http://www.jurop.it

e-mail: info@jurop.it

Attention:

Carefully apply these prescriptions.

3.1. General recommendations

• Installation and maintenance must be carried out with the unit

totally disengaged from its drive system and must be performed by

qualified personnel.

• Use adequate clothing (avoid ties, loose sleeves, necklaces and

so on) and suitable protection equipments (gloves, protection glasses,

boots...).

• When transporting the pump, use proper slinging. Store the pump

in stable places.

• Make sure that all the parts of the unit are idle and cool, before

performing any maintenance operation.

• Before each maintenance operation, stop the pump and restore

the atmospheric pressure.

• When the pump is running, some parts may reach very high

temperatures (above 100°C). Use all necessary precautions to avoid

contact.

• Operators working nearby must avoid prolonged exposure to the

noise emitted by the aspirator, if not equipped with the proper ear-

protection devices.

• Avoid accidental suction of solids: solids may be projected at high

speed through the exhaust manifold and cause injures.

• Do not start the machine if the protection devices provided for

transmissions are removed. Replace damaged parts.

• Pressure relief valve: point the air flux away from the operators.

• Do not use the aspirator over its designed limits: the machine may

be damage and the operator may be injured.

Do not exceed the power supply parameters

indicated in the technical tables (see par. 2.3).

3.2. Intended use

• The vacuum pumps LC are designed to convey filtered air into

systems for the vacuum production or for the suction of powders or

liquid wastes. Any other usage shall be considered improper.

• Do not sack toxic substances and inflammable or explosive

gasses, since the internal components of the pump may reach high

temperatures.

• Liquids or solids infiltrations can seriously damage the pump.

• Do not run the pump over its designed operating limits (see par.

2.3): it may break and transmission can be damaged.

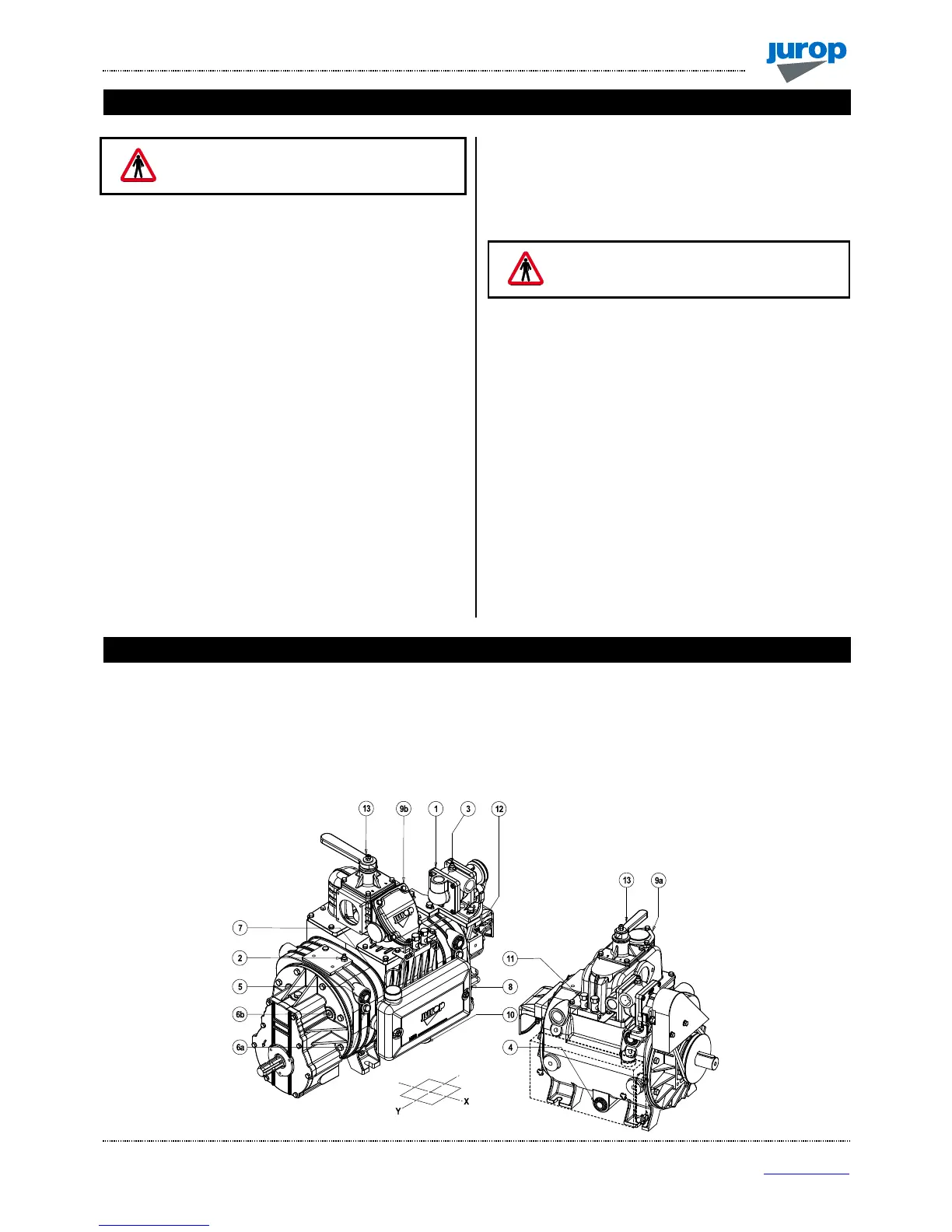

Legend of main components

1. Water recycle pump 6a.

Loading...

Loading...