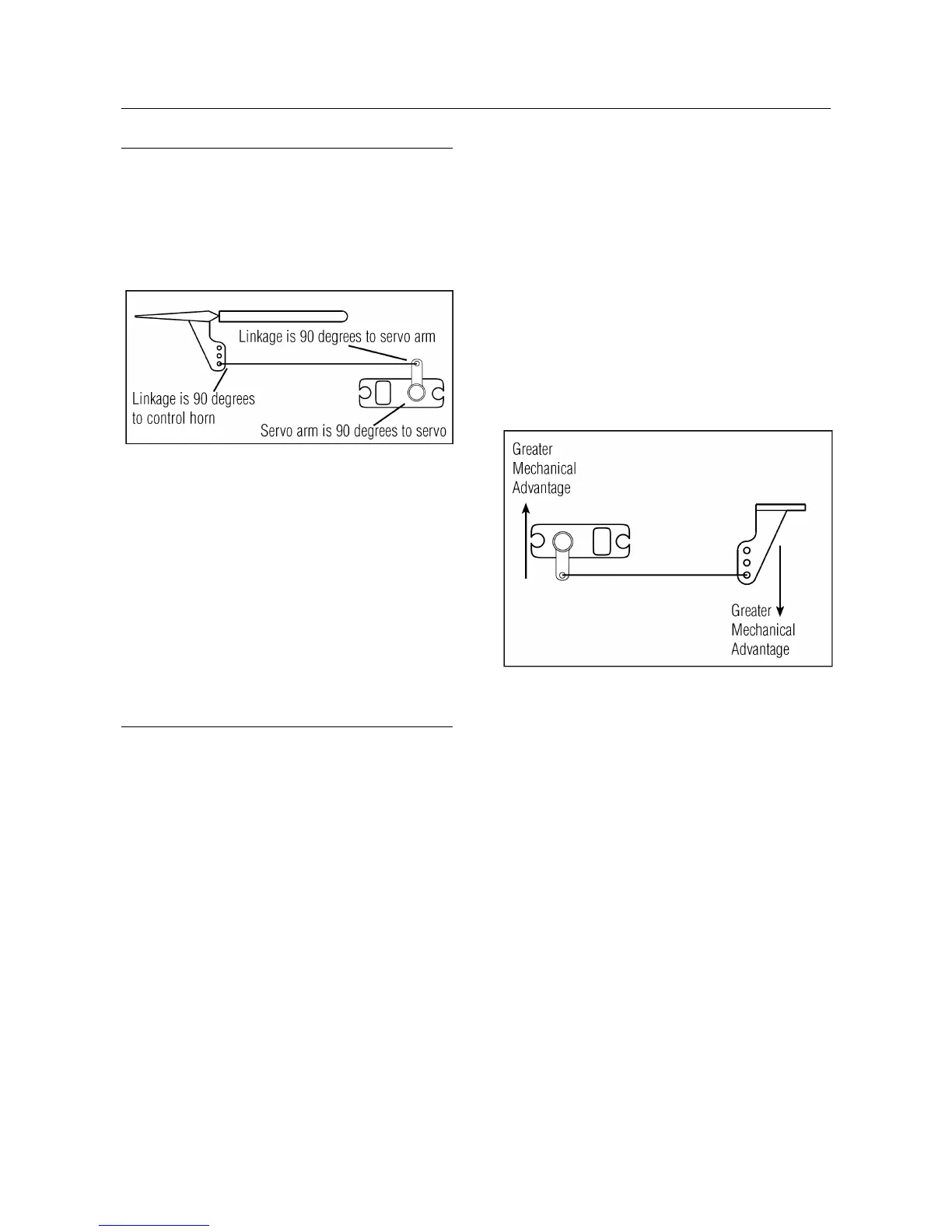

The diagram below illustrates an ideal servo/linkage

setup when the servo is at neutral (no sub trim and

digital trims centered). Notice that the servo arm is

positioned at 90˚ or perpendicular to the servo. Also

note that the linkage or rod is attached at 90˚ to both

the servo arm and the control surface horn. This setup

will result in the same amount of throw in both

directions (0 differential throw). If the servo cannot be

mounted parallel to the linkage/rod then just make sure

the servo arm is at 90˚ to the control rod when the

servo is at neutral.

Mechanical Advantage

Mechanical Advantage is a very important concept

when dealing with larger aircraft. It refers to the

leverage that the servo can exert on the control surface.

Since the control surfaces are rather large, it is

important for the servo to have enough mechanical

advantage or leverage to control them, regardless of

the servo’s rated torque. A large amount of torque is of

little value if there is not enough leverage to use it.

Insufficient leverage can lead to control surface flutter

(usually a catastrophic event) and blow-back, where the

air flow pushes the control surface backwards resulting

in mushy or no control at higher speeds.

There are two ways to increase the mechanical

advantage of the servo. One is to make sure that the

control horn device, whether it be a horn as shown in

the illustration above or a bolt with a Rocket City-type

fastener, is long enough. The horn is the lever that the

servo uses to control the surface. The longer the horn,

the more leverage the servo has. It’s like a Lug Wrench

– when you can’t get a lug nut loose you put a piece of

pipe over the end of the lug wrench to extend the

handle and that gives you more leverage to break the

lug nut free. It’s the same thing—the lug nut is the

control surface and you are the servo trying to move it.

As a general rule-of-thumb, try to attach the linkage at

the control surface so that it is at least 1” away from the

surface – longer is better.

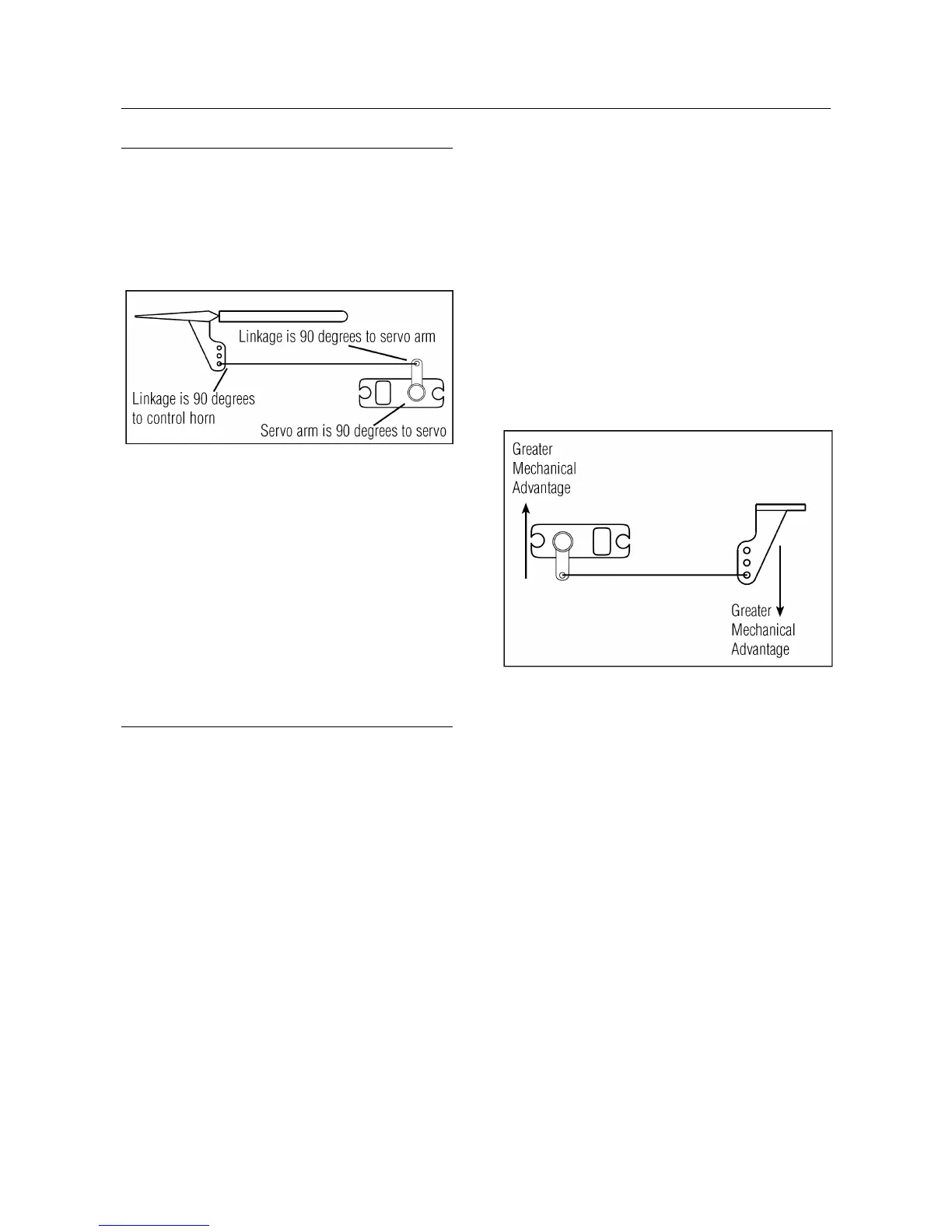

The second way to increase the mechanical advantage

for the servo is to attach the linkage at the servo arm as

far inward (towards the servo arm retaining screw) as

possible while still providing enough throw. It’s the

“lever thing” again, but in reverse, as we are taking

leverage away from the control surface by providing it

with a shorter lever to work against the servo.

Ensure that the attach point is the same distance from

the hinge line for like surfaces (two Ailerons, two

Elevators and two Rudder horns). If the attach points

are not the same distance from the hinge line there will

be unequal throw and it will be more difficult to

synchronize the surfaces for equal deflection. This is

especially critical for the Rudder where two servos are

attached to the same surface – unequal throw will

cause the servos to fight one another causing

excessive battery drain, and in severe cases may

cause servo damage.

Always try to use the maximum amount of Travel

(100%) that the radio provides. If it is too much travel,

don’t reduce the percentage of travel in the radio.

Instead, move the linkage further away from the hinge

line at the control surface and/or move the linkage

inward on the servo arm or use a shorter arm. If you

use high percentages of travel, you maintain resolution

(fine movements of the stick result in fine positive

movements of the control surface). When we decrease

travel percentages, we lose resolution.

Loading...

Loading...