– 99 –

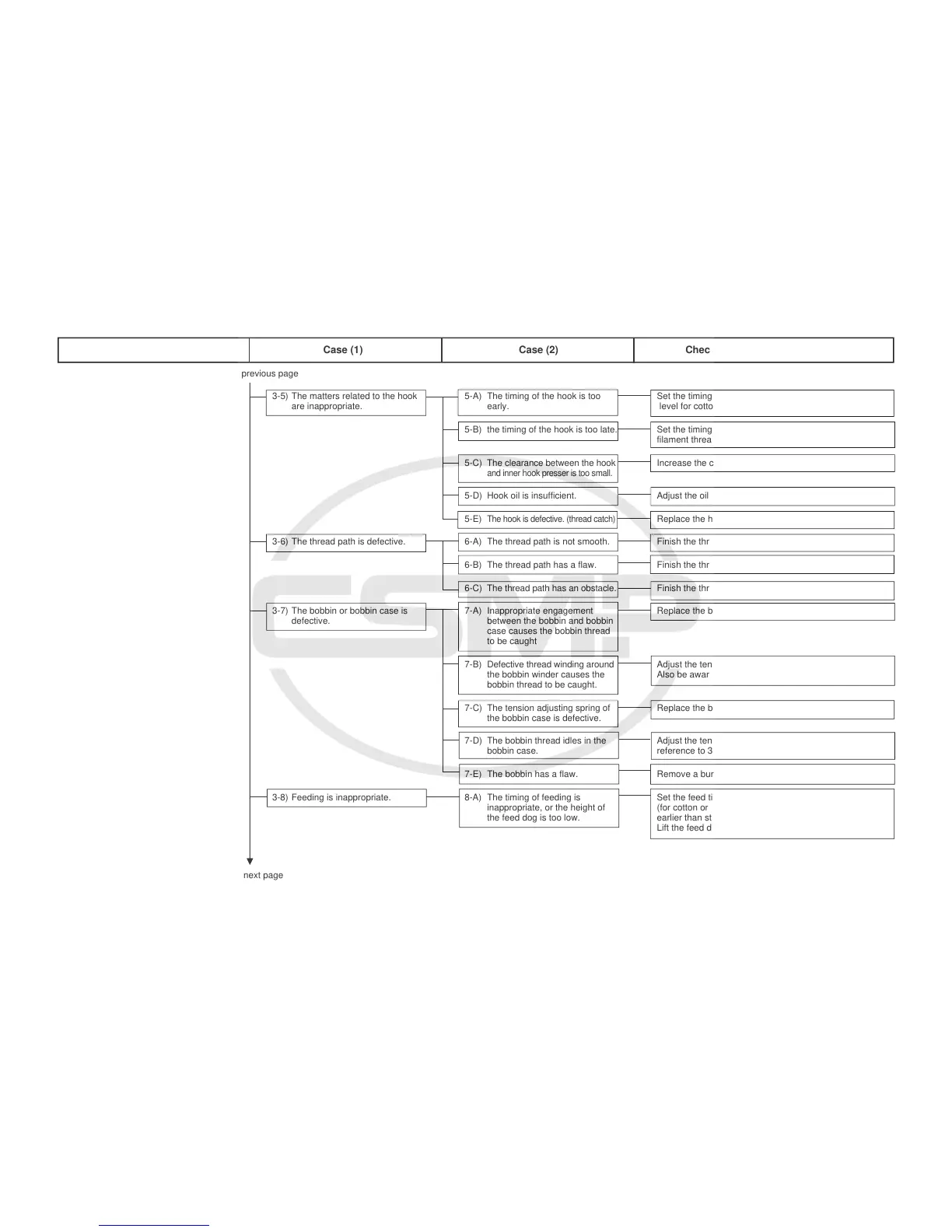

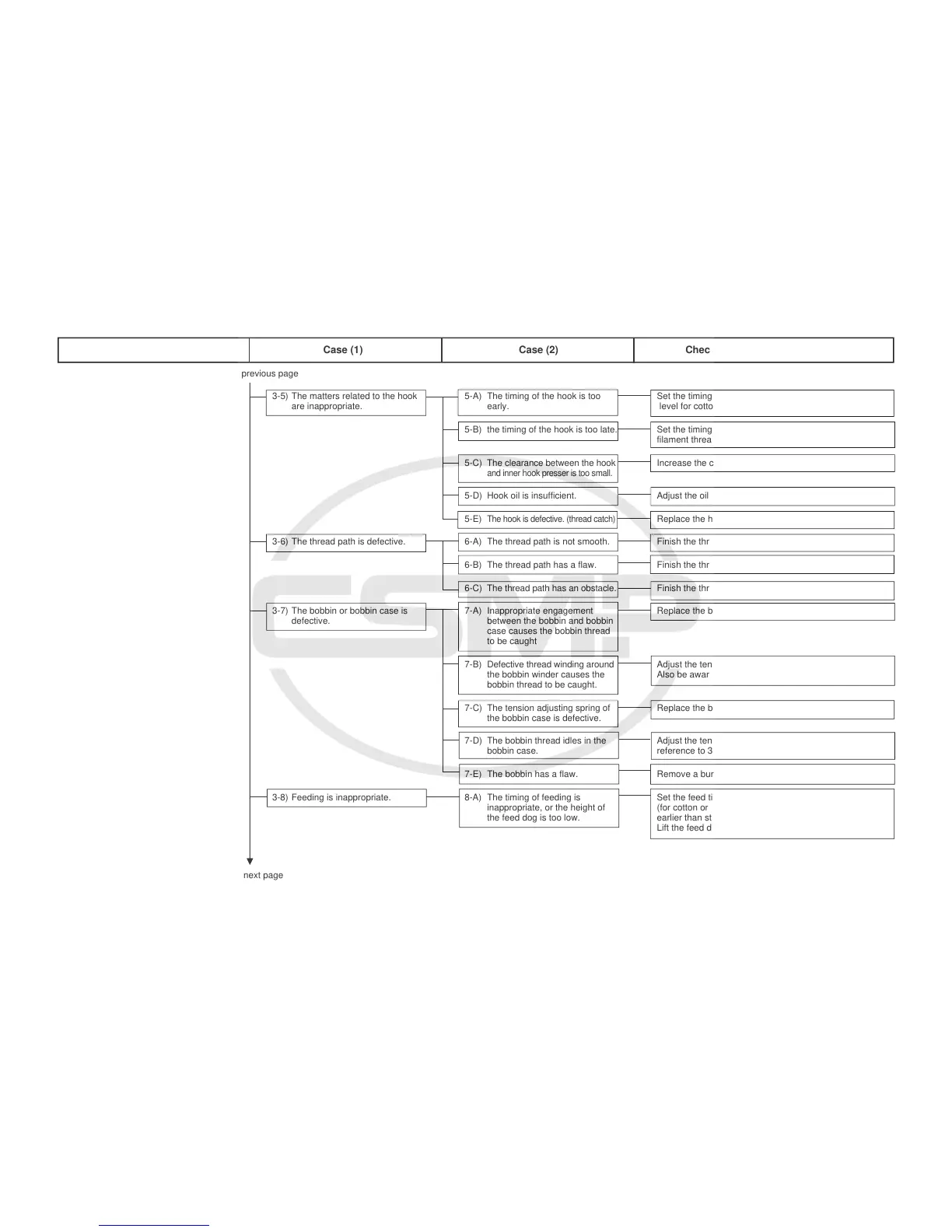

3-5) The matters related to the hook 5-A) The timing of the hook is too Set the timing of the hook to the standard or slightly late

are inappropriate. early. level for cotton or spun thread.

5-B) the timing of the hook is too late. Set the timing of the hook to the slightly early level for

filament thread.

5-C) The clearance between the hook Increase the clearance to smooth the thread passing.

and inner hook presser is too small.

5-D) Hook oil is insufficient. Adjust the oil volume to the appropriate level.

5-E)

The hook is defective. (thread catch)

Replace the hook.

3-6) The thread path is defective. 6-A) The thread path is not smooth. Finish the thread path appropriately.

6-B) The thread path has a flaw. Finish the thread path appropriately.

6-C) The thread path has an obstacle. Finish the thread path appropriately to correct threading.

3-7) The bobbin or bobbin case is 7-A) Inappropriate engagement Replace the bobbin or bobbin case.

defective. between the bobbin and bobbin

case causes the bobbin thread

to be caught

7-B) Defective thread winding around Adjust the tension and position of the bobbin thread.

the bobbin winder causes the Also be aware of uneven winding.

bobbin thread to be caught.

7-C) The tension adjusting spring of Replace the bobbin case.

the bobbin case is defective.

7-D) The bobbin thread idles in the Adjust the tension of the idling prevention spring with

bobbin case. reference to 3.-(5).

7-E) The bobbin has a flaw. Remove a burr at the flaw portion, or replace the bobbin.

3-8) Feeding is inappropriate. 8-A) The timing of feeding is Set the feed timing to a level slightly later than standard

inappropriate, or the height of (for cotton or spun thread). Set the feed timing to a level

the feed dog is too low. earlier than standard (for filament thread).

Lift the feed dog height.

Trouble Case (1) Case (2) Check and Corrective measures

To the next page

From the previous page

Loading...

Loading...