1007.GB

E 34

10 Troubleshooting

This chapter is designed to help the user identify and rectify basic faults or the results

of incorrect operation. When locating a fault, proceed in the order shown in the table.

Z

If the fault cannot be rectified after carrying out the remedial procedure, notify the

manufacturer’s service department, as any further troubleshooting can only be

performed by specially trained and qualified service personnel.

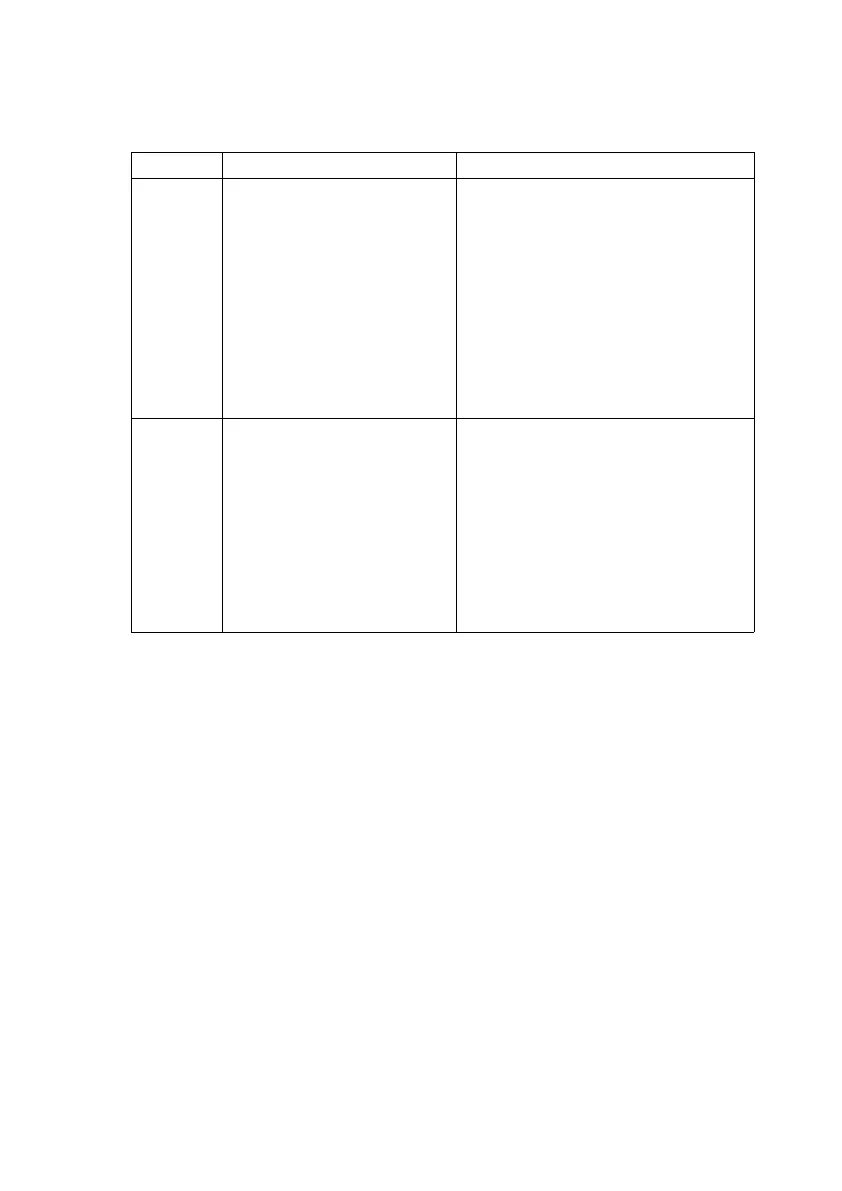

Fault Probable Cause Action

Truck

does not

move

– Battery connector not

connected.

– Isolator (Emergency Stop)

depressed.

– Key switch set to "0"

– Code lock switched off

– Battery charge too low.

– Platform switch not applied.

– Faulty fuse.

– Check the battery connector and

connect if necessary.

– Release isolator

– Set the key switch to position “I”.

– Enter operator code.

– Check the charging condition of

the battery and recharge if

necessary.

– Press the platform switch.

– Check fuses F1 and 1F1.

Lifting

inhibited.

– Truck not

operational.

– Hydraulic oil level too low.

– Battery discharge monitor

has cut out and indicates

“STOP”.

– Faulty fuse.

– Excessive load.

– Perform all remedial actions listed

under the fault “Truck does not

move”.

– Check hydraulic oil level.

– Charge the battery.

– Check fuse 2F1.

– Note maximum capacity

(see data plate)

1007.GB

E 34

10 Troubleshooting

This chapter is designed to help the user identify and rectify basic faults or the results

of incorrect operation. When locating a fault, proceed in the order shown in the table.

Z

If the fault cannot be rectified after carrying out the remedial procedure, notify the

manufacturer’s service department, as any further troubleshooting can only be

performed by specially trained and qualified service personnel.

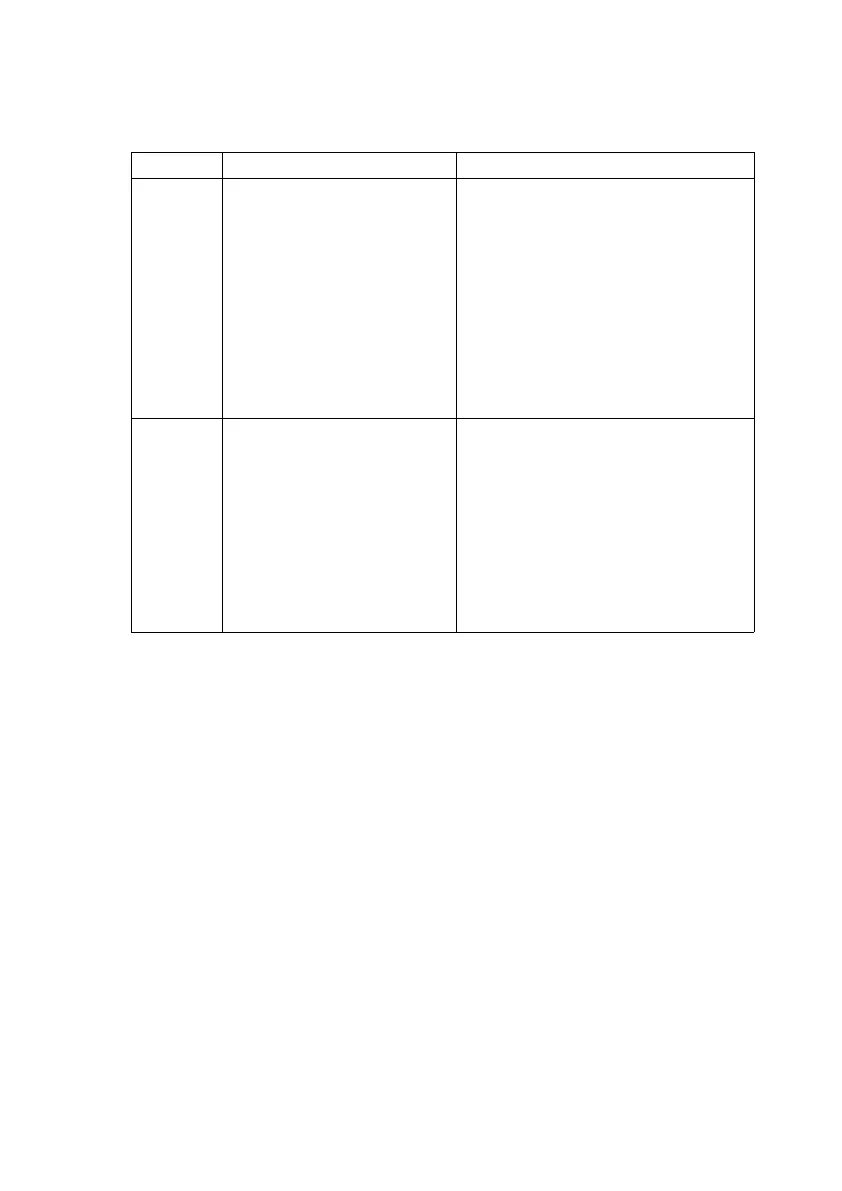

Fault Probable Cause Action

Truck

does not

move

– Battery connector not

connected.

– Isolator (Emergency Stop)

depressed.

– Key switch set to "0"

– Code lock switched off

– Battery charge too low.

– Platform switch not applied.

– Faulty fuse.

– Check the battery connector and

connect if necessary.

– Release isolator

– Set the key switch to position “I”.

– Enter operator code.

– Check the charging condition of

the battery and recharge if

necessary.

– Press the platform switch.

– Check fuses F1 and 1F1.

Lifting

inhibited.

– Truck not

operational.

– Hydraulic oil level too low.

– Battery discharge monitor

has cut out and indicates

“STOP”.

– Faulty fuse.

– Excessive load.

– Perform all remedial actions listed

under the fault “Truck does not

move”.

– Check hydraulic oil level.

– Charge the battery.

– Check fuse 2F1.

– Note maximum capacity

(see data plate)

Loading...

Loading...