TECHNICAL SERVICE MANUAL FOR KEMPOWELD

GENERAL MAINTENANCE OF KEMPOWELD

Maintenance of Kempoweld power source will normally consist of general cleaning

of unit with soft brush and vacuum cleaner, and checking of wearing for parts like:

switches,connectors, potentiometers and fuses. NOTE! If you use compressed air

for cleaning, there is a risk that dirt is packed even more tightly into gaps of

connectors or components, so be carefull with those parts!

Maintenance of the wire feeder and mig gun will normally consist of general

cleaning and change of consumable parts like: contact tube, contact tip,

contact tip adapter, gas nozzle, wire conduit, feeding rolls, guide tubes, and gear

wheel.

The number of machines in will determine to what extend consumable- and spare

parts will be stocked.

WARNING

Watch out for the mains voltage! Disconnect the power source from mains voltage

before removing cover plates or any testing or measurement and before

troubleshooting look for signs of over heating, fractures and damages from internal

components and power semiconductors.

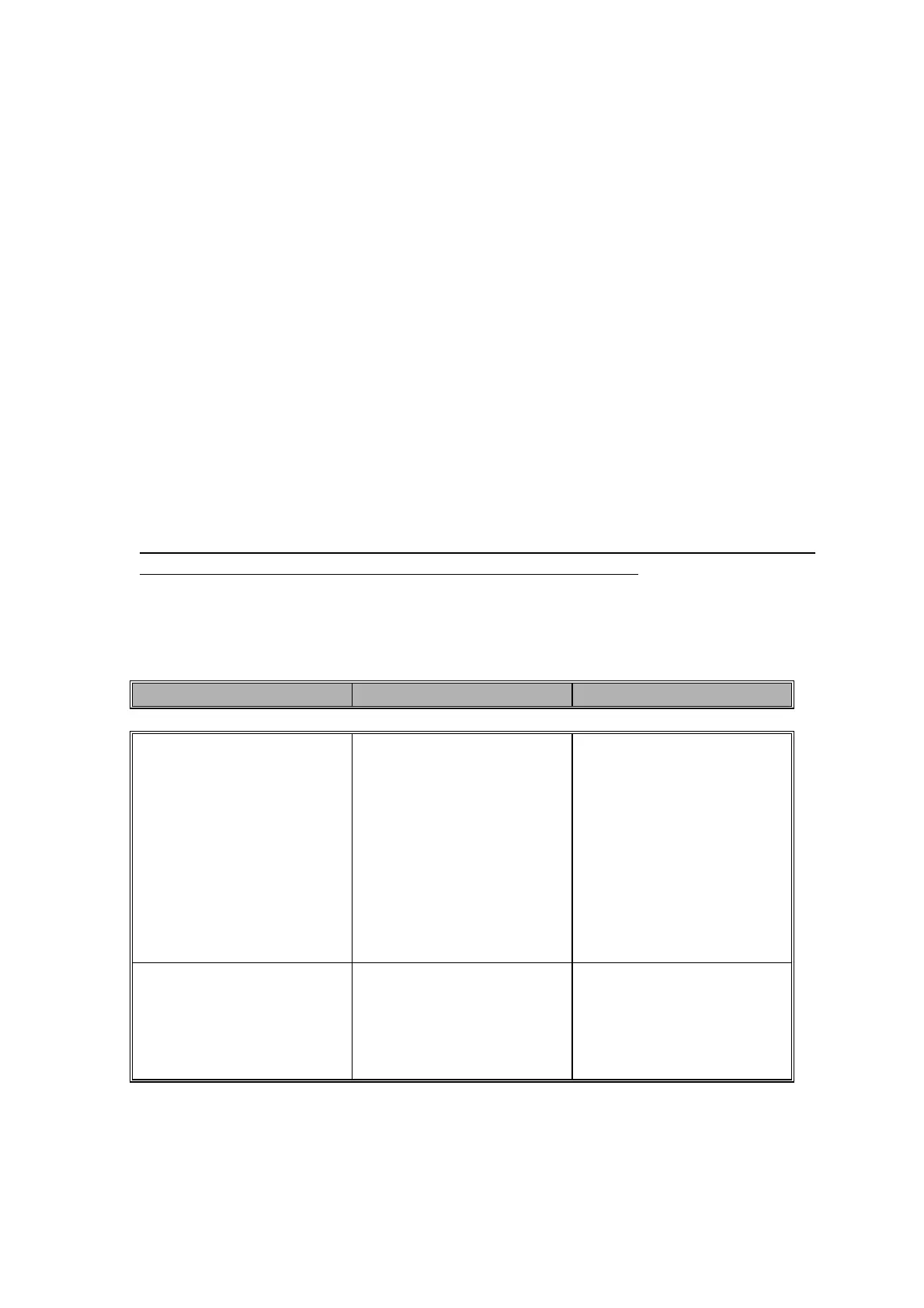

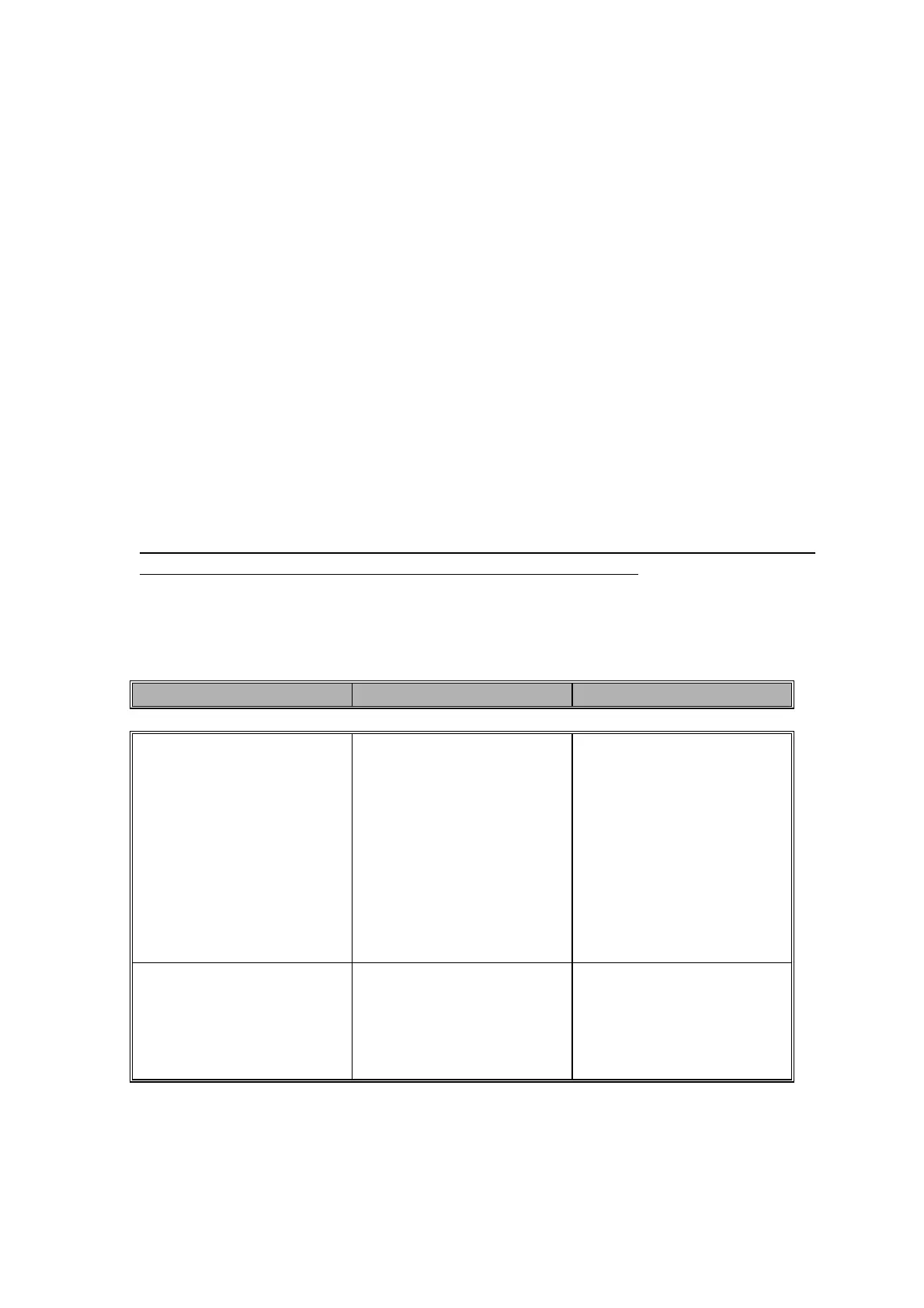

TROUBLESHOOTING CHART

TROUBLE CAUSE REMEDY

The KEMPOWELD won´t start at all,

any of the auxiliary devices won´t

start.The signal lamps of machine

are not switched on.

Blown fuse in mains supply voltage.

Faulty mains cable.

Broken main switch.

Faulty auxiliary transformer T002 or

bad connection in connector X9,

400V or 0V.

Blown fuse F001 8A.

Check all three supply voltage

phases; check fuses.

Check mains voltage from terminal

block X001, repair cable if needed.

Check the main supply voltage

before and after main switch, change

switch if needed.

Check transformer, repair

transformer connection or change

if needed.

Check fuse and change if needed.

The wire feeding unit K200/400

won´t work.

Faulty connection in control lines.

Blown fuse F001 8A.

Broken PCB.

See, TABLE FOR CONTROL

LINES, table 1.

Check/change fuse F001.

See, TROUBLE SHOOTING FOR

PCBs appendix 1.

Loading...

Loading...