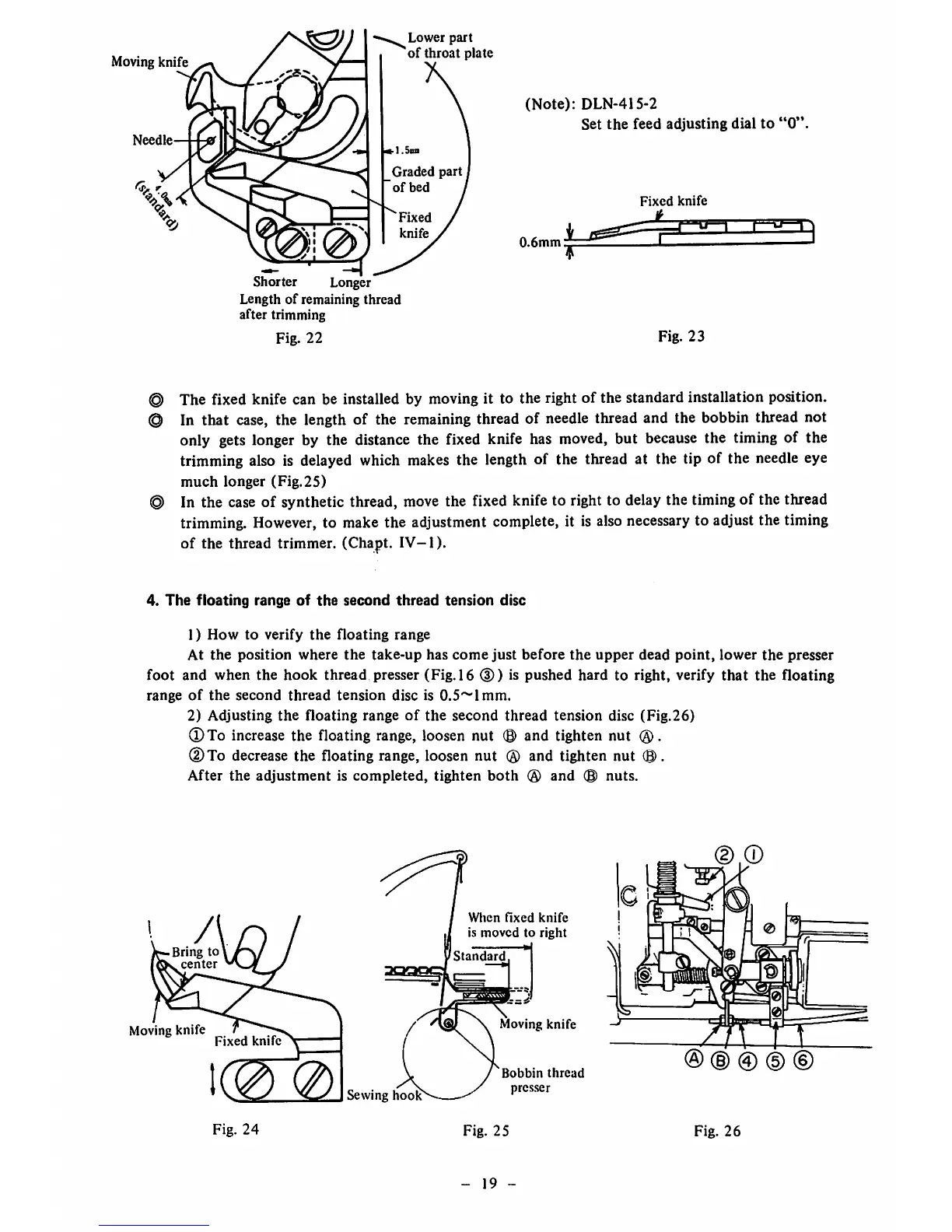

Moving knife

Needle

a

Shorter Longer

Length of remaining thread

after trimming

Fig.

22

Lower

part

of

throat

plate

i.5bb

Graded

part

of

bed

(Note):

DLN-415-2

Set

the

feed adjusting dial to

"0".

Fixed

knife

0.6mm

Fig.

23

The fixed knife can be installed by moving it to the right of the standard installation position.

In that case, the length of the remaining thread of needle thread and the bobbin thread not

only gets longer by the distance the fixed knife has

moved,

but

because

the timing of the

trimming also is delayed which makes the length of the thread at the tip of the needle eye

much

longer

(Fig.25)

In the case of synthetic thread, move the fixed knife to right to delay the timing of the thread

trimming. However, to make the adjustment complete, it is also necessary to adjust the timing

of

the

thread

trimmer.

(Chapt.

IV-1).

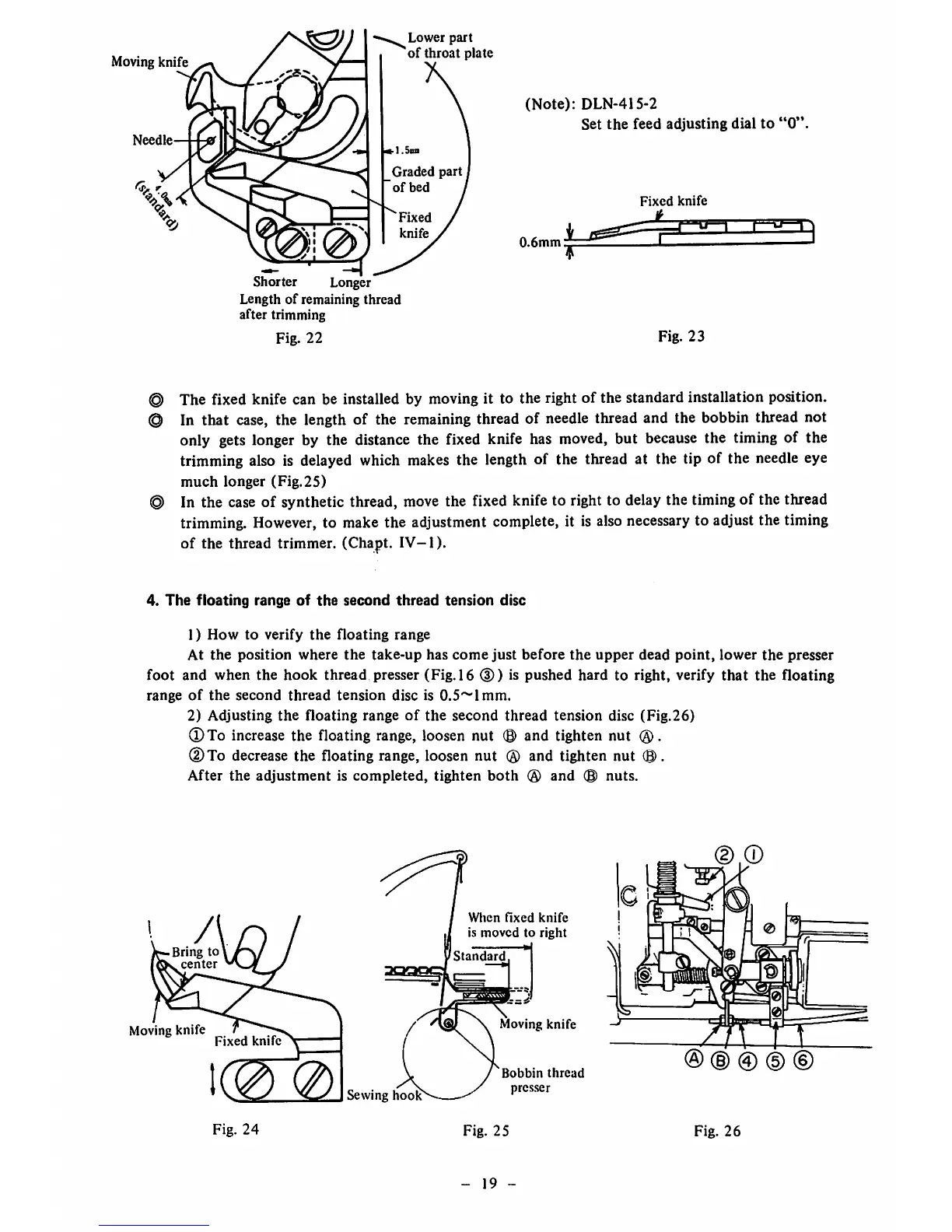

4.

The

floating

range

of

the

second

thread

tension

disc

1)

How

to

verify

the

floating

range

At

the

position

where

the

take-up

has

come

just

before

the

upper

dead

point,

lower

the

presser

foot and when the hook thread presser (Fig. 16 (D) is pushed hard to right, verify

that

the floating

range

of

the

second

thread

tension

disc is

0.5~lmm.

2)

Adjusting

the

floating

range

of

the

second

thread

tension

disc

(Fig.26)

(DTo increase the floating range, loosen nut

(B)

and tighten nut

©.

©To

decrease the floating range, loosen nut

(g)

and tighten nut

©.

After

the

adjustment

is

completed,

tighten

both

®

and

(B>

nuts.

Bring

to

center

Moving knife

Fixed

knife

l(M

Fig.

24

Sewing

Wlien

fixed

knife

is

moved

to

right

Standard

Moving knife

Bobbin

thread

presser

Fig.

25

-

19

-

®

(D

® d) ©

Fig.

26

Loading...

Loading...