– 102 –

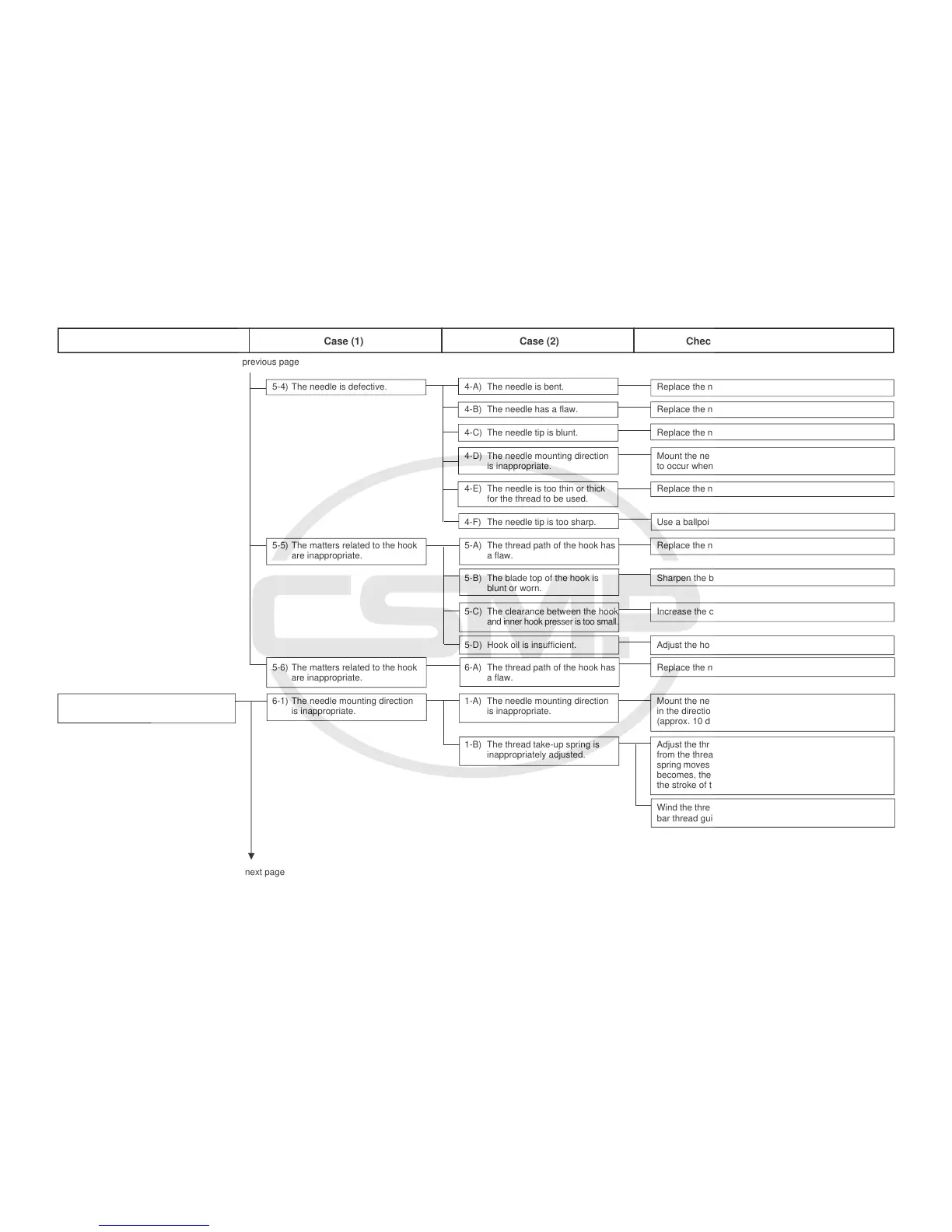

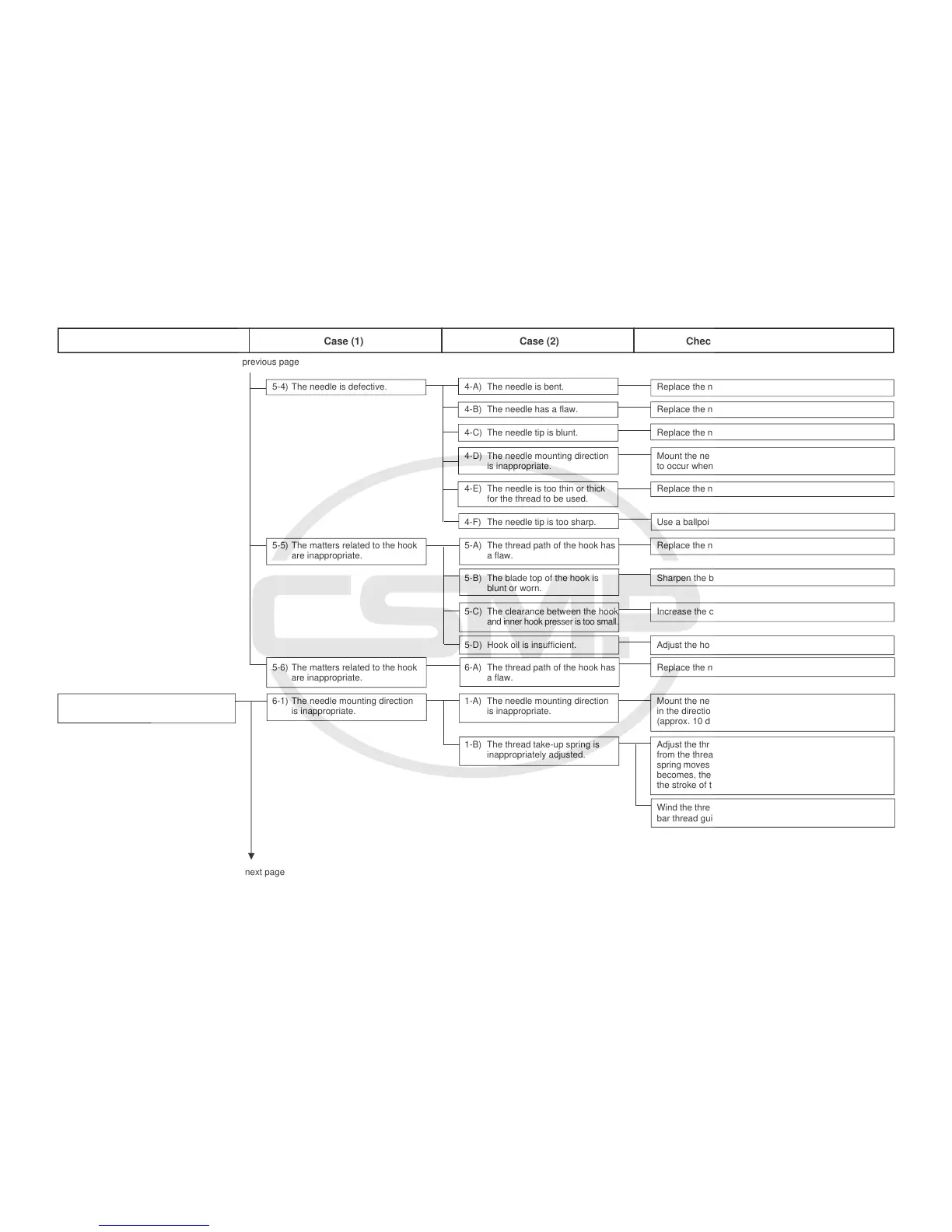

5-4) The needle is defective. 4-A) The needle is bent. Replace the needle.

4-B) The needle has a flaw. Replace the needle.

4-C) The needle tip is blunt. Replace the needle.

4-D) The needle mounting direction Mount the needle appropriately. Defective sewing is likely

is inappropriate. to occur when the needle recess portion faces frontward.

4-E) The needle is too thin or thick Replace the needle.

for the thread to be used.

4-F) The needle tip is too sharp. Use a ballpoint needle.

5-5) The matters related to the hook 5-A) The thread path of the hook has Replace the needle.

are inappropriate. a flaw.

5-B) The blade top of the hook is Sharpen the blade top of the hook or replace the needle.

blunt or worn.

5-C) The clearance between the hook Increase the clearance to smooth the thread passing.

and inner hook presser is too small.

5-D) Hook oil is insufficient. Adjust the hook oil volume to the appropriate level.

5-6) The matters related to the hook 6-A) The thread path of the hook has Replace the needle.

are inappropriate. a flaw.

6. Thread breakage at back or back-tuck 6-1) The needle mounting direction 1-A) The needle mounting direction Mount the needle so that the needle recess portion faces

sewing is inappropriate. is inappropriate. in the direction of slightly opposite side of the operator

(approx. 10 degrees) from the exactly lateral direction.

1-B) The thread take-up spring is Adjust the thread take-up spring so that the thread is not fed

inappropriately adjusted. from the thread tension disk before the thread take-up

spring moves to the end. (The more effective this adjustment

becomes, the lower the spring tension is set or the longer

the stroke of the spring is set.)

Wind the thread around the needle or use the T-type needle

bar thread guide (B1418227T00).

Trouble Case (1) Case (2) Check and Corrective measures

To the next page

From the previous page

Loading...

Loading...