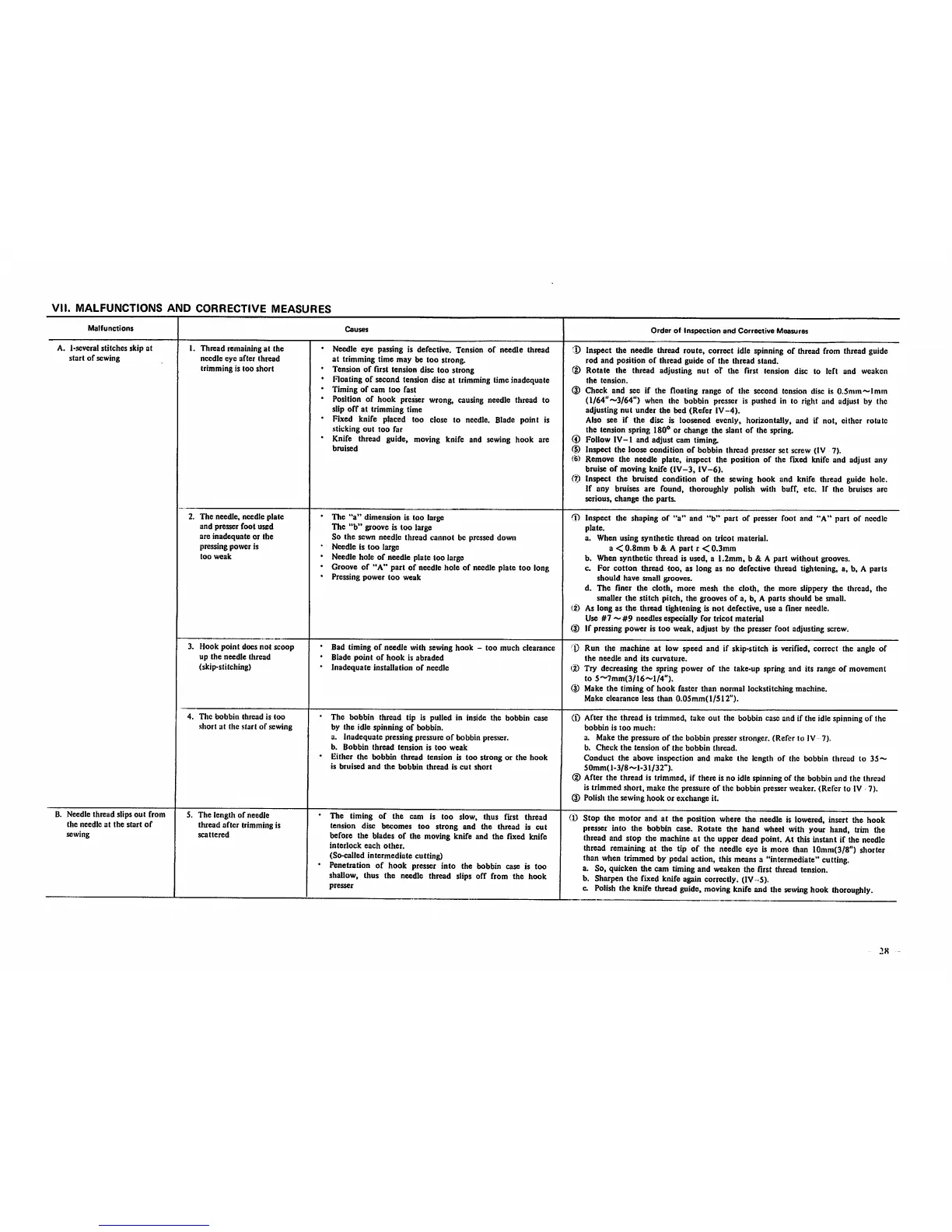

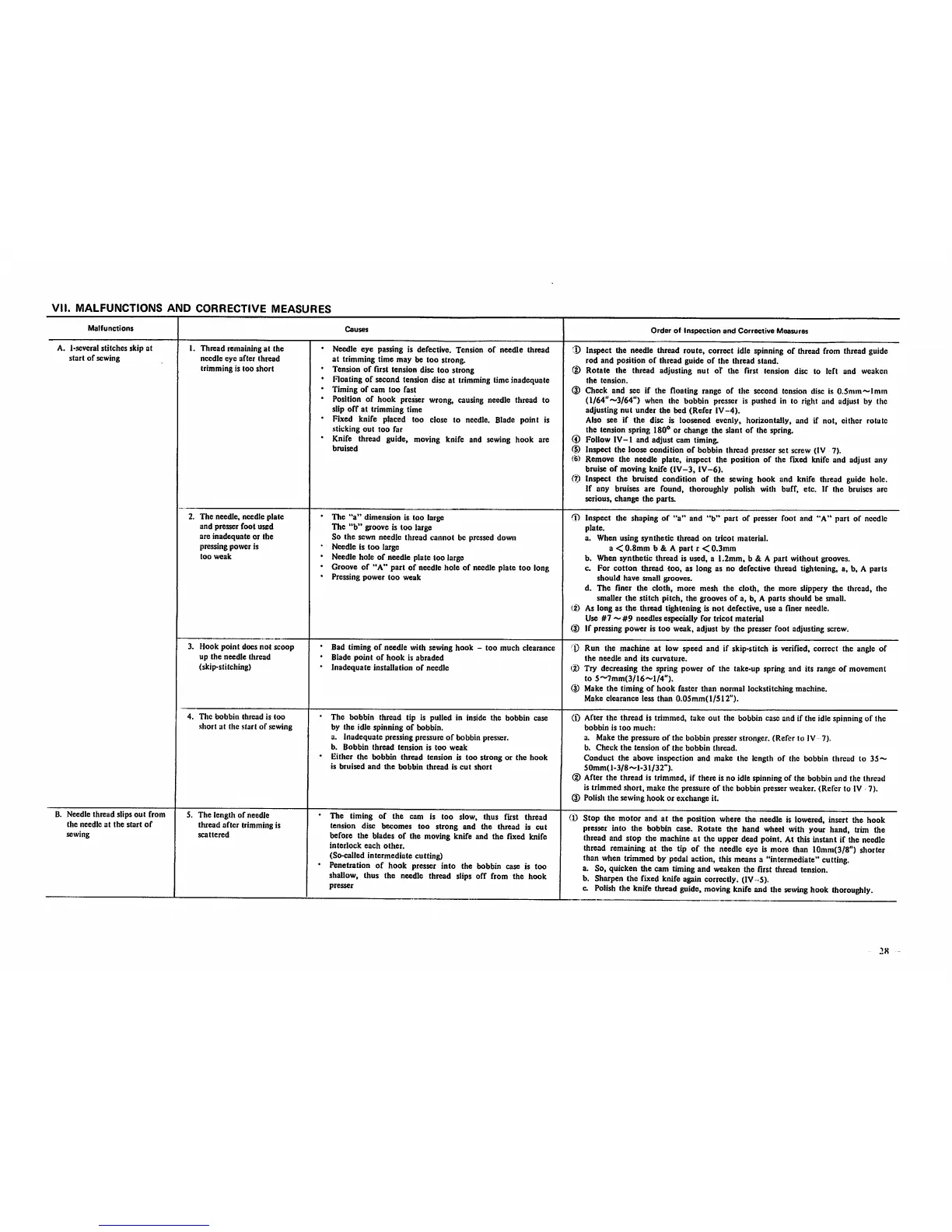

VII.

MALFUNCTIONS

AND

CORRECTIVE

MEASURES

Malfunctions

Causes

Order

of

Inspection

and

Corrective

Measures

A. l-scvcral stitches skip at

start

of

sewing

1.

Thread

remaining at the

needle

eye

after

thread

trimming

is too

short

* Needle eye passing is defective. Tension

of

needle thread

at trimming time may be too strong.

' Tension of first tension disc too strong

* Floating of second tension disc at trimming time inadequate

* Timing

of

cam

too

fast

* Position of hook presser wrong, causing needle thread to

slip

off

at trimming time

* Fixed knife placed too close to needle. Blade point is

sticking

out

too

far

* Knife thread guide, moving knife and sewing hook are

bruised

'D

Inspect

the

needle

thread

route,

correct

idle

spinning

of

thread

from

thread

guide

rod

and

position

of

thread

guide

of

the thread stand.

® Rotate the thread adjusting nut of the first

tension

disc to left and

weaken

the

tension.

(D Check and see if the floating range of the second tension disc is 0.5mm~lmm

(l/64"~3/64") when the bobbin

presser

is

pushed

in to right and adjust by the

adjusting

nut

under

the bed

(Refer

iV-4).

Also see if

the

disc is loosened evenly, horizontally, and if not, cither rotate

the tension spring 180° or change the slant of the spring.

(4)

FollowIV-1 and adjust cam

timing.

(D

Inspect

the loosecondition of

bobbin

thread

presser

set

screw

(IV 7).

(6) Remove the needle plate, inspect the position of the fixed knife and adjust any

bruise

of

moving knife

(lV-3,

lV-6).

(T)

Inspect the bruised condition of the sewing hook and knife thread guide hole.

If any bruises are found, thoroughly polish with buff, etc. If the bruises are

serious, change

the

parts.

2. The needle, needle plate

and

presser

foot

used

are

inadequate

or the

pressing power is

too

weak

* The

"a"

dimension is too large

The

"b"

groove is too large

So the sewn needle thread cannot be pressed down

* Needle is too large

* Needle hole of needle plate too large

* Groove of "A" part of needle hole of needle plate too long

* Pressing

power

too

weak

(T)

Inspect the shaping of "a" and

"b"

part of presser foot and "A" part of needle

plate.

a. When using

synthetic

thread

on

tricot

material.

a <

0.8mm

b & A

part

r <

0.3mm

b. When synthetic thread is used, a 1.2mm, b & A

part

without grooves.

c. For

cotton

thread

too,

as long as no defective thread tightening, a, b, A parts

should

have

small

grooves.

d. The finer the cloth, more mesh the cloth, the more slippery the thread, the

smaller the stitch pitch, the grooves of a, b, A parts should be small.

® As long as the thread tightening is not defective, use a finer needle.

Use

#7

#9

needles especially for

tricot

material

(3) If pressing power is too weak, adjust by the presser foot adjusting screw.

3. Hook point does not scoop

up

the

needle

thread

(skip-stitching)

' Bad timing of needle with sewing hook - too much clearance

' Blade

point

of

hook

is

abraded

*

Inadequate

installation

of

needle

(f) Run the

machine

at low speed and if skip-stitch is

verified,

correct the

angle

of

the

needle

and

its

curvature.

® Try

decreasing

the spring power of the take-up springand its range of movement

to

5~7mm(3/16~l/4").

<D

Make the timing of hook faster than normal lockstitchingmachine.

Make clearance less

than

0.0Smm(l/S12").

4.

The

bobbin

thread

is

too

short

at the start of sewing

' The bobbin thread tip is pulled in inside the bobbin case

by

the

idle spinning

of

bobbin.

a. Inadequate pressingpressureof bobbin presser.

b.

Bobbin

thread

tension

is

too

weak

* Fither the bobbin thread tension is too strong or the hook

is

bruised

and

the

bobbin

thread

is

cut

short

(D After the thread is trimmed, take out the bobbin caseand if the idlespinningof the

bobbin

is

too

much:

a. Make the pressure of the bobbin presser stronger. (Refer to IV 7).

b.

Check

the

tension

of

the

bobbin

thread.

Conduct the above inspection and make the length of the bobbin thread to

35^

50mm(l-3/8~l-31/32").

(D After the thread is

trimmed,

if there is no idle

spinning

of the bobbinand the thread

is trimmed short, make the pressure of the bobbin presser weaker.(Refer to IV 7).

®

Polisli

the sewinghook or exchangeit.

B. Needle thread slips

out

from

the

needle

at

the

start

of

sewing

5. The length

of

needle

thread

after

trimming is

scattered

* The timing of the cam is too slow, thus first thread

tension disc becomes too strong and the thread is cut

before the blades of the moving knife and the fixed knife

interlock

each

other.

(So-called intermediate cutting)

• Penetration of

hook

presser into the bobbin case is too

shallow, thus the needle thread slips off from the hook

presser

(D Stop the motor and at the

position

where

the

needle

is

lowered,

insert

the hook

presser into the bobbin case. Rotate the hand wheel with your hand, trim the

thread and stop the machine at the upper dead point. At this instant if the needle

thread

remaining

at the tip of the needle eye is more than 10mm(3/8") shorter

than

when

trimmed

by

pedal

action,

this

means

a "intermediate"

cutting.

a. So, quicken the cam timing and weaken the first thread tension.

b. Sharpen the fixed knife again correctly.

(IV-5).

c.

Polish

the knifethread

guide,

moving

knifeand the

sewing

hook

thoroughly.

28

Loading...

Loading...