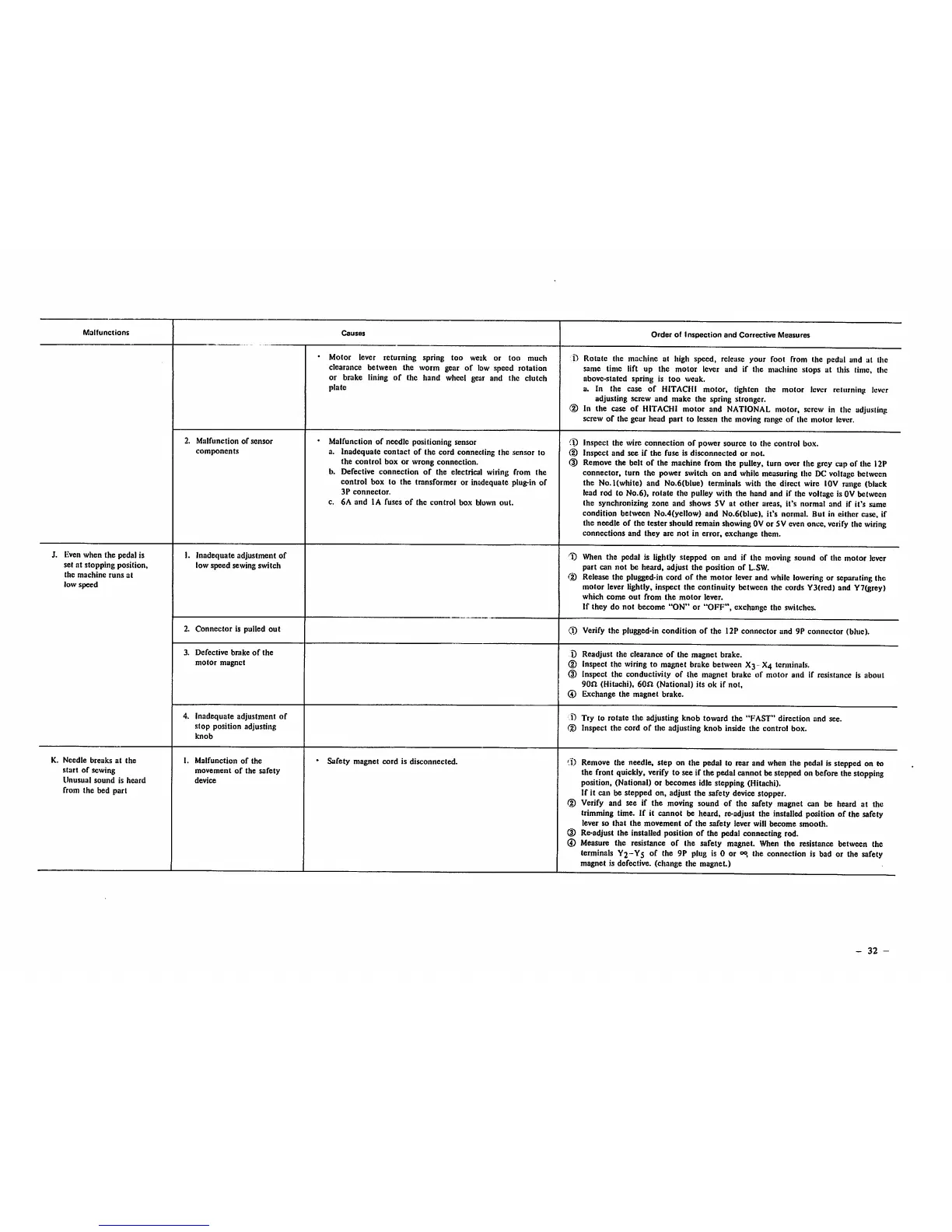

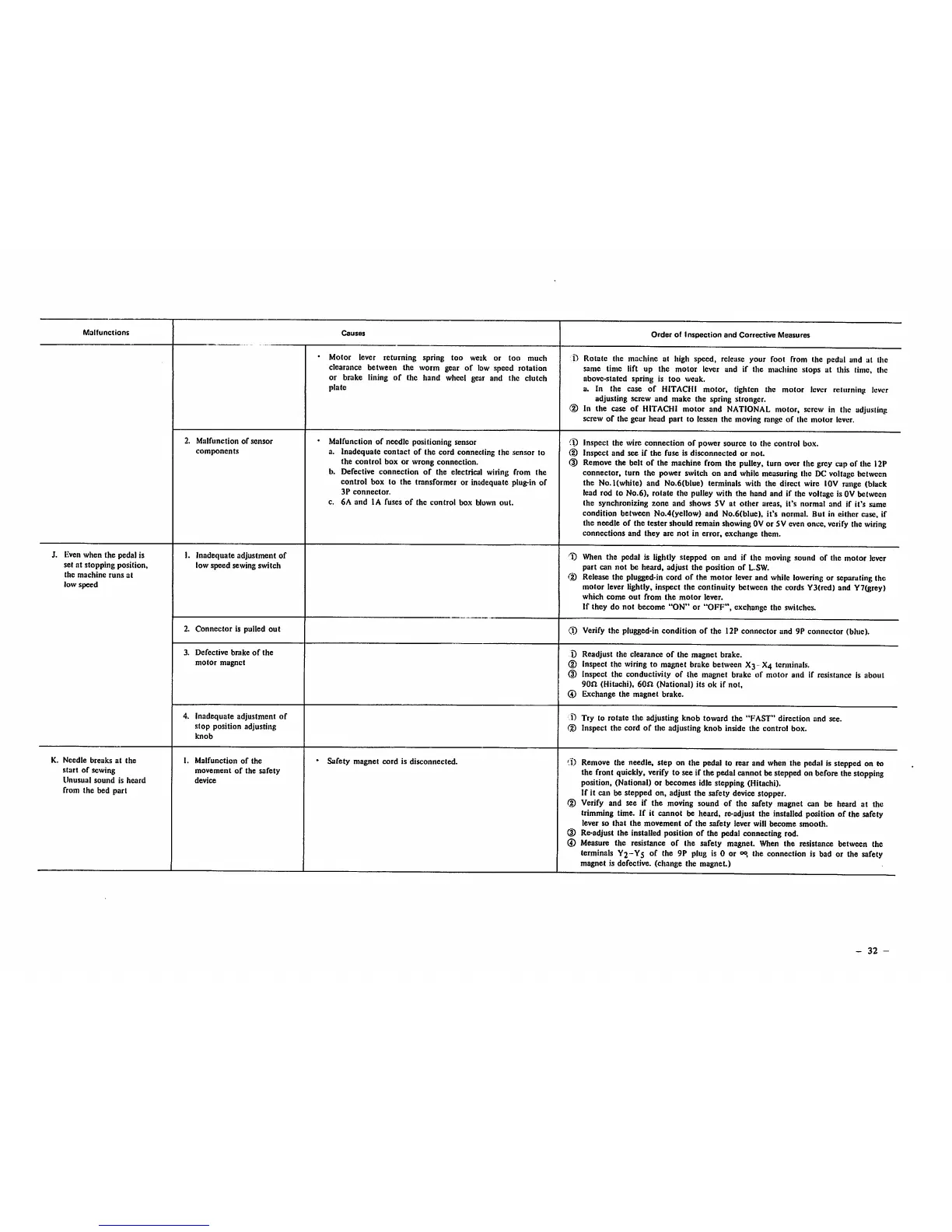

Malfunctions

Causes

Order

of

Inspection

and

Corrective

Measures

• Motor lever returning spring too weak or too much

clearance between the worm gear of low speed rotation

or brake lining of (he hand wheel gear and the clutch

plate

i) Rotate the

machine

at

high

speed,

release

your foot

from

the

pedal

and at the

same time lift up the motor lever and if the machine stops at this time, the

above-stated spring is

too

weak.

a. In the case of HITACHI motor, tighten the motor lever returning lever

adjusting screw and make the spring stronger.

(D In the

case

of

HITACHI

motor

and

NATIONAL

motor,

screw

in the

adjusting

screw of the gear head part to lessen the moving range of the motor lever.

2.

Malfunction

of

sensor

components

' Malfunction of needle positioning sensor

a. Inadequate contact of the cord connecting the sensor to

the

control

box or wrong connection.

b. Defective connection of the electrical wiring from the

control box to the transformer or inadequate plug-in of

3P

connector.

c.

6A

and

lA

fu-ses

of

the

control

box

blown

out.

(1)

Inspect the wireconnectionof power source to the control box.

(2) Inspect and see if the fuse is disconnected or not.

(D

Remove

the beltof the

machine

from

the

pulley,

turnoverthe

grey

capof the

12P

connector, turn the power switch on and while measuring the DC voltage between

the No.l(white) and No.6(blue) terminals with the direct wire lOV range (black

lead rod to No.6), rotate the pulley with the hand and if the voltage is

OV

between

the

synchronizing

zone

and

shows

5V at

other

areas,

it's

normal

and

if

it's

.same

condition

between

No.4(yellow)

and

No.6(blue),

it's

normal. But in

either

case, if

the needle of the tester should remain showing

OV

or SV even once, verify the wiring

connections and they are not in error, exchange them.

J. Kvcn when (he pedal is

set at stopping position,

the

machine

runs

at

low speed

1.

Inadequate

adjustment

of

low speed sewing switch

'D

When

the

pedal

is

lightly

stepped

on and if the

moving

sound

of the motor

lever

part

can

not

be heard,

adjust

the position of L.SW.

Release the plugged-in cord of the motor lever and while lowering or separating the

motor lever lightly, inspect the continuity between the cords V3(red) and Y7(grey)

which

come

out

from

the

motor

lever.

If they do not become "ON" or

"OFF",

exchange the switches.

2.

Connector

is pulled

out

(X)

Verify the plugged-in condition of the 12P connector and 9P connector (blue).

3.

Defective

brake

of

the

motor

magnet

X)

Readjust

the

clearance

of the magnet brake.

(D

Inspect

the

wiring

to

magnet

brake

between

X3- X4

tcrininal.s.

(D Inspect the conductivity of the magnet brake of motor and if resistance is about

90n

(Hitachi),

60f2

(National)

its

ok

if

not,

® Exchange the magnet brake.

4. Inadequate adjustment

of

stop

position adjusting

knob

D Try to rotate the adjustingknob toward the "FAST" direction and see.

® Inspect the cord of the adjusting knob inside the control box.

K.

Needle

breaks

at

(he

start

of

sewing

Unusual

sound

is

heard

from the bed part

I.

Malfunction

of

the

movement

of

the

safety

device

*

Safety

magnet

cord

is disconnected.

Remove the needle, step on the pedal to rear and when the pedal is stepped on to

the front quickly,verify to seeif the pedalcannot besteppedon before the stopping

position, (National) or becomes idle stepping (Hitachi).

If it can be stepped on, adjust the safety device stopper.

® Verify and see if the

moving

sound of the safety magnet can be heard at the

trimming time. If it cannot be heard, re-adjust the installed position of the safety

lever so

that

the

movement

of

the

safety

lever will

become

smooth.

®

Re-adjust

the installed positionof the pedal

connecting

rod.

®

Measure

the

resistance

of the safety

magnet.

When

the

resistance

between

the

terminals Y2~Y5 of the 9P plug is 0 or the connection is bad or the safety

magnet is defective, (change the

magnet)

-

32

Loading...

Loading...