8.

Adjusting

the

slide

shaft

The

moving

range

of the

slide

shaft

(Fig.34

®) is

5.4mm(7/32").

This

is

adjusted

by

moving

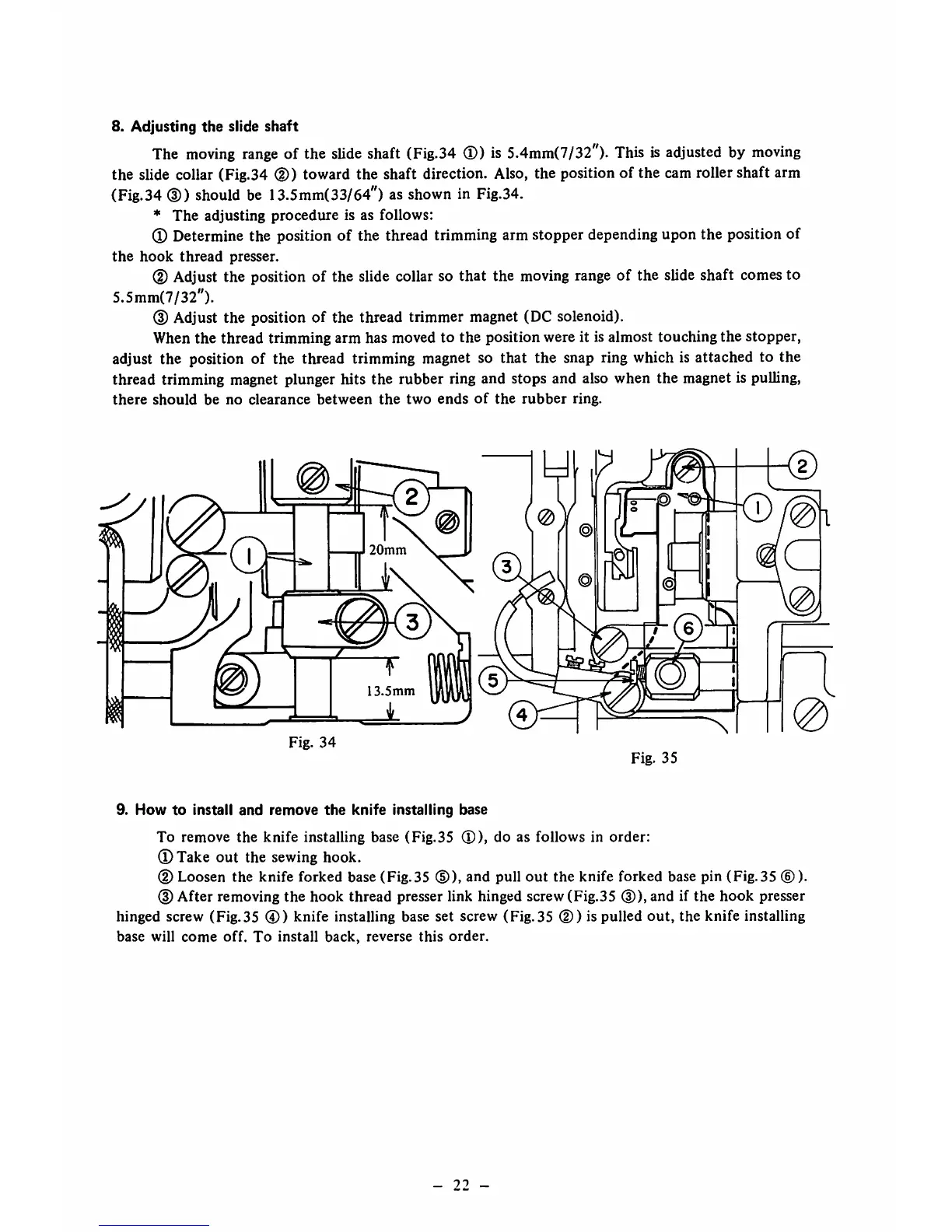

the slide collar (Fig.34 (D) toward the shaft direction. Also, the position of the cam roller shaft arm

(Fig.34 (D) should be 13.5mm(33/64") as

shown

in

Fig.34.

*

The

adjusting

procedure

is as follows:

(D Determine the position of the thread trimming arm stopper depending upon the position of

the

hook

thread

presser.

(D Adjust the position of the slide collar so

that

the moving range of the slide shaft comes to

5.5mm(7/32").

(D Adjust the position of the thread trimmer magnet (DC solenoid).

When

the

thread trimming arm has moved to

the

position were it is almost touching

the

stopper,

adjust the position of the thread trimming magnet so that the snap ring which is attached to the

thread trimming magnet plunger hits the rubber ring and stops and also when the magnet is pulling,

there

should

be

no

clearance

between

the

two

ends

of

the

rubber

ring.

E

20mm

13.5mm

Fig.

34

Fig.

35

9.

How

to

install

and

remove

the

knife

installing base

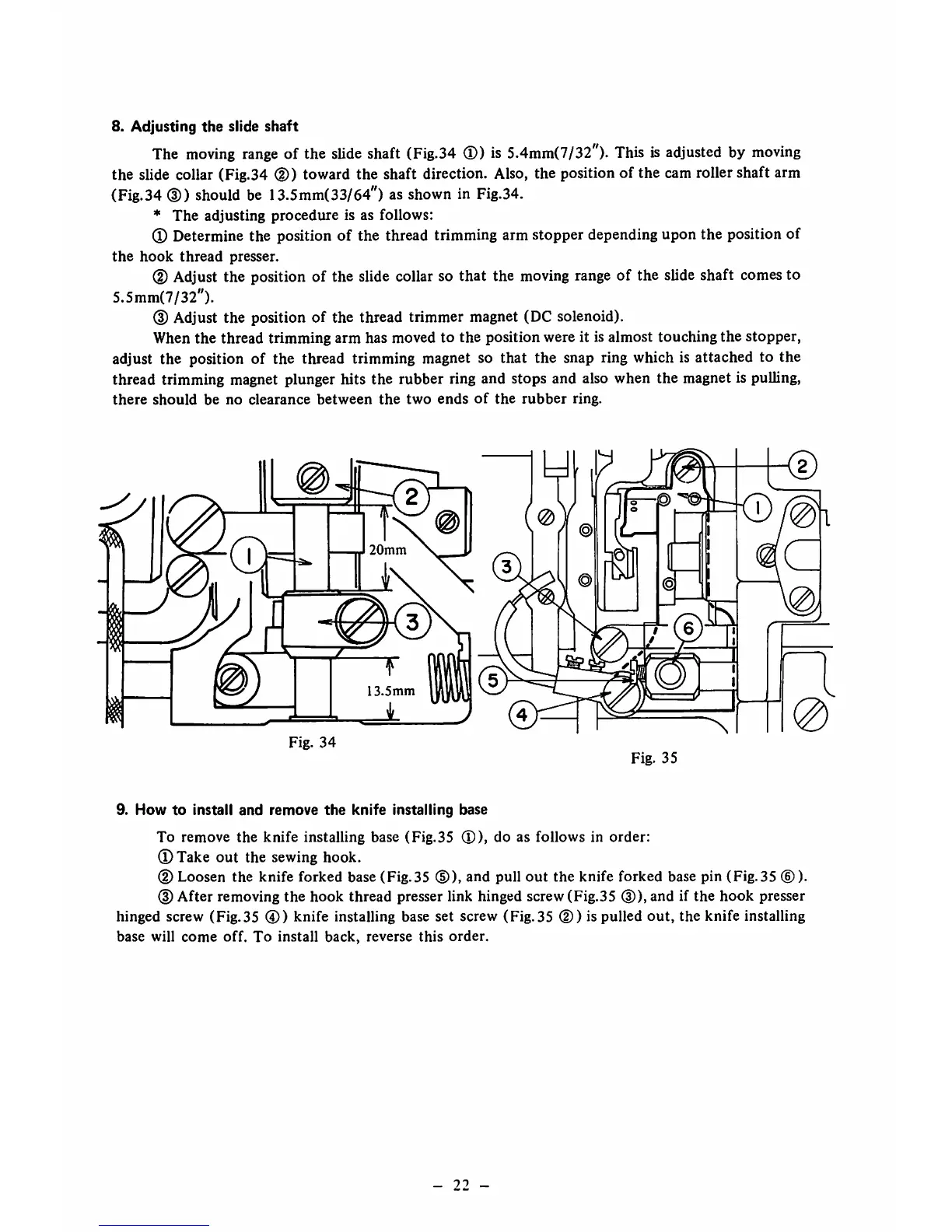

To remove

the

knife

installing base (Fig.35

®),

do as follows in

order:

®Take

out the sewing hook.

(D Loosen the knife forked base (Fig.35 (D), and pull

out

the

knife forked base pin

(Fig.35

(D).

(D After removing

the

hook

thread presser link hinged screw (Fig.35 (D), and if

the

hook

presser

hinged screw

(Fig.35

®)

knife

installing base set screw

(Fig.35

(D) is pulled

out,

the

knife

installing

base

will

come

off.

To

install

back,

reverse

this

order.

Loading...

Loading...