INSTALLATION, USE AND MAINTENANCE MANUAL – LC

Jurop SpA

Via Crosera n° 50

33082 Azzano Decimo, PN (Italia)

TEL. +39 0434 636811 FAX. +39 0434 636812

http://www.jurop.it

e-mail: info@jurop.it

• Remove the screws (5) fixing the rear flange (6) and use the two

threaded holes to remove the flange – bearing – seal housing. If

necessary, hold the rotor by inserting a wooden block, protecting the

internal bearings from damage.

• Remove the bearing from the rear flange and replace the seal if

broken.

• Lubricate with oil the new vanes before inserting those inside each

groove of the rotor.

• Reinstall all the components in the following order: rear flange, seal

ring, bearing, compensation ring, gasket and flange with lubricating

pump (we recommend to fit correctly the pivot-key on the shaft groove).

• Tighten the nuts (pos. F) by means of a dynamometric wrench

adjusted at 88 Nm.

• Refill the cooling system and re-install the pipeline.

Do not damage components during assembly by

forcing them exceedingly.

• Do not flip the seal ring during rotation of the shaft. Do not leave

foreign objects inside the pump.

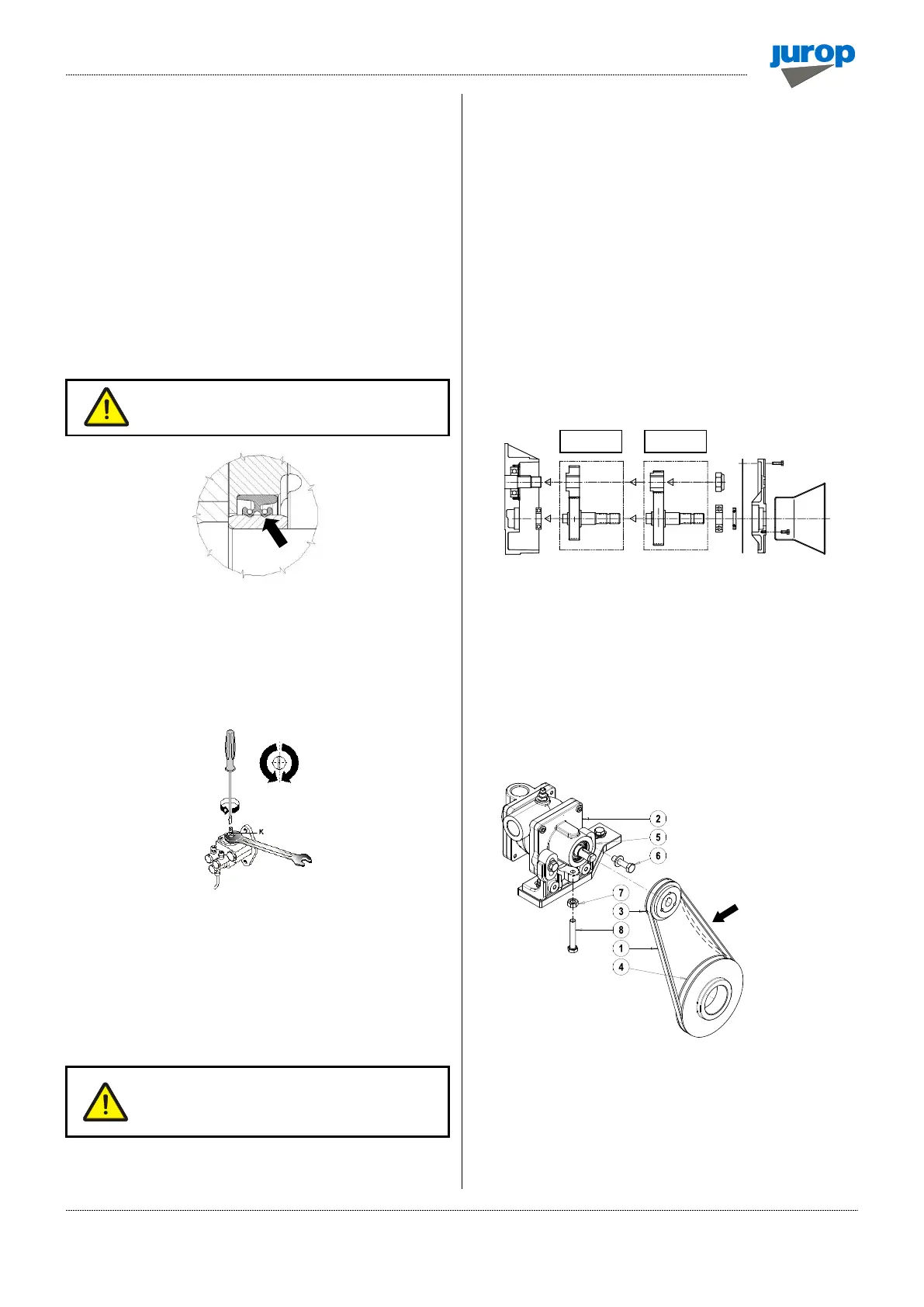

Adjusting the self-lubricating pump

• The automatic lubricating pump is adjusted by the manufacturer

before the shipping.

Pic. 6.8

• If consumption noticeably differs from the indicated value, adjust it

as follows:

− Remove the upper protection cover;

− Using a screwdriver and a 10 mm wrench, adjust the adjusting

screw (K). Close the nut and remount the upper protection cover;

− It is advisable to turn the screw of ¼ of turn and verify the actual

consumption.

Do not reduce oil consumption below the value

indicated in par. 2.3 (for functioning at speeds

different from the maximum, flow is proportionate

to rotating speed).

• ½ turn of the adjusting screw causes a variation in the flow of

approximately 40 - 80 g/h, depending on using conditions.

Replacing gear box components

• The pump with a 540 rpm gear box can be transformed into a

pump with a 1000 rpm gear box (and vice versa):

− Take down the gear box as illustrated. Remove also the drive

shaft’s pinion;

− Install the new pinion closing the nut;

− Mount the gear wheel including bearings and seals on the front

cover, properly aligning components. This housing may now be

installed in the gear box: fit the bearing in the internal housing on

the flange;

− Properly engage gears, replace the cover’s gaskets to complete

gear replacement. Insert the parallel pin, which maintains the

correct alignment;

• See picture below.

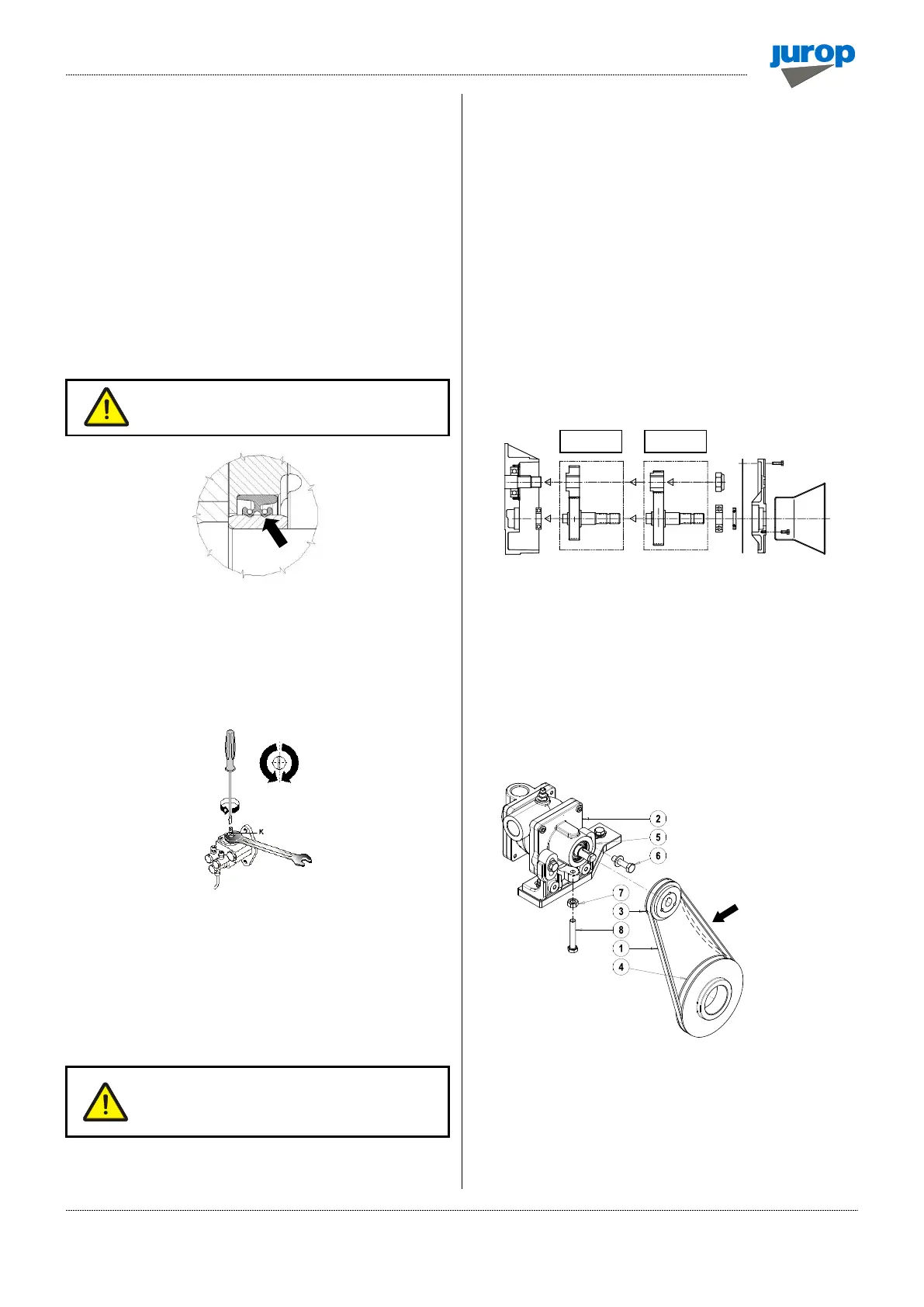

Cooling water pump belt tensioning

• To correctly tension the belt (1), after checking the alignment of

the two pulleys (3-4), loosen the screws (6) and the hexagon nut (7).

• Adjust the screw (8) that acts on the recirculation pump movement

(2) along the vertical axis.

• Once the belt is correctly tensioned (1), tighten the nut (7) and

screws (6).

• See the exploded view at the end of the manual for spare parts.

Pic. 6.9

Loading...

Loading...