INSTALLATION, USE AND MAINTENANCE MANUAL – LC

Jurop SpA

Via Crosera n° 50

33082 Azzano Decimo, PN (Italia)

TEL. +39 0434 636811 FAX. +39 0434 636812

http://www.jurop.it

e-mail: info@jurop.it

• Apply the safety requirements indicated in chapter “Safety and

accident prevention” before topping-up.

• Tank capacity: 4l.

Check the oil level in the gearbox

• The oil must be topped-up with the machine stopped and cold.

• Apply the safety requirements indicated in chapter “Safety and

accident prevention” before topping-up.

• The oil level in the gearbox must reach the side discharge hole.

• For the replacement, drain the oil from the gearbox through the

lower discharge plug and top-up through the upper filling plug until it

comes out of the side discharge hole.

Dispose of exhausted oil as provided by current

specification.

• See the table in paragraph 6.1 for the frequency with which to

replace the oil.

• Top up with fresh and clean oil only; use the oil required in

paragraph 2.6 or equivalent.

• During the oil replacement, also replace the discharge plug

washer.

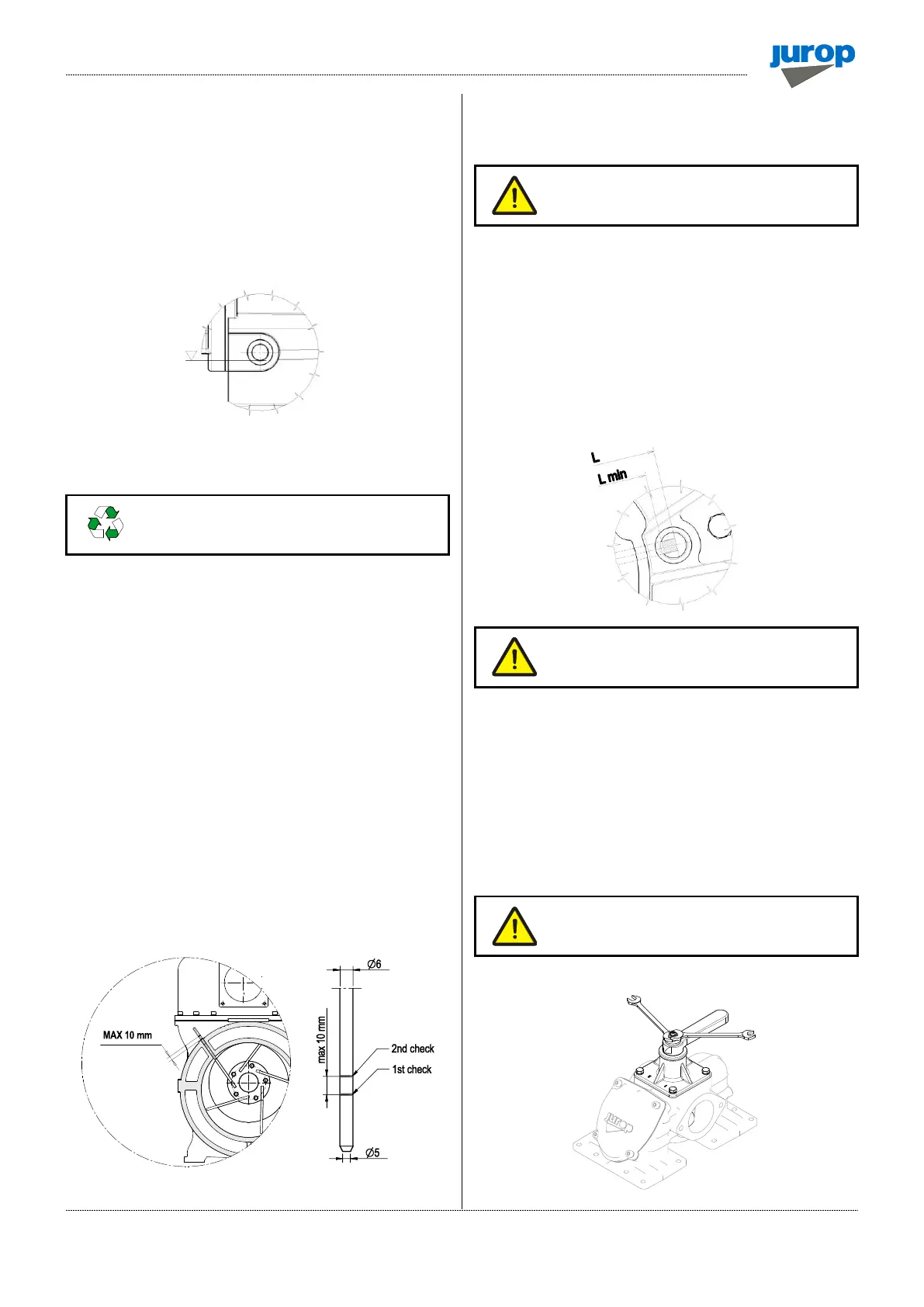

Checking the vanes wear LC 300-420-750

• Unscrew the vanes wear check-plug on the housing (pos. CL).

• Turn the shaft until you see the vane.

• The vanes should slide to the bottom of the seat due to gravity:

check they really do.

• Insert a rod of 6 mm Ø with its conic end towards the pump (rod

supplied with pump).

• Turn the shift manually and touch the outside diameter of the rotor

with the checking rod, mark it a first time. Keep turning the shift till the

rod falls inside a vane groove. Mark it again and measure the gap

between the two marks.

Pic. 6.1

• If this gap exceeds 10 mm, then the vanes must be replaced.

• At the end of this procedure, do not forget to replace the plug.

• Replace all vanes at the same time.

Replace the vanes when their wear exceeds 10

mm (L – L min): they may break. Replace all vanes

at the same time.

Checking the vanes wear LC580

• Unscrew the vanes wear check-plug on the front flange (pos. CL).

• Turn the shaft until you see the vane.

• The vanes should slide to the bottom of the seat due to gravity:

check they really do.

• Replace the vanes when their wear exceeds 10 m\m (L – L min):

they may break.

• At the end of this procedure, do not forget to replace the plug.

• Replace all vanes at the same time.

Pic. 6.2

Replace the vanes when their wear exceeds 10

m\m (L – L min): they may break. Replace all

vanes at the same time.

6.2. Extraordinary maintenance

• Except for the cases described below, extraordinary maintenance

on a LC must be carried out by specialized personnel only; otherwise

the guarantee will be invalidated.

• All extraordinary maintenance interventions must be carried out

when the machine is cold, stopped and switched off. Implement the

safety instructions reported in the “Safety and accident prevention”

Chapter, before performing any maintenance operation.

Follow the safety prescriptions as described in

Cap. “Safety and accident prevention”.

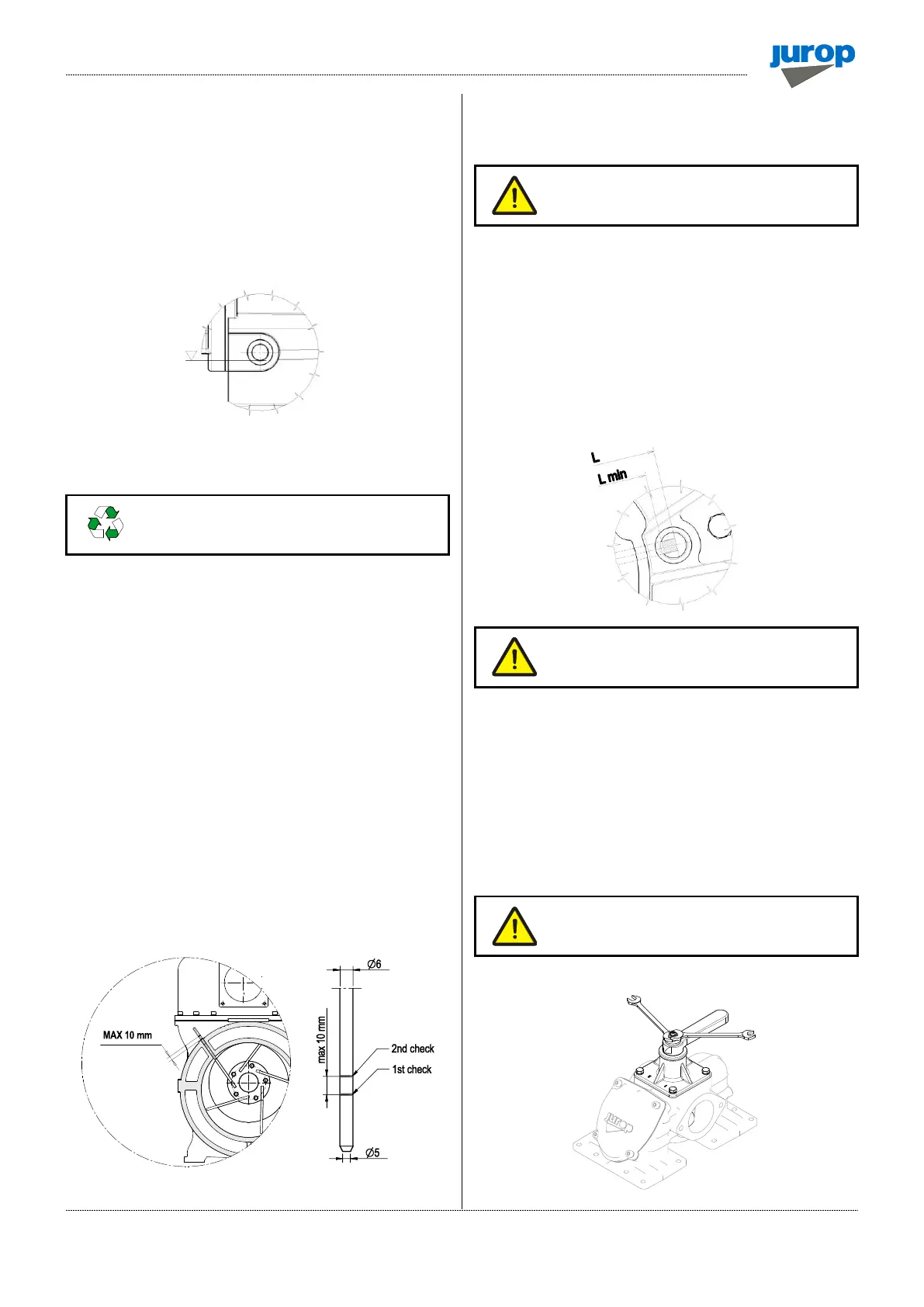

Adjusting the 4-way valve

Pic. 6.3

Loading...

Loading...