F 5

0708.GB

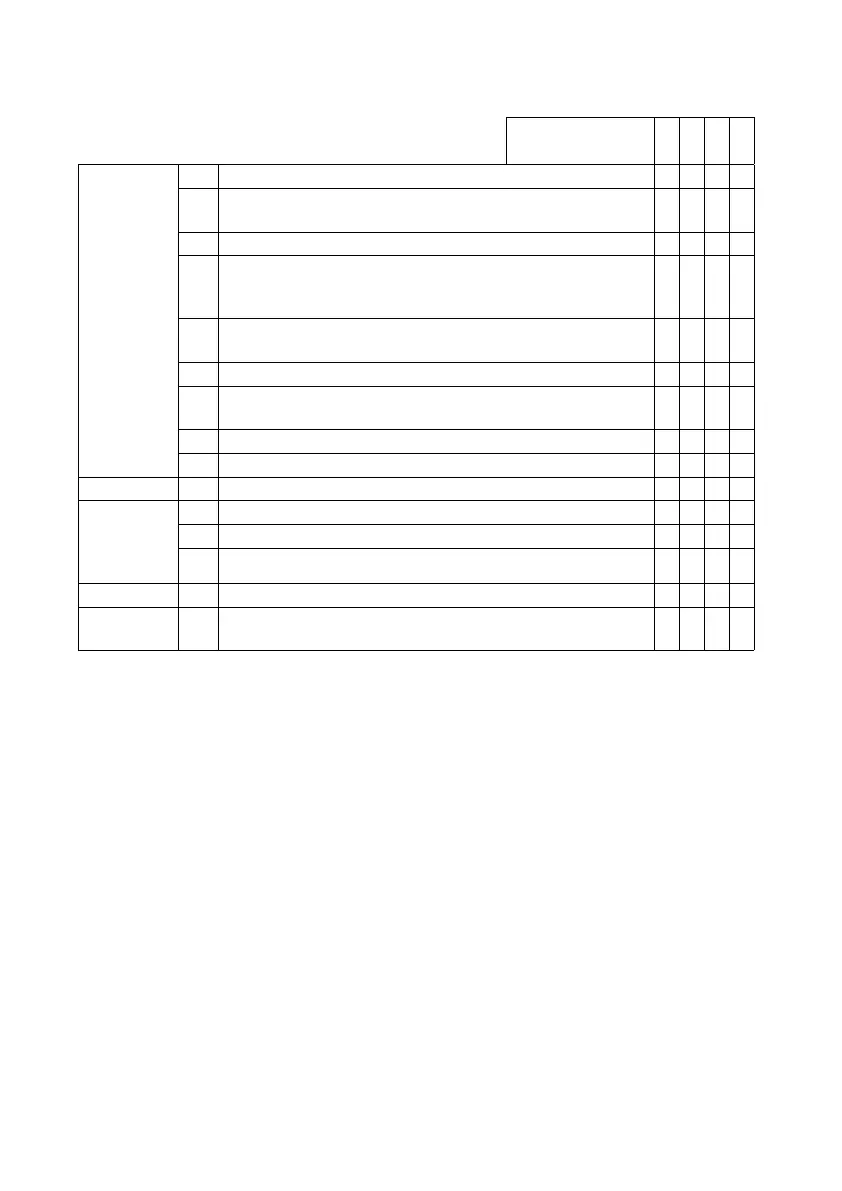

Maintenance Intervals

Standard = t WA B C

Cold store = k

Hydraulic

operation

6.1 Visually inspect rollers, slide pieces and stops. kt

6.2 Test operation of lift mechanism, check for wear and check

settings.

kt

6.3 Test hydraulic system. kt

6.4 Check that hose and pipe lines and their connections are

secure, check for leaks and damage, and tighten unions if

necessary.

kt

6.5 Check cylinders and piston rods for damage and leaks, and

make sure they are secure

kt

6.6 Check hydraulic oil level. kt

6.7 Replace hydraulic oil. (This may have to be performed via

a specialist environmental service truck)

kt

6.8 Check hydraulic oil filter, clean and replace if necessary kt

6.9 Tie rods t

Agreed

perfor-

mance

levels

7.1 Lubricate truck in accordance with Lubrication Schedule. kt

7.2 Test run t

7.3 Demonstration after servicing kt

Steering

system

8.1 Test electric steering. t

F 5

0708.GB

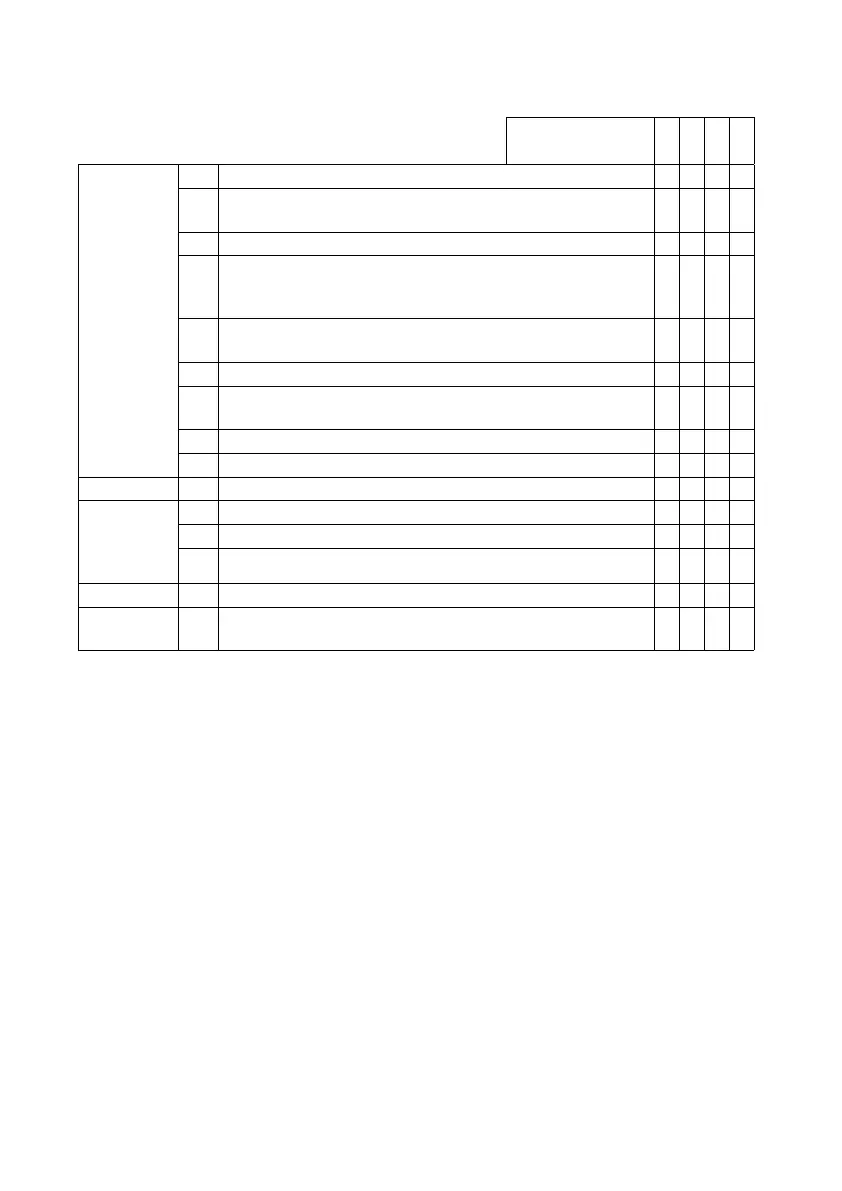

Maintenance Intervals

Standard = t WA B C

Cold store = k

Hydraulic

operation

6.1 Visually inspect rollers, slide pieces and stops. kt

6.2 Test operation of lift mechanism, check for wear and check

settings.

kt

6.3 Test hydraulic system. kt

6.4 Check that hose and pipe lines and their connections are

secure, check for leaks and damage, and tighten unions if

necessary.

kt

6.5 Check cylinders and piston rods for damage and leaks, and

make sure they are secure

kt

6.6 Check hydraulic oil level. kt

6.7 Replace hydraulic oil. (This may have to be performed via

a specialist environmental service truck)

kt

6.8 Check hydraulic oil filter, clean and replace if necessary kt

6.9 Tie rods t

Agreed

perfor-

mance

levels

7.1 Lubricate truck in accordance with Lubrication Schedule. kt

7.2 Test run t

7.3 Demonstration after servicing kt

Steering

system

8.1 Test electric steering. t

Loading...

Loading...