G 9

0708.USA

e) IG: inductive guidance trucks

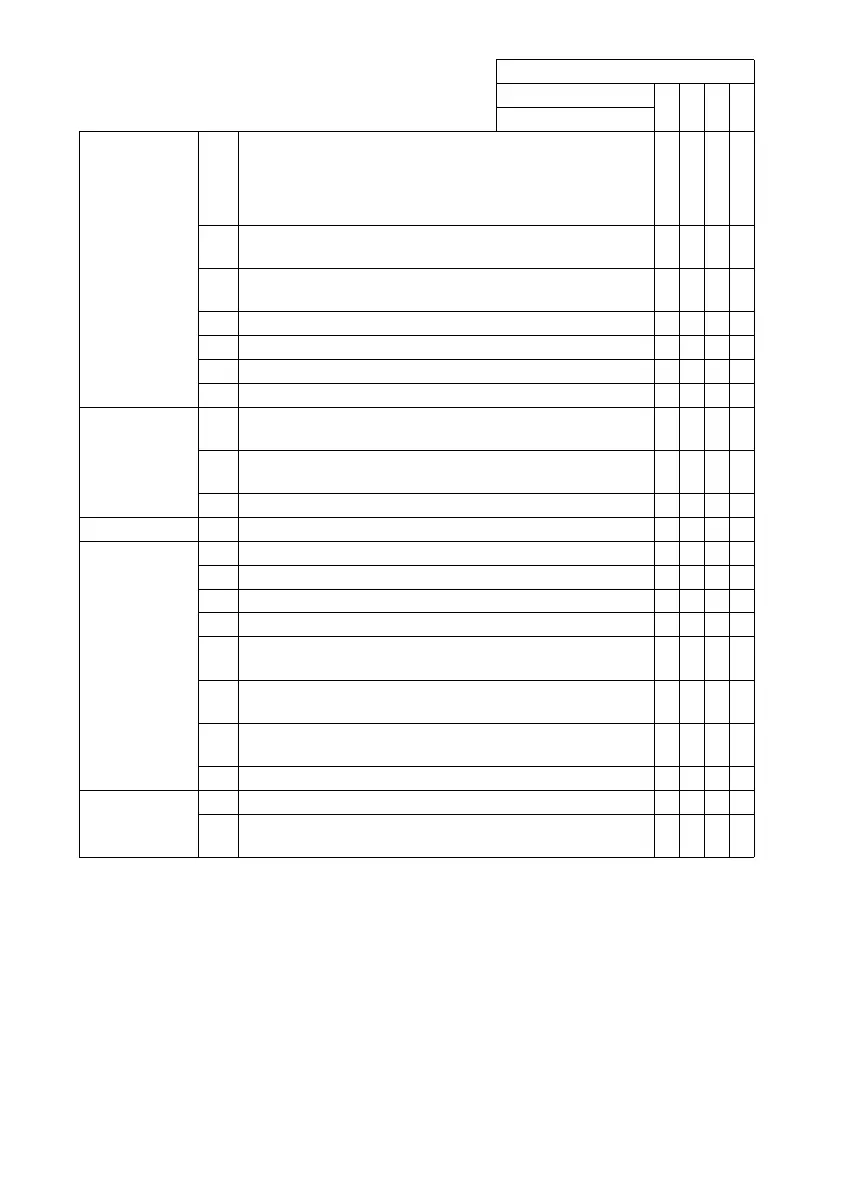

Maintenance intervals

Standard = t WABC

Lift mecha-

nism:

10.1 Clean contact surfaces in the mast sections and apply

grease.

IMPORTANT Attention: Secure Mast as necessary!

t

10.2 Check mast attachments (bearings and retaining

screws)

t

10.3 Check lift chains and chain guide for wear, adjust and lu-

bricate

t

10.4 Lubricate lift chains t

10.5 Visually inspect rollers, slide pieces and stops t

10.6 Check forks and fork carriage for wear and damage t

10.7 Check pallet clamp for wear and damage t

Safety

Devices:

12.1 Check operator safety harness + belts for damage and

wear, and test operation

t

12.2 Check safety harness retaining point for for damage and

wear, and test operation

t

12.3 Check legibility of notices on safety restraint belt. t

Lubrication: 13.1 Lubricate the truck according to the lubrication schedule t

General

Measure-

ments:

14.1 Check electrical system for frame leakage t

14.2 Test travel speed and braking distance t

14.3 Test lift and lowering speeds t

14.4 Test safety devices and cutouts t

14.5 IG: Measure the current in the guidance wire, adjust if

necessary e)

t

14.6 Check travel on the guidance wire, check maximum de-

viation and adjust if necessary e)

t

14.7 Check tracking mode on the guidance wire for aisle

tracking e)

t

14.8 Check wire guidance EMERGENCY STOP operatione) t

Demonstra-

tion:

15.1 Test run with rated load t

15.2 When maintenance is complete, present the truck to the

responsible person.

t

G 9

0708.USA

e) IG: inductive guidance trucks

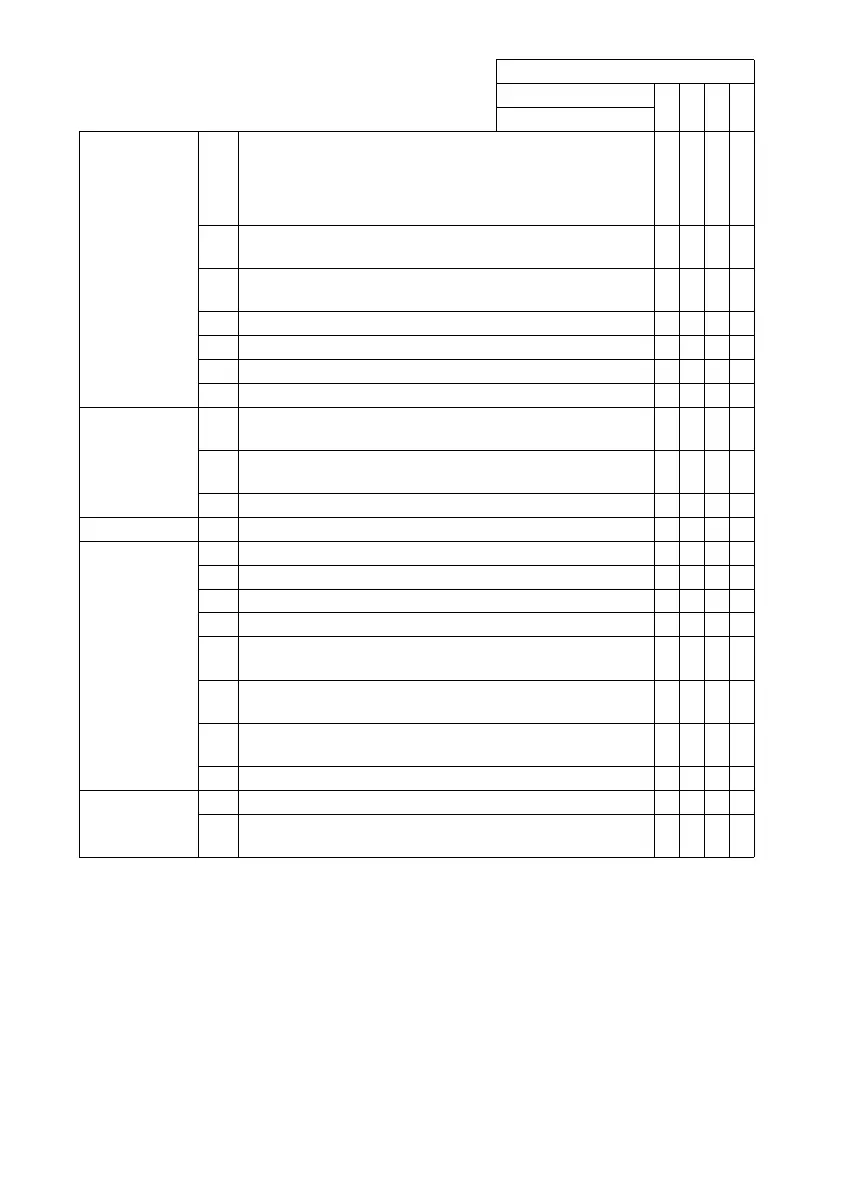

Maintenance intervals

Standard = t WABC

Lift mecha-

nism:

10.1 Clean contact surfaces in the mast sections and apply

grease.

IMPORTANT Attention: Secure Mast as necessary!

t

10.2 Check mast attachments (bearings and retaining

screws)

t

10.3 Check lift chains and chain guide for wear, adjust and lu-

bricate

t

10.4 Lubricate lift chains t

10.5 Visually inspect rollers, slide pieces and stops t

10.6 Check forks and fork carriage for wear and damage t

10.7 Check pallet clamp for wear and damage t

Safety

Devices:

12.1 Check operator safety harness + belts for damage and

wear, and test operation

t

12.2 Check safety harness retaining point for for damage and

wear, and test operation

t

12.3 Check legibility of notices on safety restraint belt. t

Lubrication: 13.1 Lubricate the truck according to the lubrication schedule t

General

Measure-

ments:

14.1 Check electrical system for frame leakage t

14.2 Test travel speed and braking distance t

14.3 Test lift and lowering speeds t

14.4 Test safety devices and cutouts t

14.5 IG: Measure the current in the guidance wire, adjust if

necessary e)

t

14.6 Check travel on the guidance wire, check maximum de-

viation and adjust if necessary e)

t

14.7 Check tracking mode on the guidance wire for aisle

tracking e)

t

14.8 Check wire guidance EMERGENCY STOP operatione) t

Demonstra-

tion:

15.1 Test run with rated load t

15.2 When maintenance is complete, present the truck to the

responsible person.

t

Loading...

Loading...