Adjusting the pneumatically operated 4-way valve

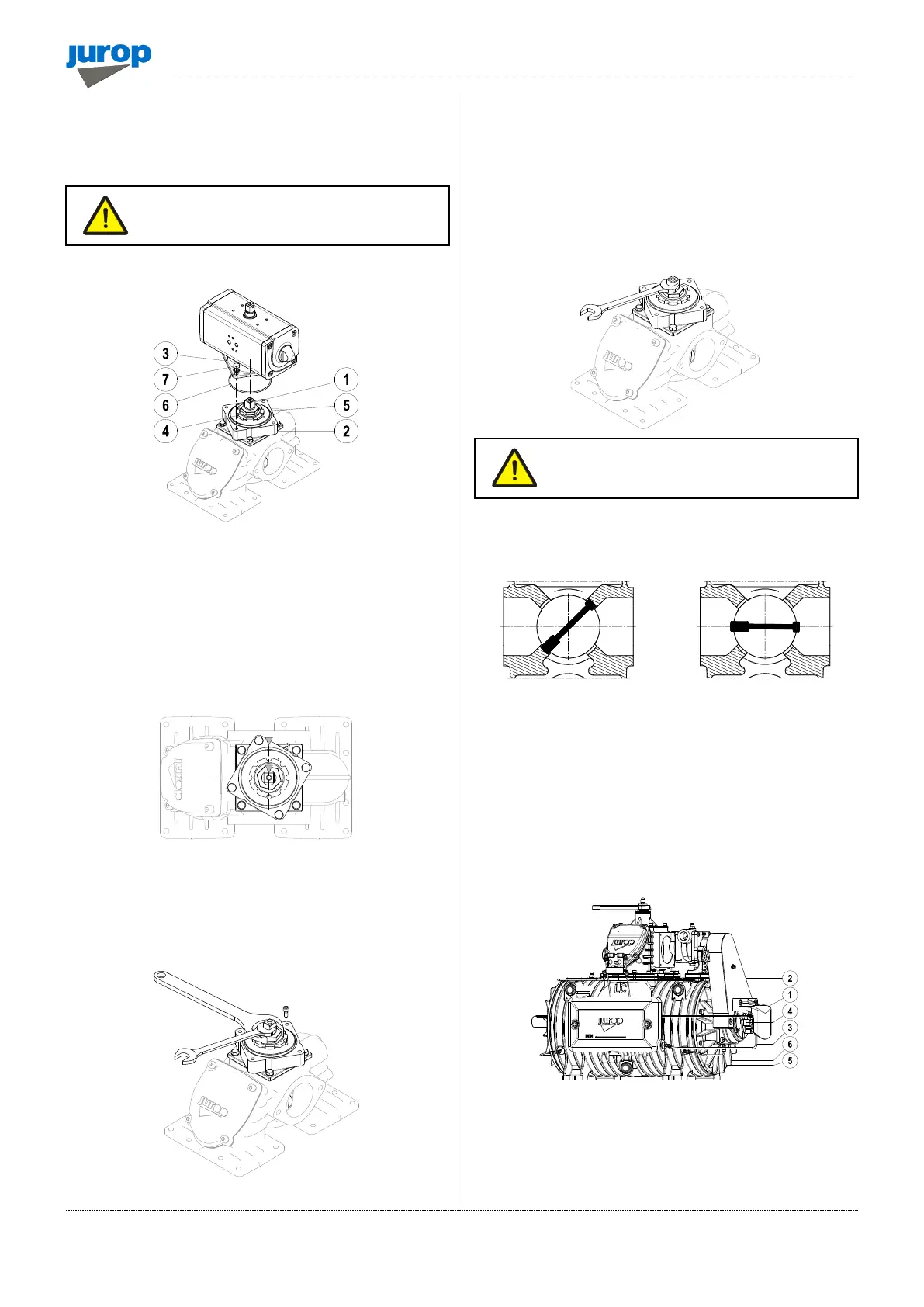

Pic. 6.4

• In case of reduced performance or difficult rotation of the valve in

its seat, it is necessary to adjust the operating play.

• Unscrew the 4 screws M8x16 which fasten the top cover (7) to the

inferior support (2).

• Clean the inner part from the lubricant.

• “Mark” the initial position of the cock (1). When mounting the cock

back in place, it must be in the same position.

• Turn the valve until one of the cock regulation ferrules (5) coincides

with one of the threaded holes on the inferior flange (2). Block

temporarily the nut ferrule with a screw.

• Hold the valve in place with a 17 mm spanner and loosen the nut

(4) over the ferrule by ½ - ¾ turn with a 36 mm spanner.

Pic. 6.5

• Valve adjustment: turn the valve clockwise by 1/8 turn (45°) in

order to lower it (in case of excessive play between the valve and its

seat and of reduced performance) or anticlockwise by 1/8 turn (45°) to

raise it (in case of difficult rotation of the valve in its seat).

• Hold the valve in place with the spanner and fasten the nut (P4)

above the ferrule.

• Remove the screw which temporarily blocks the ferrule and check

for the correct rotation of the valve by adjusting the shaft frame. Repeat

the valve adjustment, if necessary.

Pic. 6.5

• The valve - in both its end stroke positions - must separate the air

flow sucked from the pump outlet air. The pump may be started in

order to check for the proper functioning.

• Lubricate the areas near the ferrule in order to guarantee the

lubrication of parts undergoing wear.

• Set the top cover back into place. Do not forget the OR-Ring (6).

Fasten the 4 screws.

Replacing the vanes

• Remove the vacuum pump from its bearing frame and wash it

before disassembling.

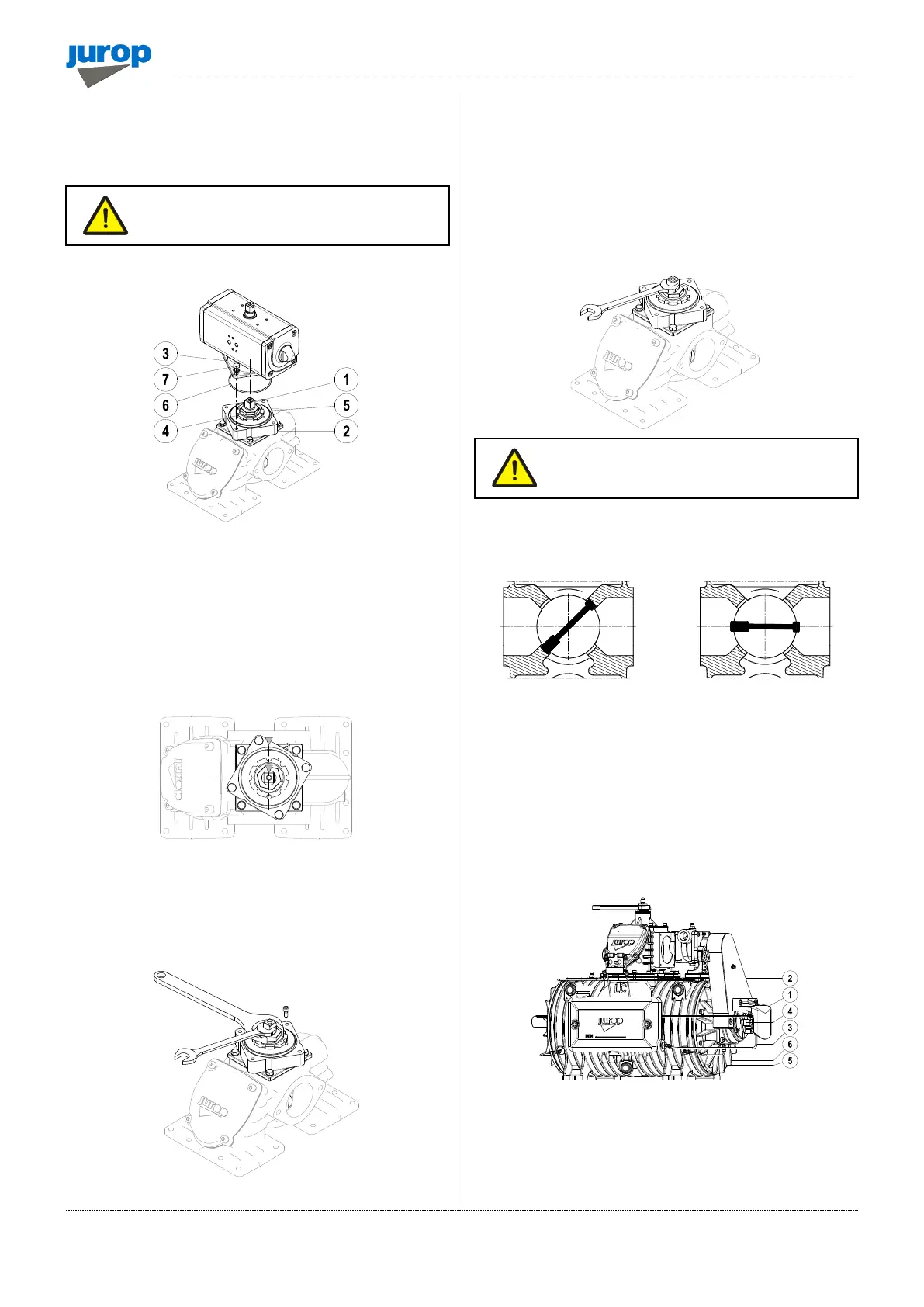

Pic. 6.7

• Drain the cooling liquid from the pump housing.

• Remove the water pump cover (1) and the carter (2).

• Disconnect lubricating pipes (3).

• Remove the lubricating pump (4).

Loading...

Loading...