0708.USA

G 8

p) Replace hydraulic hoses after 6 years' operation

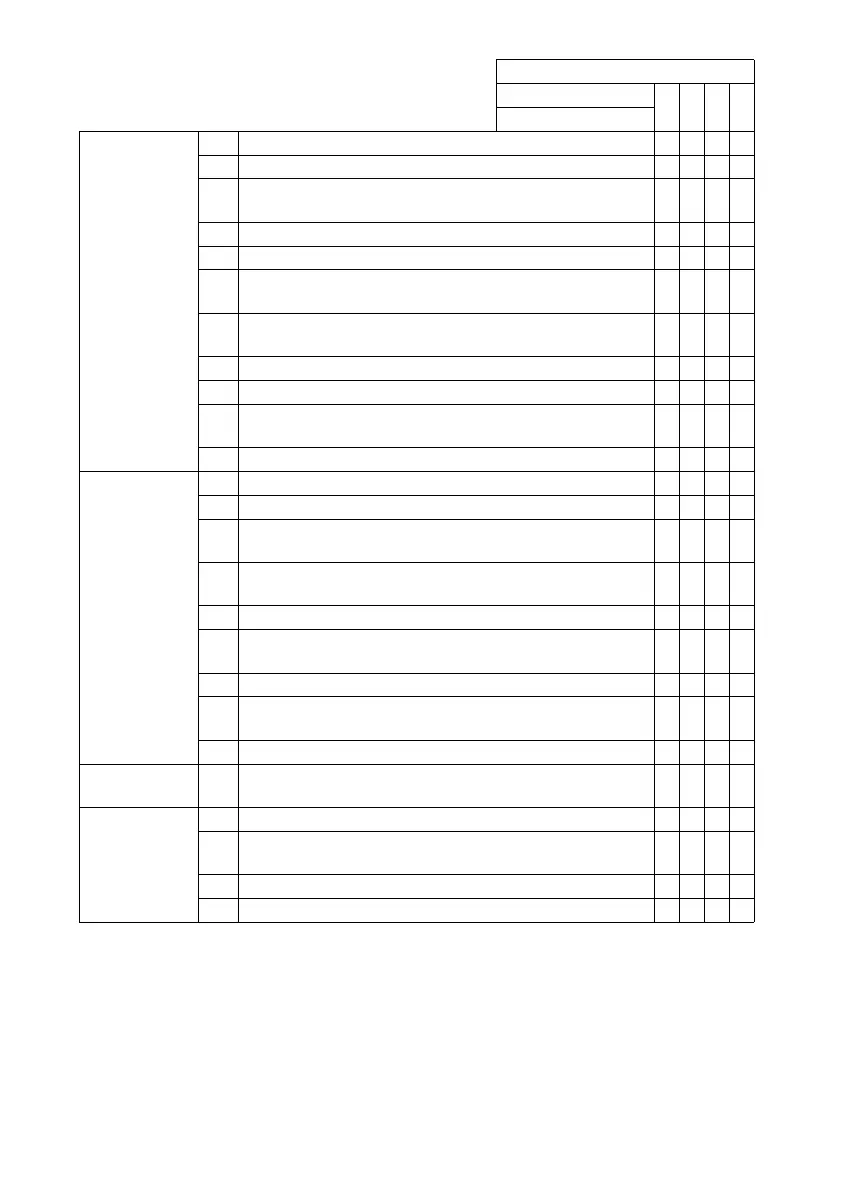

Maintenance intervals

Standard = t WABC

Hydraulic

System

6.1 Test operation t

6.2 Check connections and ports for leaks and damage t

6.3 Check hydraulic cylinder for leaks and damage and

make sure it is secure

t

6.4 Check oil level t

6.5 Test hose guide and check for damage t

6.6 Check ventilation and discharge filter on hydraulic reser-

voir

t

6.7 Replace ventilation and discharge filter on hydraulic res-

ervoir

t

6.8 Replace hydraulic oil and filter cartridge t

6.9 Test pressure relief valves t

6.10 Make sure hydraulic hoses are sealed and check for

damage. p)

t

6.11 Test line brake safety device t

Electrical

System

7.1 Test static charge eliminator t

7.2 Test operation t

7.3 Make sure wire connections are secure and check for

damage

t

7.4 Test the operation of the cable guides and check for

damage

t

7.5 Test operation of warning devices and safety switches. t

7.6 Make sure sensors are fixed, not damaged, clean and

operational

t

7.7 Test operation of instruments and displays t

7.8 Check contactors and relays; if necessary replace any

worn parts

t

7.9 Check fuse ratings t

Electric

Motors:

8.2 Check motor attachment t

Battery: 9.1 Check acid density, acid level and cell voltage t

9.2 Check terminals are securely attached, and apply

grease

t

9.3 Clean battery connections, make sure they are secure t

9.4 Check battery cables for damage, replace if necessary. t

0708.USA

G 8

p) Replace hydraulic hoses after 6 years' operation

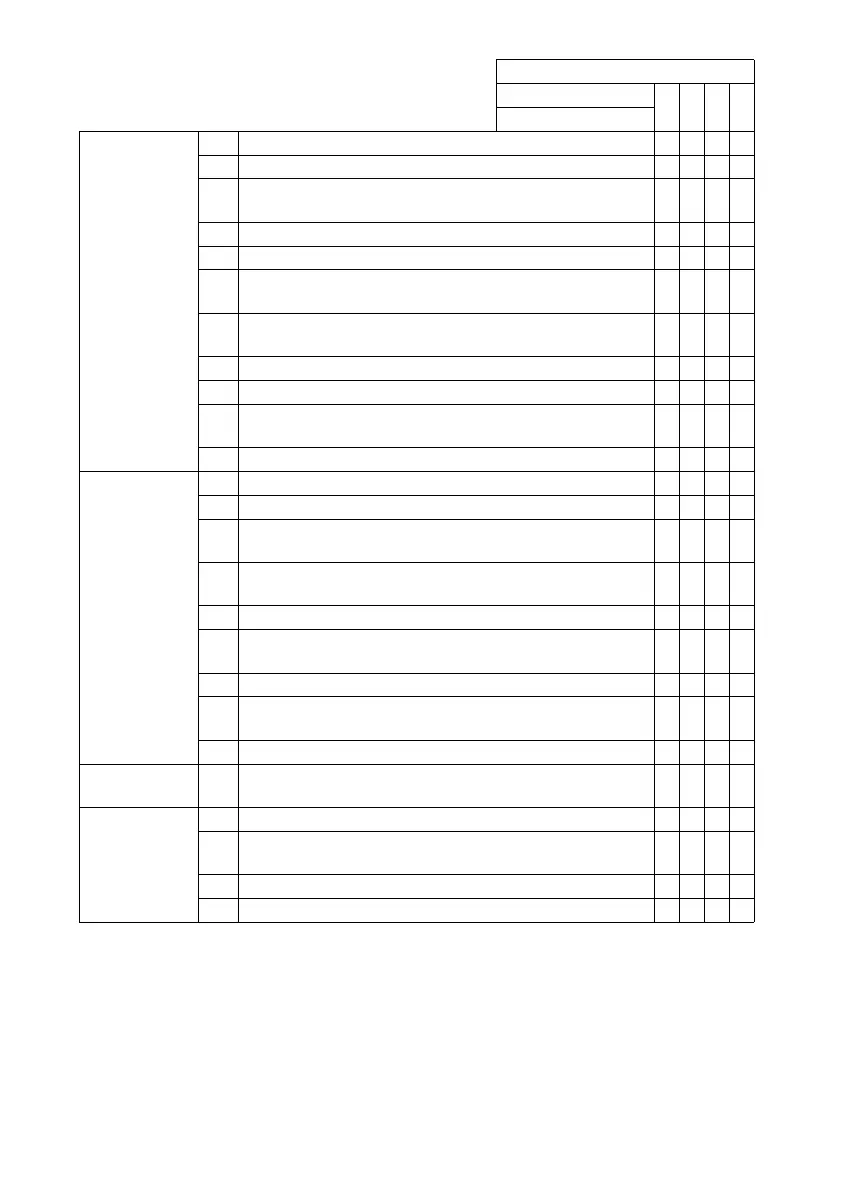

Maintenance intervals

Standard = t WABC

Hydraulic

System

6.1 Test operation t

6.2 Check connections and ports for leaks and damage t

6.3 Check hydraulic cylinder for leaks and damage and

make sure it is secure

t

6.4 Check oil level t

6.5 Test hose guide and check for damage t

6.6 Check ventilation and discharge filter on hydraulic reser-

voir

t

6.7 Replace ventilation and discharge filter on hydraulic res-

ervoir

t

6.8 Replace hydraulic oil and filter cartridge t

6.9 Test pressure relief valves t

6.10 Make sure hydraulic hoses are sealed and check for

damage. p)

t

6.11 Test line brake safety device t

Electrical

System

7.1 Test static charge eliminator t

7.2 Test operation t

7.3 Make sure wire connections are secure and check for

damage

t

7.4 Test the operation of the cable guides and check for

damage

t

7.5 Test operation of warning devices and safety switches. t

7.6 Make sure sensors are fixed, not damaged, clean and

operational

t

7.7 Test operation of instruments and displays t

7.8 Check contactors and relays; if necessary replace any

worn parts

t

7.9 Check fuse ratings t

Electric

Motors:

8.2 Check motor attachment t

Battery: 9.1 Check acid density, acid level and cell voltage t

9.2 Check terminals are securely attached, and apply

grease

t

9.3 Clean battery connections, make sure they are secure t

9.4 Check battery cables for damage, replace if necessary. t

Loading...

Loading...